The Benefits of Nut Mounting: Maximizing Design Efficiency

Nut mounting, a widely used method in mechanical parts assembly, plays a crucial role in securing components together. By utilizing nuts as fasteners, engineers can achieve enhanced stability, ease of assembly, and increased versatility in their designs. Whether joining two parts, securing panels, or providing adjustable connections, nut mounting offers a reliable and efficient solution that has become indispensable in many industries.

Table of Contents

In this blog, we dive deeper into the specific benefits of nut mounting, exploring its impact on design efficiency, mechanical performance, and overall cost-effectiveness. So, let’s tighten our bolts and explore the world of mounted nut benefits available to engineers!

Enhancing Mechanical Integrity with Nut Mounting

Engineers understand the importance of precise and secure fastening in mechanical systems. Nut mounting offers an effective solution for ensuring the integrity and functionality of designs. Capable of handling a wide range of loads and vibrations, nuts provide a reliable connection method that prevents unwanted loosening and enhances the longevity of mechanical assemblies. Moreover, the flexibility offered by mounted nuts enables engineers to adjust, easily disassemble, and reassemble components, saving valuable time during the prototyping, production, and maintenance stages.

Not only does nut mounting provide practical benefits, it also offers design freedom. Engineers can explore various configurations and easily incorporate nuts into their designs. This allows for efficient assembly, disassembly, and potential future modifications.

Major Benefits of Nut Mounting

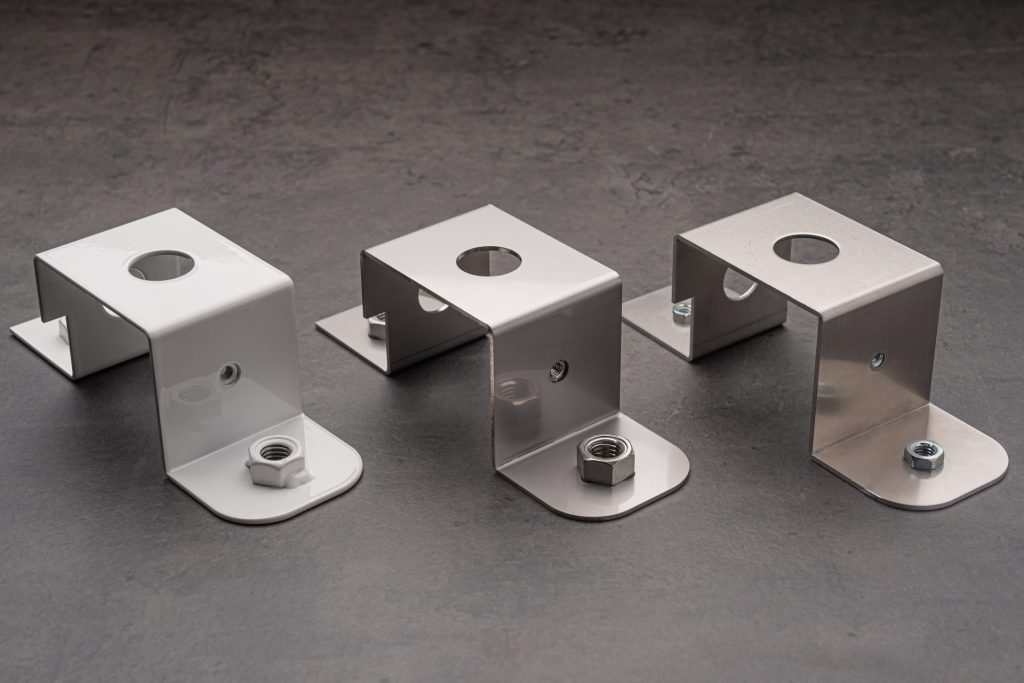

Stronger Stability

When fastening sheet metal parts, it’s common to use drill-tapped holes and secure them with bolts. However, thin materials can make it challenging to create large-diameter tapped holes. Nut mounting enables the use of larger-diameter bolts without needing to change the thickness of the sheet metal.

This improves the overall strength and stability of the assembly, ensuring a secure and robust connection. This is especially important in applications subjected to high levels of vibration, load, or stress.

Ease of Maintenance

By using nuts to secure mechanical components, it remains easy to remove and detach them when necessary. This feature greatly simplifies maintenance, repairs, and adjustments, as components can be easily accessed and replaced without causing damage. Whether it’s replacing worn-out parts or fine-tuning the assembly, the convenience of disassembling nut-mounted components ensures efficient and trouble-free operations, saving valuable time and effort.

Weight Reduction

Nut mounting can also reduce the overall weight of mechanical components. Compared to alternative methods that require thicker materials, it offers a more efficient solution that maintains structural integrity while minimizing weight. This lightweight advantage is particularly valuable in applications where weight reduction is crucial, such as in aerospace, automotive, or portable devices. The use of nut mounting allows engineers to achieve the optimal balance between strength and weight, resulting in enhanced performance and improved efficiency.

Conclusion

As we’ve seen in this article, the incredible benefits of mounted nuts make them one of the most versatile solutions for improving the strength and performance of sheet metal parts.

meviy Sheet Metal:

How to Set Nut Mounting

With meviy, obtaining custom sheet metal parts with mounted nuts has never been easier. Let’s take a look at how to do it!

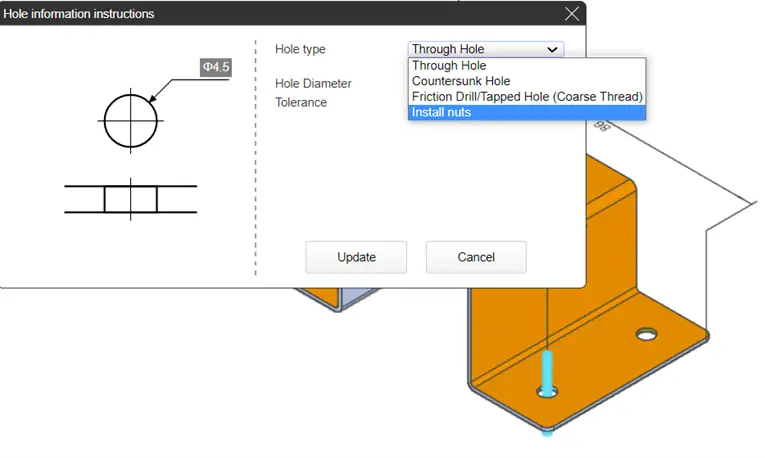

- First, upload your 3D model of the custom sheet metal part, then double-click on the hole where you’d like the nut mounting. This will open a pop-up with instructions for the hole information. Here, you can change the hole type by clicking on the drop-down menu and selecting “Install Nuts” to add the nuts.

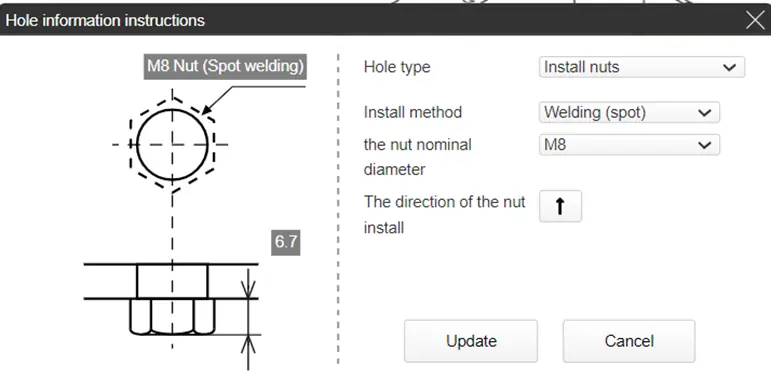

You can choose from three different nut mounting methods: press-fit, spot weld, or arc weld.

However, you can select only one method for each specific part.

- After choosing “Install Nuts,” you can now finalize all the remaining details by selecting your preferred installation method, the nut’s diameter, and lastly, the direction of the nut. To save all your changes, simply click the “Update” button.

Now, you can easily procure your custom sheet metal parts with mounted nuts directly through meviy!

For more details on nut mounting, please also refer to “Quality Control of Nut Mounted Products” and “Selectable Nut Sizes.”