What is 2017 Aluminum?

Material Overview and Design Considerations

Aluminum used in industrial settings often takes the form of an alloy, with various types available. One precious alloy is aluminum 2017, also known as duralumin, which is known for its strength, workability, and lightweight properties. But what is it exactly, and what makes it so unique? In this article, we delve into an overview of duralumin’s characteristics and examine how it sets itself apart from similar materials.

Table of Contents

What is Aluminum 2017?

Duralumin (aluminum 2017) is an aluminum alloy blended with copper (ranging from 3.5%–4.5%) and magnesium (0.40%–0.80%). Pure aluminum is notably lightweight and soft with low strength, and it has a hardness of around 65HB. With the added copper content in aluminum 2017, its hardness is boosted up to 105HB. In certain applications, aluminum 2017 can achieve strength levels comparable to those of steel materials.

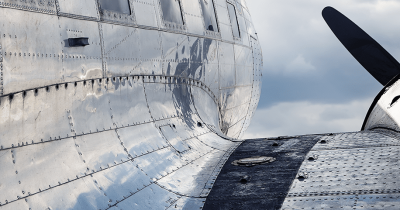

Aluminum 2017 is distinguished by its lightweight properties, strength, and ease of processing. Consequently, it is extensively used in aircraft and mechanical components, among other uses. Additionally, its machinability is significantly enhanced with magnesium content, making it ideal for cutting and forging processes.

Advantages of Aluminum 2017

Lightweight

Lighter weight compared to carbon steel and similar materials. With a specific gravity of 2.79, A2017 is much lighter than carbon steel (which has a specific gravity of 7.8).

Strong

Higher strength compared to other aluminum materials. Copper strengthens the alloy, giving it approximately 1.6 times the strength of pure aluminum.

Good Machinability

The magnesium content makes A2017 easy to cut, shape, and forge.

Disadvantages of Aluminum 2017

Poor Weldability

Generally, aluminum is challenging to weld due to oxide film formation and high thermal conductivity. Aluminum 2017 inherits this trait, showing poor weldability. Issues include the necessity to remove the oxide film beforehand, which melts at a higher temperature than the base material, and the risk of unstable fusion due to rapid heat dissipation from the base material.

Reduced Corrosion Resistance

The inclusion of copper decreases aluminum 2017’s corrosion resistance compared to pure aluminum. In corrosion-prone environments, protective measures are crucial. Unlike general-purpose aluminum or pure aluminum, aluminum 2017 poses challenges for anodizing treatments, so careful consideration is required when looking into anodizing for corrosion protection.

Aluminum 2017 Applications

Aluminum 2017 is used in many applications due to its lightweight properties and high strength. Typical examples include:

- Aircraft and rocket components

- Materials for ships

- Mechanical parts such as hydraulic systems and gears

- The attached cases

- Fasteners such as screws and rivets

- Window frames for houses

- Frames for tents and outdoor chairs

Aluminum 2017 was once a material used for airship frames and subsequently for aircrafts and other applications. The demand for the material grew significantly, especially for use in fighter planes. Today, it is used not only in airplanes but also in everyday life, such as for window frames and attached cases.

Duralumin Variants

In the duralumin family, there are other aluminum alloy materials, including aluminum 2024 and aluminum 7075. While their densities are similar to aluminum 2017 (ranging from 2.79–2.8), their strengths and properties vary.

- Aluminum 2024 (Super Duralumin): This is stronger than aluminum 2017 due to its higher copper and magnesium levels, but it has even lower corrosion resistance.

- Aluminum 7075: This is the strongest duralumin, which contains zinc in addition to copper and magnesium. The hardness makes it more difficult to machine, and it is prone to stress corrosion cracking.

Differences from Stainless Steel and Iron

Specific gravity (the ratio of the density of a substance to the density of a standard) is the biggest difference between aluminum 2017 and other materials such as stainless steel and iron. Aluminum 2017 is far lighter than steel or iron, with less than half the weight, making it ideal for applications where weight reduction is critical. However, stainless steel and iron are generally stronger and easier to weld.

Conclusion

Duralumin, or simply aluminum 2017, is an aluminum alloy incorporating copper and magnesium, which results in a material that is both lightweight and strong. Its exceptional qualities make it suitable for a wide range of applications, including aircraft components, ships, and fastening devices such as screws and rivets. While aluminum 2017 offers excellent workability and durability, it lacks in corrosion resistance and strength when compared to materials such as steel. It is part of the duralumin family, which includes variants such as super duralumin and others. These variants offer even greater strength than aluminum 2017.

What’s meviy?

On-demand, fast sourcing of quality custom mechanical parts is made possible by meviy.

meviy is one of the most reliable on-demand manufacturing platforms in the US that allows you to get instant quotes for your mechanical parts simply by uploading 3D CAD data. No longer need to create 2D drawings just to quote parts. This platform supports sheet metal fabrication and CNC machining such as milling or turning and has saved time for over 160,000 mechanical designers and purchasers worldwide.