Engineering Plastics Overview

Engineering plastics are specialized resins designed for industrial applications, boasting high strength and heat resistance. They are particularly suitable for industrial uses due to their unique properties. We will explore what engineering plastics are, their characteristics, and how they are classified.

Table of Contents

Understanding Engineering Plastics

Engineering plastics stand out from conventional plastics due to their enhanced features. They are lighter than metals, making them ideal for mass production.

These plastics come in various types and are used across a wide range of applications. They are utilized in mechanical components such as resin gears and automotive headlamps, as well as in a broad range of electrical and electronic components. Additionally, they are commonly used for containers for chemicals and liquids, making them frequently encountered in daily life. Engineering plastics are also found in everyday items such as picture frames and bath accessories.

These plastics often serve as a middle ground between traditional plastics and metals, contributing to lighter designs and cost savings. While there is no strict definition, engineering plastics can typically withstand long-term heat exposure of above 100°C (212°F) and have a tensile strength that exceeds 5,800 psi (40 MPa).

Classification of Engineering Plastics

Molecular Structure

Engineering plastics are categorized based on their molecular structure and applications. There are two main types: crystalline resins and amorphous resins.

Amorphous resins, such as polycarbonate (PC) plastics, derive their transparent appearance from their non-crystalline structure. Crystalline plastics, such as polyacetal (POM) plastics and polyethylene terephthalate (PET), have a more orderly molecular structure, influencing their specific characteristics. This classification aids in understanding their distinct features and assists in selecting the most appropriate material for various applications.

Performance

In addition, among engineering plastics, those with particularly high performance are often referred to as high-performance plastics. These materials are characterized by their exceptional heat resistance, high strength, flame retardancy, and solvent resistance. While there is no precise definition, a common benchmark for high-performance plastics is their ability to withstand temperatures of 150°C (302°F) or higher.

| Crystalline Resins | Amorphous Resins | Applications | ||

|---|---|---|---|---|

| Commodity Plastics | Polyethylene (PE)

Polypropylene (PP) |

Polystyrene (PS) | Outer casings and internal parts (e.g. home appliances and toys) | |

| Engineering Plastics | Standard Engineering Plastics | Polyacetal (POM / Acetal)

Polyethylene Terephthalate (PET) |

Acrylonitrile Butadiene Styrene (ABS)

Polycarbonate (PC) |

Outer casings and internal parts (e.g. machinery, containers and furniture) |

| High-performance Plastics | Polyether Ether Ketone (PEEK)

Polytetrafluoroethylene (PTFE / Teflon) Liquid Crystal Polymer (LCP) |

Polyethersulfone (PES)

Polyetherimide (PEI) |

Containers, furniture, transportation equipment, and products used in the medical field and food manufacturing | |

Features of Engineering Plastics vs. Metals

Advantages:

- Lightweight

- Easy to mass produce

- Exceptional heat resistance

- Strength

Just like other resins, engineering plastics are lightweight and easy to mass-produce in the same shape through injection molding. They also have the advantage of being superior in heat resistance and strength compared to other resins, making them easy to use for industrial purposes.

Disadvantages:

- Higher material costs

- Prone to degradation from ultraviolet radiation, oils, or moisture

- Slightly inferior strength and heat resistance

As with all resins, the cost of the material itself tends to be higher than that of iron. In the case of engineering plastics, the cost of materials is even higher than that of other resins. There are also high-strength engineering plastics, but their strength is inferior to metals, so care must be taken when using them for parts that require strength. Furthermore, depending on the type of engineering plastic, care must be taken regarding dimensional changes that occur due to deterioration or hydrolysis.

Common Processing and Finishers

Injection Molding:

Like general-purpose plastics but requires special attention to mold wear and molding temperature.

Machining:

Suitable for prototyping and specific operations like drilling and gear cutting.

Painting:

Often necessary for parts like electrical enclosures and buttons.

Main Types of Engineering Plastic

- Polycarbonate (PC):

Known for its transparency and impact resistance but less chemically resistant.

- Polyamide (PA / Nylon):

Offers high mechanical strength and wear resistance and can absorb moisture.

- Polyacetal (POM):

Offers high wear resistance and a smooth surface, commonly used for gears and bearings.

- Modified Polyphenylene Ether (m-PPE):

Combines strength with lightness, ideal for electrical device housings. Not solvent resistant.

- Polybutylene Terephthalate (PBT):

Noted for its electrical insulation and smooth surface, commonly used in electrical and automotive parts. Sensitive to hydrolysis.

- Polyethylene Terephthalate (PET):

Polyethylene terephthalate, commonly known for its use in plastic bottles, is lightweight and durable. It is often used as a fiber-reinforced plastic, incorporating materials like glass fibers or carbon fibers for added strength.

- Polyphenylene Sulfide (PPS):

Polyphenylene sulfide, referred to as PPS, is typically reinforced with glass fibers or carbon fibers. It boasts exceptional heat resistance and very high mechanical strength. Additionally, it is flame-resistant, making it suitable for use in high-temperature environments.

- Polyether Ether Ketone (PEEK):

Polyether ether ketone, known as PEEK, is a representative example of a high-performance plastic. It can withstand temperatures over 464°F and has high mechanical strength. PEEK is also notable for its impact resistance and chemical resistance. Furthermore, it does not hydrolyze under high-temperature steam conditions.

Conclusion

Engineering plastics are plastics with higher strength and heat resistance compared to general-purpose plastics. They are often described as having properties that fall between metals and plastics, making them suitable for replacing metal components to achieve weight reduction and cost savings. Due to their excellent properties, they are widely used in mechanical parts and everyday items.

Engineering plastics can be broadly classified into two main types based on their molecular structure. Plastics with additional features such as flame resistance and solvent resistance are often referred to as high-performance engineering plastics.

Commonly used engineering plastics include Polycarbonate (PC), Polyamide (PA), Polyacetal (POM), Modified Polyphenylene Ether (m-PPE), and Polybutylene Terephthalate (PBT). Each type has its own unique characteristics, so they should be selected according to the specific requirements of the application.

What’s meviy?

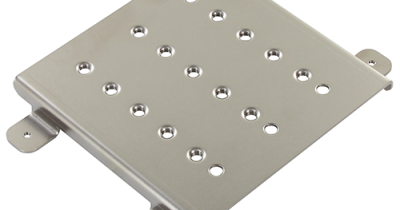

On-demand, fast sourcing of quality custom mechanical parts is made possible by meviy.

meviy is one of the most reliable on-demand manufacturing platforms in the US that allows you to get instant quotes for your mechanical parts simply by uploading 3D CAD data. No longer need to create 2D drawings just to quote parts. This platform supports sheet metal fabrication and CNC machining such as milling or turning and has saved time for over 160,000 mechanical designers and purchasers worldwide.