A Beginner’s Guide to Bending Processes

In industrial settings, “bending” has two main meanings. One refers to the mechanical force that causes an object to bend, while the other refers to the process of deforming materials.

This article aims to help you take your first step toward understanding bending processes.

Table of Contents

What is Bending Processes?

Bending is the act of applying force to an object to deform it, causing it to take on a bent shape. Generally, when force is applied, the object deforms. If the force is removed, it may return to its original shape. However, if the force exceeds the material’s limits, it may lose its shape or strength, resulting in damage.

Some materials, such as metals, heated plastics, and wood, have a unique property: when force is applied, they deform and do not return to their original shape once the force is removed, nor do they lose their strength. This property is utilized in bending processes.

Materials and Applications for Bending

Bending is widely used in industrial applications, particularly in sheet metal and press work. Here, we’ll explore the materials commonly used in bending processes and their applications.

Metals

Metals are the primary materials used for bending due to their plasticity. Various forms of metal, including sheets and rods, can be processed. Common metals for this processing include iron, steel, stainless steel, aluminum, and copper.

- Sheets: Sheet metal fabrication, press working, corrugated sheets, roll forming, can making

- Rods: Rebar, furniture, construction materials, machine parts

- Pipes: Furniture, construction materials, machine parts

Plastics

Bending in plastics typically involves thermoplastics, which become soft when heated. The material is heated just enough to allow deformation without losing its shape. Common plastics for this processing include acrylic, polycarbonate (PC), PVC, and ABS.

- Sheets: Containers, covers, machine parts

- Pipes: Containers, machine parts

Wood

While less common than metal, wood bending is also practiced, especially in furniture manufacturing, and is known as bentwood processing. This involves applying heat and moisture while exerting force to bend the wood. The processing can be done with solid wood as well as with plywood or laminated wood.

- Sheets: Furniture, building materials, household items

- Rods: Furniture, building materials

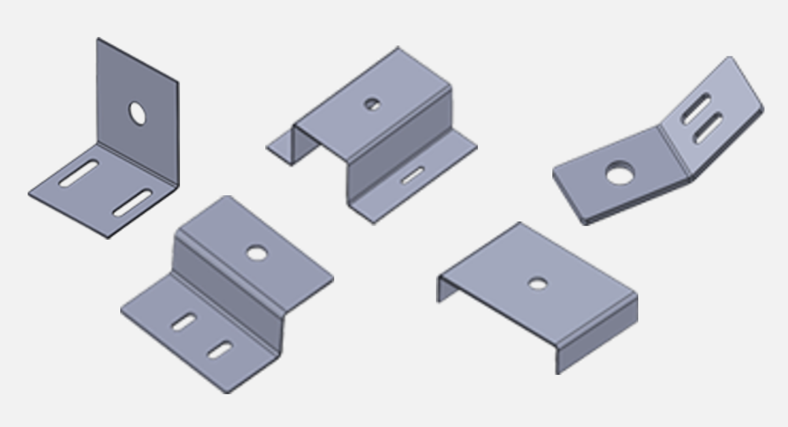

Bending Processes for Sheet Metals

Among the various bending processes, those applied to metals are particularly common. Sheet metal bending is especially prevalent, involving several types of processing.

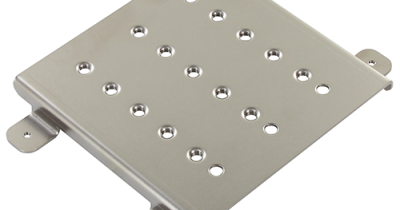

Sheet Metal Fabrication

This involves bending thin metal sheets (typically .27 in or less) using a press brake with general-purpose dies.

Press Working

This uses dedicated dies and press machines to process sheet metal. Everyday items like pots, metal strainers, staples, eyelets, and badges are produced this way, as well as car body panels and machine parts.

Roll Forming

This involves passing metal sheets through three staggered rolls to create a large radius, used for producing large cylinders and pipes.

Can Making

This process creates large structures like tanks, ducts, and frames.

Mechanisms of Sheet Metal Bending

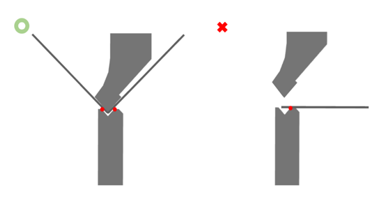

Die Bending

Also known as punch bending, this is the most common method and allows for various shapes like V-bends, U-bends, and L-bends.

Free Bending

This method adjusts the amount of punch descent to customize the angle of the V-bend and is also referred to as partial bending.

Bending processes involve placing the workpiece (the item being processed) on a die and pressing down with a punch. It’s important to note that if the workpiece doesn’t rest on both ends of the die, bending can’t occur.

Conclusion

Bending refers to applying force to deform an object, creating a bent shape. In industrial contexts, metals and plastics are primarily processed, with wood also being used. One type of metal bending is sheet metal fabrication, which involves bending thin sheets using general-purpose dies and press brakes.

meviy Sheet Metal Fabrication

meviy offers not only bending but also laser cutting and punching services, accepting automated quotes and orders based on 3D data. For more details on our materials and services, please check our offerings.