Polycarbonate: Characteristics, Uses, and All About It

Polycarbonate (PC) is a highly transparent and durable plastic material celebrated for its extensive use in both industrial and everyday applications. But what exactly is the plastic, and what makes it such a standout among plastic materials? In this article, we explore the characteristics and uses of polycarbonate, as well as how it compares to acrylic, another popular transparent resin and plastic.

Table of Contents

What is Polycarbonate?

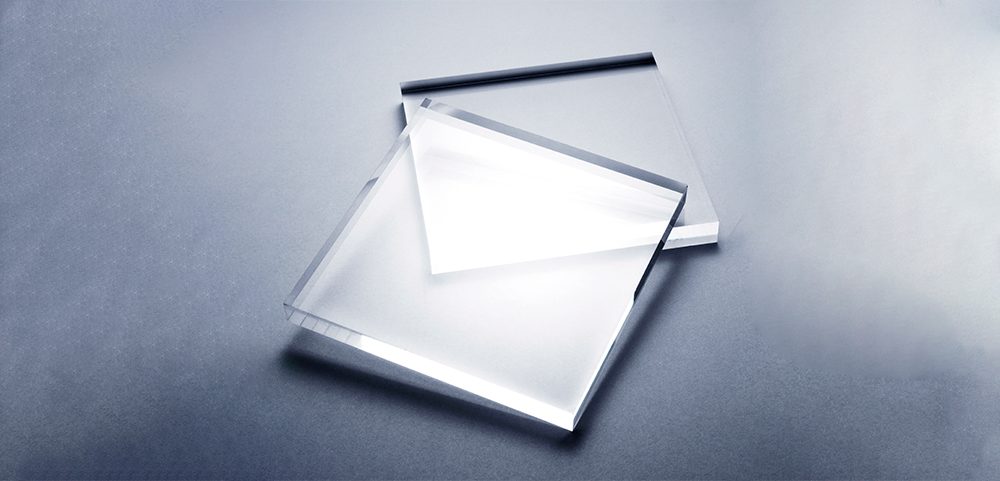

Polycarbonate is a type of thermoplastic rplastic that’s classified as an engineering plastic due to its impressive properties. It’s known for its exceptional transparency and impact resistance. Often abbreviated as PC, this material is sometimes called “organic glass.” Its versatility makes it a go-to choice for a wide array of products, including optical devices like camera lenses and car headlights, home decor items such as room dividers and aquariums, and even in the manufacture of bullet-resistant materials.

Advantages of Polycarbonate

The unique blend of high transparency and impact resistance distinguishes polycarbonate. Its resistance to UV light and moisture, stable dimensions, and versatile processing capabilities are additional benefits.

High Transparency

Polycarbonate is among the clearest plastics available, even rivaling the transparency of glass.

High Impact Resistance

It outperforms other clear plastics by a factor of 50 and is even 200 times more impact-resistant than glass.

High Weather Resistance

Its impact resistance makes polycarbonate a robust option for outdoor use.

Low Water Absorption

With minimal water absorption, polycarbonate is less prone to size changes due to moisture.

Excellent Machinability

Its ease of processing allows for a broad spectrum of manufacturing such as molding and machining.

High Self-Extinguishing

Polycarbonate is hard to ignite and doesn’t promote flame spread, making it ideal for housing electrical equipment.

Disadvantages of Polycarbonate

Despite its many strengths, polycarbonate has some limitations:

Sensitivity to Organic Solvents

Polycarbonate can be damaged by certain chemicals, especially organic solvents and surfactants, which can cause it to crack and distort under stress. This is called Stress Corrosion Cracking (SCC).

Susceptibility to Scratches

Polycarbonate’s surface is softer than some materials, making it prone to scratches that can affect its transparency and appearance. It must be handled with care to avoid damage.

Relatively High Cost

Polycarbonate is generally more expensive than many other resins and plastics, which may limit its use in cost-sensitive applications.

Polycarbonate vs. Acrylic

Acrylic (PMMA) is also a highly transparent plastic like polycarbonate. While acrylic offers slightly better transparency, there are key differences to note:

Impact Resistance

Polycarbonate has a significantly higher impact resistance than acrylic, about 50 times more, making it the preferred choice for high-risk applications like bullet-resistant materials.

Processability

Both materials are highly workable, but polycarbonate may present more challenges in bending and bonding compared to acrylic.

Flame Resistance

Polycarbonate is less likely to catch fire, with better self-extinguishing properties and a higher tolerance for continuous heat, making it more suitable for applications like safety barriers.

Cost

Acrylic is more budget friendly. Given polycarbonate’s higher price tag, alternative materials like acrylic may be considered for mass-production or less demanding products.

These differences are crucial when selecting both plastics for specific uses.

Conclusion

Polycarbonate (PC), an engineering thermoplastic , is renowned for its exceptional transparency and unmatched impact resistance. It boasts several advantages including high weather resistance, ease of machining, self-extinguishing properties, and minimal water absorption, which contribute to its precise dimensional stability. However, it is sensitive to certain chemicals that cause environmental stress cracking, is prone to scratching, and tends to be more costly. PC is used in a variety of products from camera lenses and car headlights to signs and protective materials. While acrylic shares some similarities, PC leads in terms of impact and flame resistance, whereas acrylic is more processable and cost-effective.

What’s meviy?

On-demand, fast sourcing of quality custom mechanical parts is made possible by meviy.

meviy is one of the most reliable on-demand manufacturing platforms in the US that allows you to get instant quotes for your mechanical parts simply by uploading 3D CAD data. No longer need to create 2D drawings just to quote parts. This platform supports sheet metal fabrication and CNC machining such as milling or turning and has saved time for over 160,000 mechanical designers and purchasers worldwide.