Material Introduction:

Clear Resins’ Features

Clear resins are part of the synthetic resin family, easily recognized for their ability to reduce light reflection and absorption, thus allowing light to pass through their surface.

Let’s delve into the various features, types, and primary uses of clear resins.

Table of Contents

Features and Applications

Since their introduction in the 1930s, the features of clear resins have rapidly gained popularity. While their main properties may vary depending on the resin type, all clear resins typically share these characteristics: they are highly transparent, lightweight, impact-resistant, and easier to mold than glass.

Due to their remarkable properties, they were initially used in the aircraft industry to create more efficient windshields. Their use has since broadened to include various applications across different industries. For example, clear resins are used in containers for liquids, such as water tanks and drink bottles, in automotive lighting fixtures, and in optical devices like eyeglass lenses.

However, not everything is perfect. Despite their advantageous properties, clear resins have some flaws that make them less effective in certain areas.

These disadvantages include:

- Being less heat-resistant (some types may also be flammable)

- Sensitivity to friction and scratches

For instance, acrylic resins, known for their excellent performance in many industries, are easily flammable. Therefore, their use must be carefully considered.

Processes Commonly Used

Clear resins can be processed in various ways to alter their main features and ensure the final product meets customer needs. Here are some examples:

Injection Molding

This process is mainly used for acrylic and polycarbonate resins, which are thermoplastic. These are similar to commodity and engineering plastics, but care must be taken, as the mold wears more quickly and the resin’s transparency may be compromised by galling and welding.

Cutting

Clear resins are often machined from solid. Precision parts like optical components and complex horizontal hole shapes, which are challenging to produce by injection molding, are often machined this way. Clear resin is also cut and polished to a finish when making transparent or visualized models of machine parts.

Polishing

Polishing can enhance the transparency of clear resins. In some cases, such as plastic lenses and parts requiring a glossy finish, cutting is followed by polishing. This process, not often performed on other resins, is somewhat unique to clear resins.

Typical Clear Resins and Their Characteristics

There are various clear resins on the market, but here are five particularly common in major industries:

Acrylic Resin (Polymethylmethacrylate; PMMA)

Acrylic resin is also known as acrylic, or polymethylmethacrylate (PMMA), and is the most transparent of all. They offer higher transparency than glass and are highly durable, impact-resistant, and often used where both transparency and strength are required, such as in aircraft windshields and aquarium tanks. They have excellent machinability and can be used to make transparent models of machine parts. Bending and gluing are also possible. However, they are less resistant to chemicals and scratches.

Polycarbonate (PC)

Polycarbonate is one of the most impact-resistant clear resins. Its transparency is second only to acrylic resins, and it is also resistant to heat, cold, and even fire. It’s used in police shields, spectacle lenses, and optical fibers. The downside is that the resin flows less smoothly when heated or melted, shortening the mold’s life and requiring specialized design. It’s also weak against alkalis and may crack when exposed to detergents.

Polyethylene Terephthalate (PET)

Well-known for its use in PET bottles, this material is less transparent but lighter and more impact-resistant than acrylic resins. It’s also used for food trays, machine covers, and films. It produces fewer toxic fumes when burned and is among the more environmentally friendly resin materials. However, it’s not as resistant to heat.

Polyvinyl Chloride (PVC)

Available in soft and hard variants, PVC, also known as salt bismuth, includes soft polyvinyl chloride (soft vinyl). It’s highly processable and is widely used in everyday life as a general-purpose resin. It’s cheaper than other clear resins, making it suitable for cost reduction. However, it’s prone to damage by cold and light, leading to cracking and deformation. It’s also weak against organic solvents.

Polystyrene (PS)

Used in Styrofoam and food trays, PS can be injection molded without a blowing agent. There are two types: general-purpose polystyrene (GPPS) and high-impact polystyrene (HIPS). Characterized by high transparency, low material cost, and excellent formability, PS is used for packaging materials like CD cases. However, its impact resistance and strength are limited, and it’s not very chemical-resistant.

Choosing the Right Clear Resin Plates

Clear resins are some of the most versatile and widely used materials across various industries in the United States. As discussed in “Clear Resins’ Features,” there are several types of clear resins available for both sheet metals and machining. Each type offers unique characteristics to meet specific requirements. This article will explore the differences between the four main clear resins and their applications in clear resin plates.

Material Comparison

This article focuses on the characteristics and applications of the four most popular types of clear resin plates: PET, acrylic, PC, and PVC. The comparison table below summarizes the features of these four materials.

Additionally, the table provides detailed reference values for light transmittance and ambient operating temperature. These factors are crucial for judging transparency and heat resistance when comparing and selecting materials.

| Materials | ||||

|---|---|---|---|---|

| PET | Acrylic | PC | PVC | |

| Features |

|

|

|

|

| Common Applications |

|

|

|

|

| Recommended Use |

|

|

|

|

| Disadvantages |

|

|

|

|

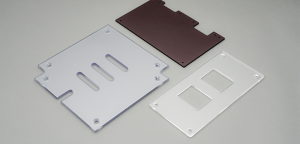

meviy Sheet Metal

Clear Resin Plates

meviy has incorporated clear resins into its portfolio for custom mechanical parts to meet customer demand. With meviy, you can access clear resin plates with short sides ranging from 10 to 1000mm, long sides from 10 to 2000mm, and plate thicknesses of about 3.0 and 5.0mm.