Laser Engraving: What It Is, How It Works, and Why You Should Use It

In the world of modern manufacturing and customization, laser engraving has become a go-to method for producing detailed, permanent marks on a wide variety of materials. Whether you’re a product designer, manufacturer, or hobbyist, understanding how laser engraving works—and what it can do for you—opens up a world of precision and creativity.

What is Laser Engraving?

Laser engraving is a precise process that uses a high-powered laser beam to remove material from the surface of an object, creating a deep, permanent mark. Unlike laser etching or marking, engraving actually removes a small portion of the material, leaving a clean, indented design.

How Does Laser Engraving Work?

The engraving process involves the following steps:

- A laser beam is directed at the material using mirrors and lenses.

- The laser heats the surface to extreme temperatures, removing the material in the path of the beam.

- This creates a permanent groove or cavity that forms text, patterns, or images.

Laser engraving is controlled by software that allows for high precision and customization—perfect for intricate logos, barcodes, serial numbers, and decorative elements.

Materials Compatible with Laser Engraving

Laser engraving works on a wide range of materials:

Metals

- Stainless Steel

- Aluminum

- Brass

- Copper

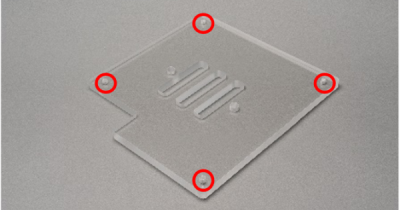

Plastics

- Acrylic

- ABS

- Polycarbonate

- Acetal

- Nylon

Other Materials

- Wood

- Leather

- Glass

- Stone

- Ceramics

Advantages of Laser Engraving

High Precision

Laser engraving offers extreme accuracy, allowing for fine detail and crisp results on even the smallest surfaces.

Permanent and Durable

Engraved marks are resistant to wear, abrasion, chemicals, and high temperatures—ideal for industrial and outdoor use.

Fast and Automated

With CNC-controlled systems, laser engraving is fast, repeatable, and perfect for high-volume production runs.

No Tool Wear or Replacement

As a non-contact process, there’s no physical tool to wear out, meaning low maintenance and consistent quality.

Customizable for Branding and Aesthetics

From logos and part numbers to decorative patterns, laser engraving is great for product personalization and branding.

Common Applications of Laser Engraving

Laser engraving is widely used in various industries:

- Industrial Manufacturing – Marking part numbers, serial codes, and traceability info

- Aerospace & Automotive – Engraving engine parts and data plates

- Medical Devices – Permanent, sterilizable part IDs

- Electronics – PCB labeling and component identification

- Consumer Products – Personalized gifts, jewelry, and gadgets

- Signage & Awards – Trophies, nameplates, and business signs

Laser Etching: What It Is, How It Works, and When you should use it

Laser etching has become a go-to solution for high-precision marking across industries—from manufacturing and aerospace to electronics and medical devices. We will break down what laser etching is, how it works, what materials it supports, and why it’s a smart choice for modern product development.

What is Laser Etching?

Laser etching is a process that uses a focused laser beam to melt and slightly raise the surface of a material, leaving behind a permanent, high-contrast mark. Unlike laser engraving, which removes material, laser etching alters the surface texture without cutting into it.

This technique is a sub-process of laser marking and is ideal for detailed designs, serial numbers, barcodes, logos, and traceability features.

How Does Laser Etching Work?

- A laser beam is directed at the material’s surface.

- The intense heat melts a thin layer, creating a raised, tactile mark.

- As the material cools, the mark hardens, resulting in a durable and permanent contrast.

Since it doesn’t penetrate deeply, laser etching is fast, precise, and perfect for delicate or thin materials.

Materials Compatible with Laser Etching

Laser etching works on a wide variety of materials:

Metals:

- Stainless Steel

- Aluminum

- Brass

- Copper

Plastics:

- ABS

- Polycarbonate

- Acrylic

- Nylon

- Polyethylene

Other Materials:

- Glass

- Ceramics

- Anodized and painted surfaces

Different materials produce different effects (e.g., dark marks on metals or color changes on plastics), but the end result is always clear and permanent.

Advantages of Laser Etching

High-Speed Marking

Laser etching is faster than traditional engraving, making it ideal for high-volume production lines.

Durability

Marks are permanent and resistant to wear, abrasion, and chemicals.

No Contact = No Tool Wear

The laser never touches the material, reducing tool wear and maintenance costs.

High Precision

Laser etching offers incredible detail, perfect for small text, barcodes, and intricate logos.

Eco-Friendly

No inks, chemicals, or additional materials are required—just clean, efficient marking.

Common Applications of Laser Etching

Laser etching is used across many industries for both function and branding:

- Industrial Components – Part numbers, tracking codes

- Electronics – Marking circuit boards, casing details

- Medical Devices – Surgical tools, implant traceability

- Aerospace – Durable ID tags, quality assurance marks

- Automotive – VIN numbers, dashboard components

- Consumer Goods – Jewelry, custom engraving, promotional products

Laser Etching vs. Laser Engraving vs. Laser Marking

| Feature | Laser Etching | Laser Engraving | Laser Marking |

| Surface Impact | Melts surface | Removes material | Alters color/structure |

| Depth | Shallow | Deep | No depth |

| Speed | Fast | Slower | Very fast |

| Durability | High | Very high | Medium–high |

| Applications | Marking codes, logos | Heavy-duty ID, deep logos | Electronics, branding |

Why Laser Etching and Engraving is Important for Modern Manufacturing

With increasing demand for traceability, branding, and regulatory compliance, laser engraving and etching provides a reliable, cost-effective, and scalable solution.

Whether you’re customizing products or marking critical components for traceability, laser engraving and etching delivers clean, consistent results—every time.

Ready to Explore Laser Engraving for Your Project?

From prototypes to production runs, laser engraving offers unmatched speed, precision, and flexibility. Contact us today at meviy-usa@misumiusa.com to get started!