Explore Black Anodized Aluminum Features

Anodizing, a well-known surface treatment for aluminum, can give its surface a colorful finish. Among these colors, black is one of the most popular due to its ability to impart a sense of luxury and sophistication to the product. The classification of black anodized aluminum into “black” and “matte black” is based on the processing method, with each type having its own unique characteristics and treatments. Understanding each black anodizing type and the appropriate application will help improve the efficiency of future material selection.

Table of Contents

Types of Black Anodized Aluminum

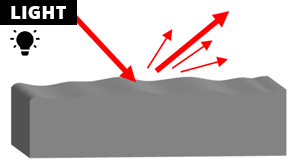

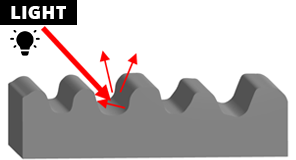

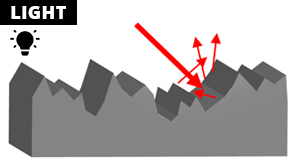

Black anodized parts are originally bright. The anodizing process is complemented by chemical or blasting pretreatment . By adding unevenness to the surface, it loses its luster, resulting in a “matte black” finish.

From left to right: black, matte black with chemical treatment, matte black with blasting treatment.

From left to right: black, matte black with chemical treatment, matte black with blasting treatment.

Pretreatment for “Matte” Black Finish

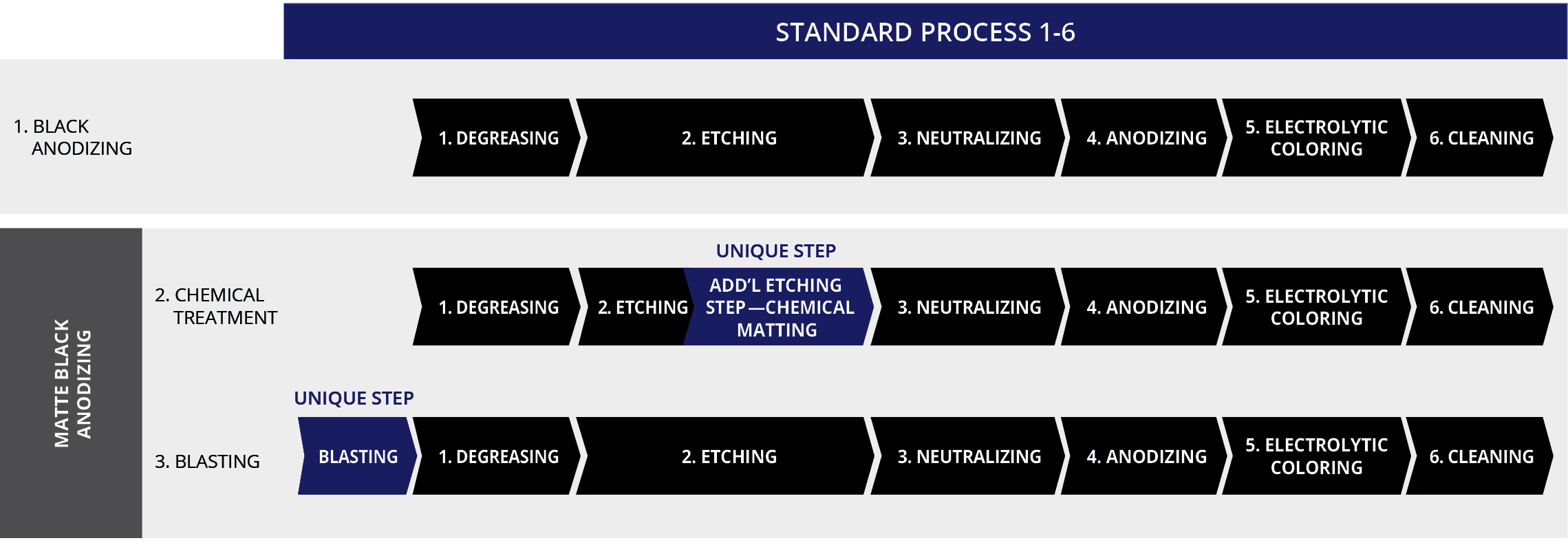

The anodizing process can be broadly divided into the following:

【1】Degreasing,【2】Etching,【3】Neutralizing,【4】Anodizing,【5】Electrolytic Coloring, and【6】Cleaning.

・Black Finish: The process completes in the basic 6 steps.

・Matte Black Finish via Chemical Treatment: After 【2】Etching, a process of preparing the surface and making the finisher easier to apply, it is common to add pretreatment with chemicals for matting (navy blue segment above). In some cases, the etch time can be extended or the chemical concentration increased so that the etching and matting processes are not separated.

・Matte Black Finish via Blasting: Before 【1】Degreasing, a pretreatment by blasting is added for Matte Black Finish. Degreasing (the process of removing oil adhered to the workpiece) (navy blue segment above). Depending on the equipment, Blasting and Decreasing may be performed at the same time.

Differences in Black Anodized Finishes by Method

The differences in the finish depends on the processing method.

| Type | Effect on Processing and Finish Black |

| Black Finish |

|

| Matte Black Finish

(Chemical Treatment) |

|

| Matte Black Finish

(Blasting) |

|

Characteristics of Black Anodized Aluminum

The characteristics of each anodizing process are as follows:

| Low

Reflectivity |

Appearance | Cost | Features | |

| Black Finish | △ | ○ | ◎ | There is a glossy, smooth surface. Eliminating matte pretreatment can lead to cost reduction. |

| Matt Black Finish

(Chemical Treatment) |

○ | ◎ | ○ | There is some reflection, but it is weaker than “black” and has a less glossy finish. There is little color variation. |

| Matt Black Finish

(Blasting) |

◎ | △ | △ | It is not the glossiest of the three types. Uneven color is likely to occur. |

- The symbols ◎, ○, and △ in the table represent the results of comparing the three types of black anodizing: excellent, good, and fair.

- Low Reflectivity: low light reflection

- Appearance: minimal color unevenness due to processing, resulting in a beautiful matte appearance

- Cost: cost effectiveness

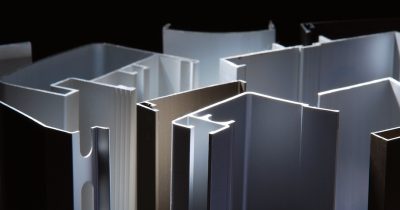

Product Examples

-

Black Finish

Chuck (workholding device)

-

Chemical Matte Black

Sensor Cover

-

Blasting Matte Black

Workholding Table

What’s meviy?

On-demand, fast sourcing of quality custom mechanical parts is made possible by meviy.

meviy is one of the most reliable on-demand manufacturing platforms in the US that allows you to get instant quotes for your mechanical parts simply by uploading 3D CAD data. No longer need to create 2D drawings just to quote parts. This platform supports sheet metal fabrication and CNC machining such as milling or turning and has saved time for over 160,000 mechanical designers and purchasers worldwide.