ISO Tapered Threads Now Supported in CNC Turning

Last Updated: May 20, 2025

New Feature: ISO Tapered Thread Support for CNC Turning (R & Rc, Sizes 1/16″–1 1/2″) Now Available

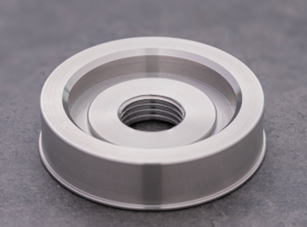

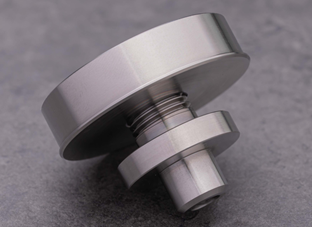

meviy has expanded its CNC turning capabilities to include automatic quoting for ISO Tapered Threads, supporting both internal (Rc) and external (R) thread types.

This enhancement allows users to design pressure-tight threaded connections directly into their turned parts.

Benefits to Users

- Enables precise design of components requiring sealed or pressure-tight connections

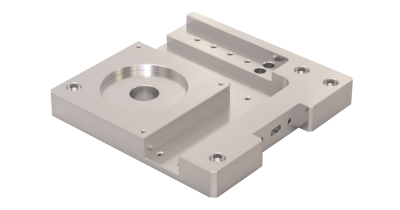

- Streamlines manufacturing of pipes, fittings, and fluid-handling components

- Reduces time-to-quote by supporting automatic recognition of ISO tapered threads

- Increases flexibility in part design and reduces manual intervention in the quoting workflow

New Capabilities

Supported Thread Types:

- External Threads (R)

- Internal Threads (Rc)

Thread Size Range:

- 1/16″ to 1 1/2″ (per ISO standards)

Material Compatibility:

- Available across all current CNC turning materials offered on meviy

Design Requirements:

- Taper must be modeled into the 3D CAD file

- Threads must be aligned on the center axis of the part

Quoting Details & Requirements

- Standard ISO Thread Depths: Automatically quoted via meviy’s digital platform

- Non-standard/Custom Thread Depths: May require manual quoting

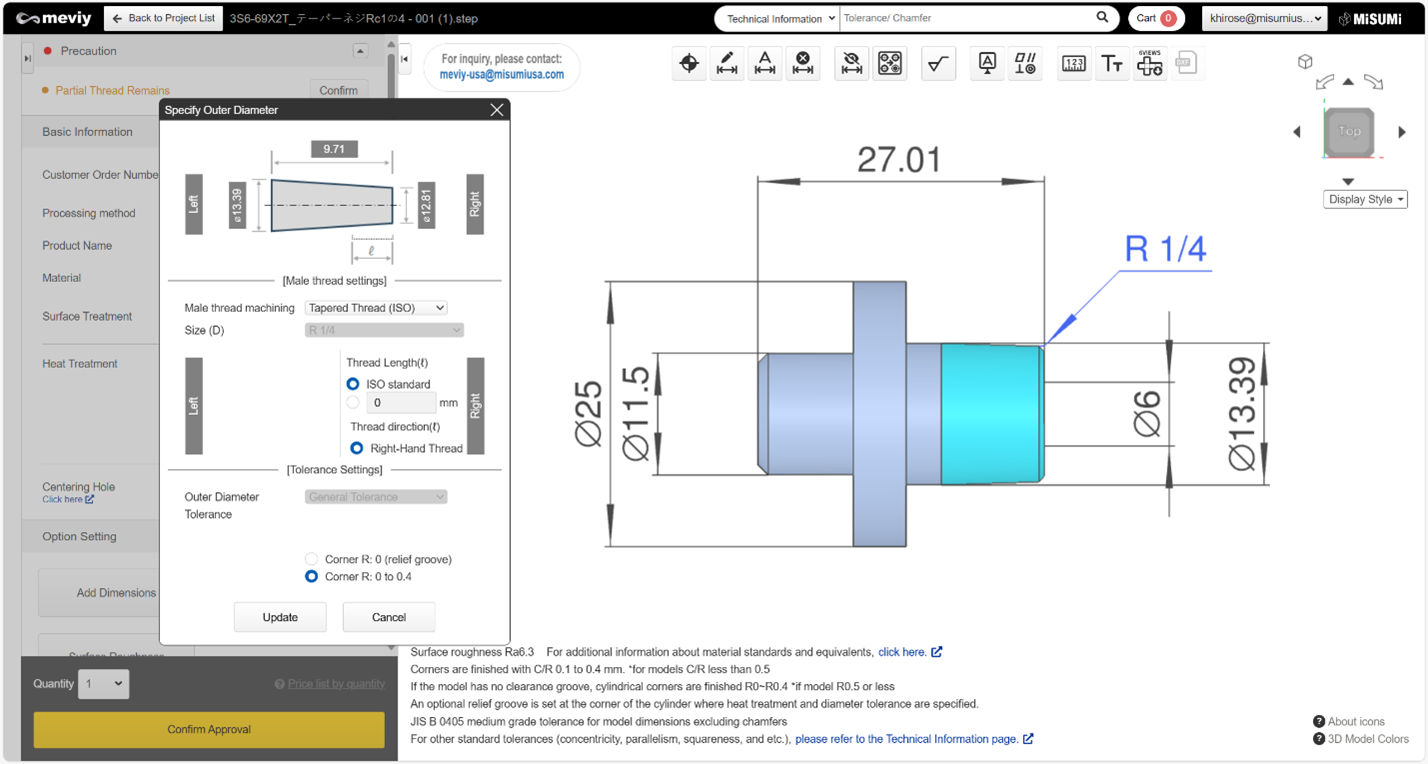

Tapered thread Setting

To specify a Tapered thread:

- Double click the taper on the OD or ID of the part

- Select “Tapered Thread (ISO)” from the drop down menu

- Select ISO standard depth for an Auto Quote or enter a depth for a Manual Quote.

This feature is live and available immediately on the meviy platform. Upload your CNC turning part with ISO tapered threads today at https://meviy.misumi-ec.com/en_us-us/

Please note:

- Only ISO tapered thread types (R/Rc) are currently supported; other standards (e.g., NPT, BSPT) are not included in this release.

- Ensure 3D CAD files accurately represent taper geometry and placement to receive an auto quote. The threads themselves should not be modeled into the part.