Material Overview for Engineering: PET

Polyethylene terephthalate, commonly known as PET, is a versatile, transparent resin that is widely used in both daily life and industrial fields. This article delves into the applications and characteristics of PET, and the distinctions of PET from other similar materials.

Table of Contents

What is PET?

PET is a resin formed by combining terephthalic acid and ethylene glycol. Recognized globally as the most widely used resin, PET is found in various items, such as PET bottles, clothing, food trays, industrial films, magnetic tapes, and more.

Invented in the United Kingdom in 1941, the manufacturing process of PET commenced in 1948, and PET was initially sold as polyester. Different countries have different trademarks for PET; in the United States, it is known as “Dacron” under DuPont’s trademark. In Japan, it is jointly trademarked as “Tetoron” by Teijin and Toray. In the UK, it is also referred to as “Terylene.”

Main Applications of PET

PET is notably used in the food industry, with PET bottle production having started in Japan in 1977. The lightweight and shatter-resistant nature of PET bottles provided significant advantages over the previously prevalent glass bottles.

There are different grades of PET depending on the application, and names and handling grades may differ between material manufacturers, so it is advisable to check with the manufacturer’s catalog.

Synthetic Fiber

PET serves as a widely used synthetic fiber, commonly known as polyester, constituting approximately 30% of all synthetic fibers. Renowned for its soft touch and excellent heat retention, polyester is extensively used in clothing items such as fleece, sweaters, and shirts. Beyond clothing, its durability and quick-drying properties make it suitable for curtains, carpets, ropes, tents, outdoor sheets, and various other applications. Different grades of PET exist based on catalysts and polymerization methods when used as a synthetic fiber.

Engineering Plastic

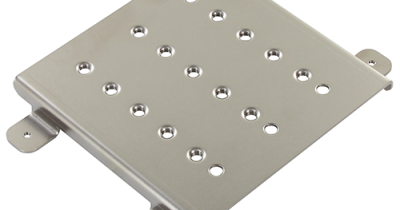

PET used for industrial purposes is classified as engineering plastic, a high-performance plastic employed in various applications, including films, magnetic tapes, electronic components, electrical product housings, partitions, displays, and more. Additionally, it is frequently used to create Fiber Reinforced Plastics (FRPs), where glass fibers are added for reinforcement. Glass Fiber Reinforced PET (GF-PET) is a lightweight, yet durable material utilized in automotive components. Engineering plastic is also available in plate form for use as machine and cutting materials.

Food Containers

One of the primary applications of PET is in the production of food containers, including PET bottles, plates, egg packs, and more. The reasons for its popularity in food containers include its high transparency, ease of molding, and lightweight nature. Moreover, food containers made from PET are easily recyclable, contributing to recycling efforts in many countries.

Advantages of PET

Cold resistance

PET endures temperatures as low as –60°C (–76°F).

Transparency

PET exhibits high transparency, making it suitable for applications such as food containers and industrial films where the visibility of contents is essential.

Water resistance

The material is not prone to deformation due to moisture, making it suitable for liquid containers.

Electrical insulation

PET has a high electrical insulation capacity, with an arc resistance of 90–120 seconds, surpassing general-purpose plastics.

Environmental impact

PET is easily recyclable, making it a material with a relatively low environmental impact.

Disadvantages of PET

Low impact resistance

When used as an engineering plastic, reinforced variants, often incorporating glass fibers, are commonly employed.

Hydrolyzed depending on conditions

PET is subject to hydrolysis at high temperatures or in alkaline atmospheres.

Weak to acids

When using PET in environments where acid resistance is important, caution should be exercised because PET is sensitive to acid.

Differences to Other Plastics — PE, PVC, PP

Vs Polyethylene (PE)

Polyethylene (PE) is known for chemical resistance and electrical insulation, and PE is used to make containers and vinyl bags. It is softer and more susceptible to damage than PET. It also has a lower transparency than PET.

Vs Polyvinyl Chloride (PVC)

Polyvinyl chloride (PVC) is well-balanced in terms of electrical insulation, flame resistance, and weather resistance. However, PVC has a lower heat resistance compared to PET. PET can endure temperatures of around 150°C (302°F), while PVC softens at approximately 70–80°C (158–176°F). PVC also has a lower transparency than PET.

Vs Polypropylene (PP)

Polypropylene (PP) is more cost-effective than PET but excels in heat resistance and chemical resistance. However, PP is more vulnerable to impact than PET, particularly at low temperatures. Additionally, PP tends to whiten under UV exposure.

Conclusion

PET is an extensively used resin worldwide. This material, made with terephthalic acid and ethylene glycol undergoing a chemical reaction at high temperatures, is widely used in daily life in items such as PET bottles and polyester. In industrial applications, PET finds use in films, magnetic tapes, and electronic components. While possessing excellent properties including heat resistance, cold resistance, chemical resistance, and electrical insulation, PET falls short in impact resistance. Hence, in industrial applications, PET is often used to create Fiber Reinforced Plastics (FRPs), which incorporate glass fibers for reinforcement. Although PET is fundamentally a high-heat-resistant material, caution is needed, as it deforms at around 50°C (122°F) when used in PET bottles. Similar materials include PE, PVC, and PE.