Milled Parts Design Tips:

How to Slash Production Costs

Cost-cutting is one of the key factors engineers and mechanical designers must consider when developing new components. In this guide, we will deepen your understanding of how to reduce costs for your milled components and present several design tips that can save you up to 50% on your final component cost. By focusing on key factors that affect the final price—like the diameter of the end mill and the setup time needed to complete the part—you’ll discover more effective design strategies that can help you save costs.

Table of Contents

Factors Affecting Milled Part Cost

High-Cost Factors

Processing time is extended because smaller amounts of material are removed with each pass.

Longer Setup Time

Frequent reattachment of the workpiece to the processing machine and frequent replacement of cutting tools are required.

Low-Cost Factors

Processing time is shorter due to the larger volume of material removed with each pass.

Shorter Setup Time

Fewer reattachments of the workpiece to the processing machine and fewer tool replacements are needed.

Milled Part Design Tips to Cut Costs

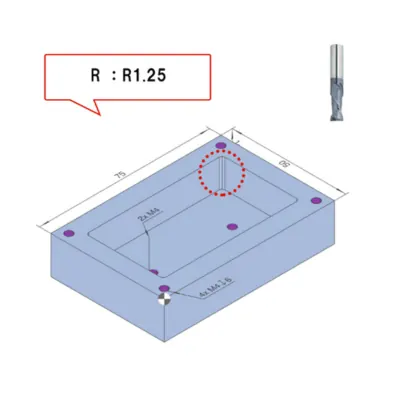

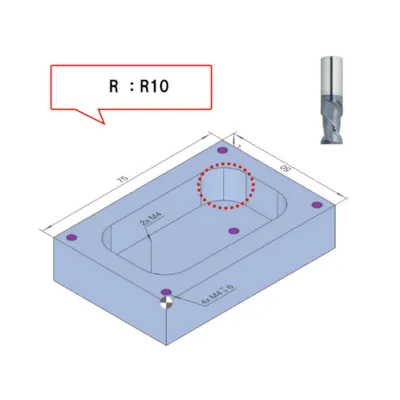

Increasing the Corner Radius

In this example, the corner radius of a pocket is enlarged to reduce the sharpness of the corner. By so doing, a larger-diameter end mill can be used during machining, which results in faster processing times and lower production costs. The specific increase in the radius will depend on the requirements and specifications of the part being fabricated.

This is an important factor in reducing production costs. As we can see from the milling part below, the final cost per unit is reduced by about 50% by making the inner corners easily machinable with a larger diameter end mill.

When quoting with meviy,

Ship to days: 8 days

Cost per unit: $160.46 to $81.07 *

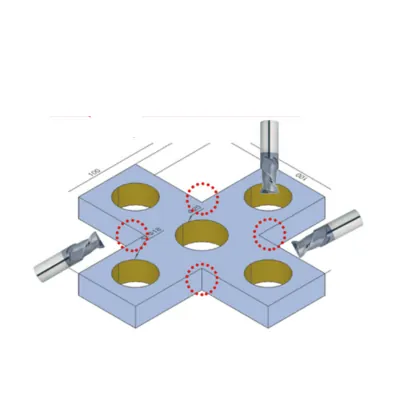

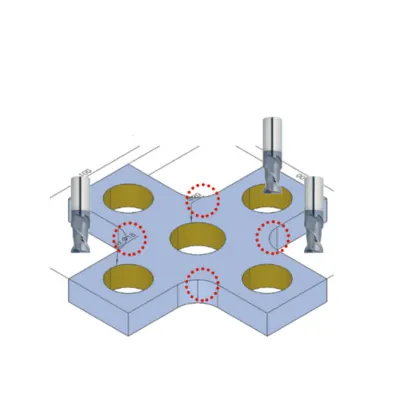

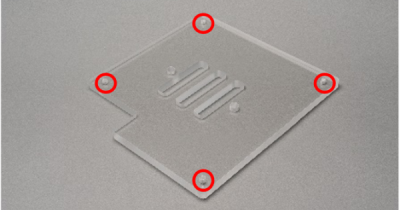

Reducing the Number of Machined Surfaces by Adding a Corner Radius

By reducing the number of machined surfaces, setup time can be minimized, which allows for cost reduction.

There are several ways to decrease the number of surfaces where the end mill operates. For example, in the part shown below, we increased the corner radius to achieve this.

When quoting with meviy,

Days to ship: 8 days

Cost per unit: $109.94 to $65.09 *

Check the price differences using our sample models: meviy-samples-cross

* The prices are as of the end of November 2024.

For the latest pricing, please download the 3D models above and check them on meviy.

Conclusion

Implementing smart design tips can significantly reduce the cost of custom computer numerical control (CNC)-milled parts. By carefully selecting an end mill with a larger diameter and strategically reducing the number of machined surfaces, you can optimize the machining process, leading to a reduction in final costs by about 50%.

As manufacturers and engineers, we understand the importance of balancing quality and cost-effectiveness. By integrating these smart design tips into your projects, you can achieve optimal results without compromising the integrity of the final product.

What’s meviy?

On-demand, fast sourcing of quality custom mechanical parts is made possible by meviy.

meviy is one of the most reliable on-demand manufacturing platforms in the US that allows you to get instant quotes for your mechanical parts simply by uploading 3D CAD data. No longer need to create 2D drawings just to quote parts. This platform supports not only manufacturing but also common surface finishes for sheet metal fabrication and CNC machining, including milling and turning, and has saved time for over 160,000 mechanical designers and purchasers worldwide.