CNC Milling:

New Materials and Surface Finishes Now Available!

Take Note of Resins like PP, PPS, and PET

| Four new resin materials will soon be available for CNC milling, starting December 9, 2024. Stay ahead with the latest information by exploring the use cases for each of the following! | ▶ MC Nylon (conductive, black) ▶ PP (standard, white) ▶ PPS (standard, natural color) ▶ PET (glass-filled, brown) |

meviy’s CNC Milling service will introduce new annealed stainless steels and three types of surface treatments. Custom machined parts requiring surface finishes, such as low temperature black chrome, hard anodizing, and phosphate coating, can be efficiently processed from milling to surface treatment all in one place via meviy. Additionally, meviy offers AI-powered instant quoting for gold and red anodizing, which was previously limited to manual quotes. Now, you can quickly obtain pricing and delivery times for your custom parts with finishes.

Available Materials and Surface Treatments

| Carbon Steel | Aluminum Alloy | Stainless Steel | Resin |

Carbon Steel

| Material | Surface Treatment | Standard Shipping | Economy Shipping |

| 1018 Carbon Steel | No Treatment | 8 days | 22 days |

| Black Oxide | 10 days | ||

| Electroless Nickel | |||

| Trivalent Chromate (Clear) | |||

| Trivalent Chromate (Black) | |||

| Hard Chrome Plating (Flash Plating) | |||

| Low Temperature Black Chrome [NEW] | |||

| Phosphate coating [NEW] | |||

| 1018 Carbon Steel (Polished) | No Treatment | 8 days | 22 days |

| Black Oxide | 10 days | ||

| Electroless Nickel | |||

| 1018 Carbon Steel (Annealed) | No Treatment | 11 days | 25 days |

| Black Oxide | 13 days | 27 days | |

| Electroless Nickel | |||

| Trivalent Chromate (Clear) | |||

| 1045 Carbon Steel (Polished) | No Treatment | 8 days | 22 days |

| Black Oxide | 10 days | ||

| Electroless Nickel | |||

| 1049 Carbon Steel (equivalent) | No Treatment | 8 days | 22 days |

| Black Oxide | 10 days | ||

| Electroless Nickel | |||

| Trivalent Chromate (Clear) | |||

| Trivalent Chromate (Black) | |||

| Hard Chrome Plating (Flash Plating) | |||

| Low Temperature Black Chrome [NEW] | |||

| Phosphate coating [NEW] | |||

| 1049 Carbon Steel (equivalent) (Tempered) | No Treatment | 11 days | 25 days |

| Black Oxide | 13 days | 27 days | |

| Electroless Nickel | |||

| Hard Chrome Plating (Flash Plating) | |||

| Trivalent Chromate (Clear) | |||

| Trivalent Chromate (Black) | |||

| Low Temperature Black Chrome [NEW] | |||

| Phosphate Coating [NEW] | |||

| NAK55 or equivalent | No Treatment | 8 days | 22 days |

| 4140 Alloy Steel | No Treatment | 8 days | 22 days |

| Black Oxide | 10 days | ||

| Electroless Nickel | |||

| Trivalent Chromate (Clear) |

Aluminum Alloy

| Material | Surface Treatment | Standard Shipping | Economy Shipping |

| 2017 Aluminum Alloy | No Treatment | 8 days | 22 days |

| Clear Anodize | 10 days | 22 days | |

| Black Anodize | |||

| Black Anodize (Matte) | |||

| Red Anodize | |||

| Gold Anodize | |||

| Hard Anodize (Clear) [NEW] | |||

| 5052 Aluminum Alloy | No Treatment | 8 days | 22 days |

| Clear Anodize | 10 days | 22 days | |

| Black Anodize | |||

| Black Anodize (Matte) | |||

| Red Anodize | |||

| Gold Anodize | |||

| Hard Anodize (Clear) [NEW] | |||

| 6061 Aluminum Alloy | No Treatment | 8 days | 22 days |

| Clear Anodize | 10 days | 22 days | |

| Black Anodize | |||

| Black Anodize (Matte) | |||

| Red Anodize | |||

| Gold Anodize | |||

| Hard Anodize (Clear) [NEW] | |||

| 6063S Aluminum Alloy | No Treatment | 8 days | 22 days |

| Clear Anodize | 10 days | ||

| Black Anodize | |||

| 7075 Aluminum Alloy | No Treatment | 8 days | 22 days |

| Clear Anodize | 10 days | 22 days | |

| Black Anodize | |||

| Black Anodize (Matte) | |||

| Red Anodize | |||

| Gold Anodize | |||

| Hard Anodize (Clear) [NEW] |

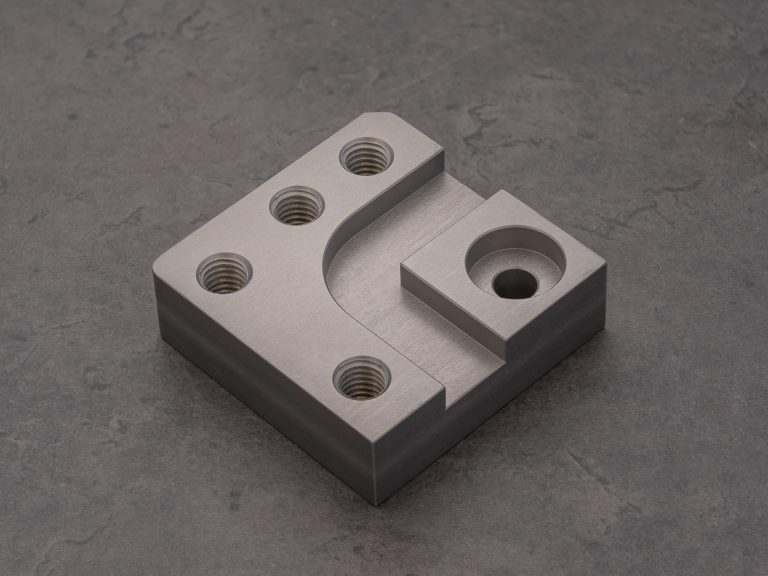

Stainless Steel

| Material | Surface Treatment | Standard Shipping | Economy Shipping |

| 303 Stainless Steel | No Treatment | 8 days | 22 days |

| 303 Stainless Steel (Annealed) [NEW] | No Treatment | 8 days | 22 days |

| 304 Stainless Steel | No Treatment | 8 days | 22 days |

| 304 Stainless Steel (Annealed) [NEW] | No Treatment | 8 days | 22 days |

| 304 Stainless Steel (Polished) | No Treatment | 8 days | 22 days |

| 316 Stainless Steel | No Treatment | 12 days | 26 days |

| 430 Stainless Steel | No Treatment |

Resin

| Material | Standard Shipping | Economy Shipping | |

| Acetal | Standard, White | 8 days | 22 days |

| Standard, Black | |||

| MC Nylon | Standard, Blue | 8 days | 22 days |

| Standard, Ivory | |||

| Conductivity, Black [NEW] | |||

| Weather Resistance, Black Ash | |||

| Polypropylene (PP) | Standard, White [NEW] | 8 days | 22 days |

| Polyphenylene Sulfide (PPS) | Standard, Natural Color [NEW] | 8 days | 22 days |

| polyethylene Terephthalate (PET) | Glass Filled, Brown [NEW] | 8 days | 22 days |

| Bakelite | Paper, Natural Color | 8 days | 22 days |

| Paper, Black | |||

| Cloth, Natural Color | |||

| Polytetrafluoroethylene (PTFE) | Standard, White | 8 days | 22 days |

| UHMWPE | Standard, White | 8 days | 22 days |

| Conductivity, Black | |||

| ABS | Standard, Natural Color | 8 days | 22 days |

| PEEK | Standard, Gray-brown | 8 days | 22 days |

Use Cases

303 Stainless Steel (Annealed)

304 Stainless Steel (Annealed)

Hard Anodize

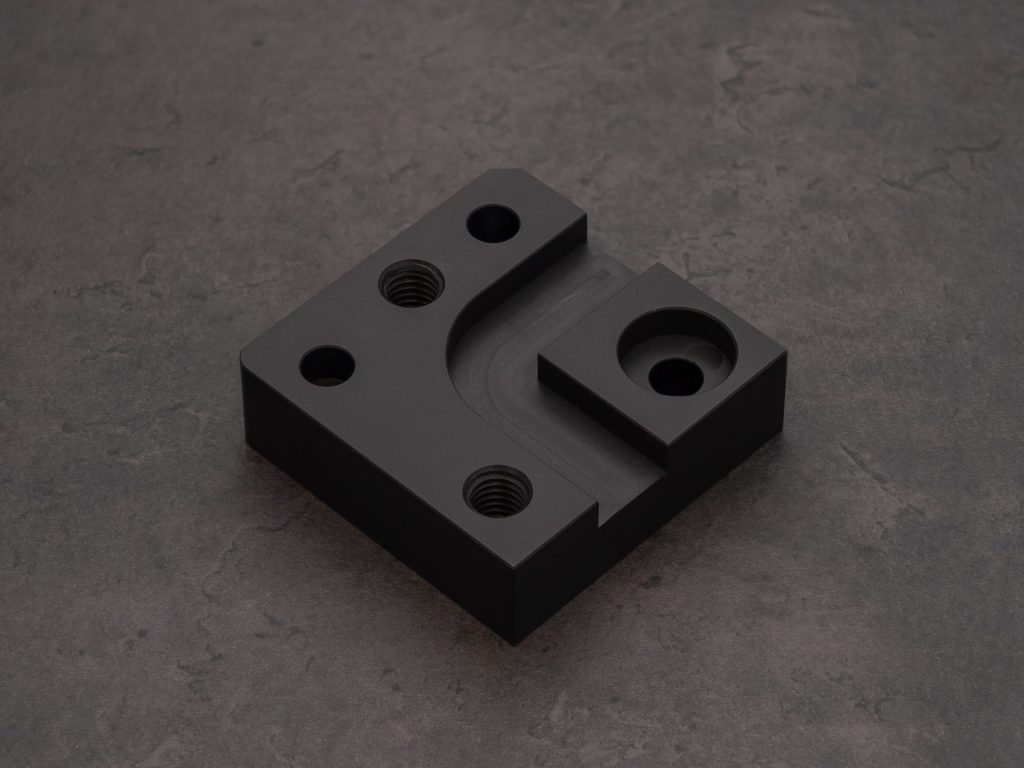

Phosphate Coating

Low Temperature Black Chrome Plating

MC Nylon

(Conductivity, Black)

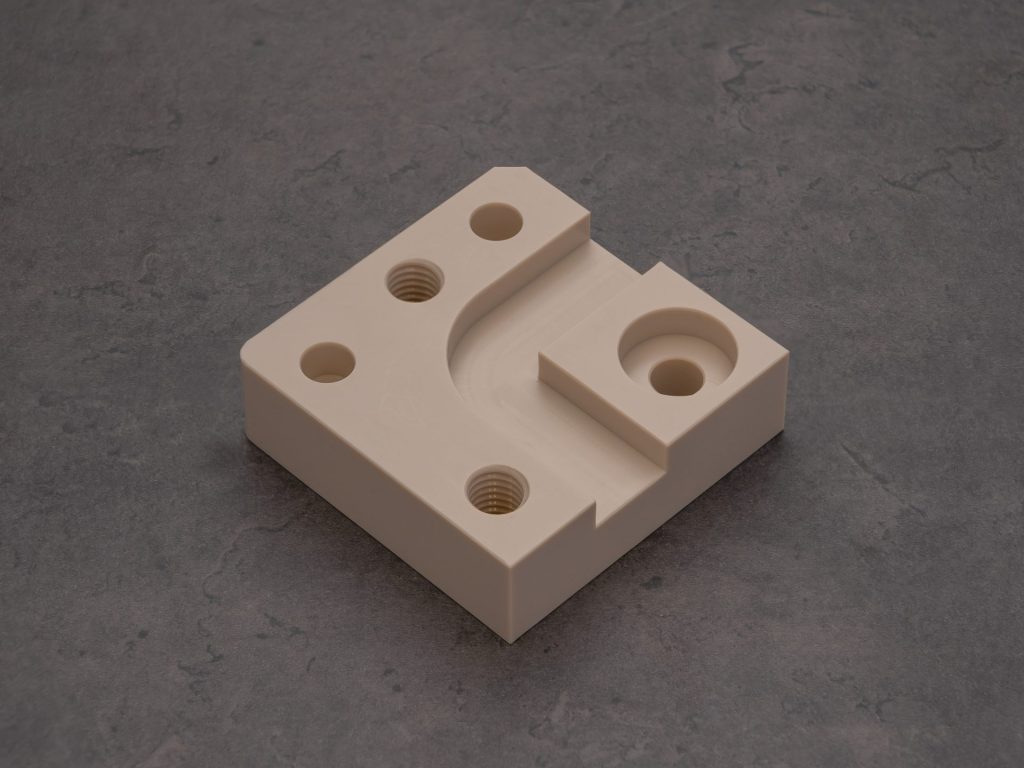

PP

(Standard, White)

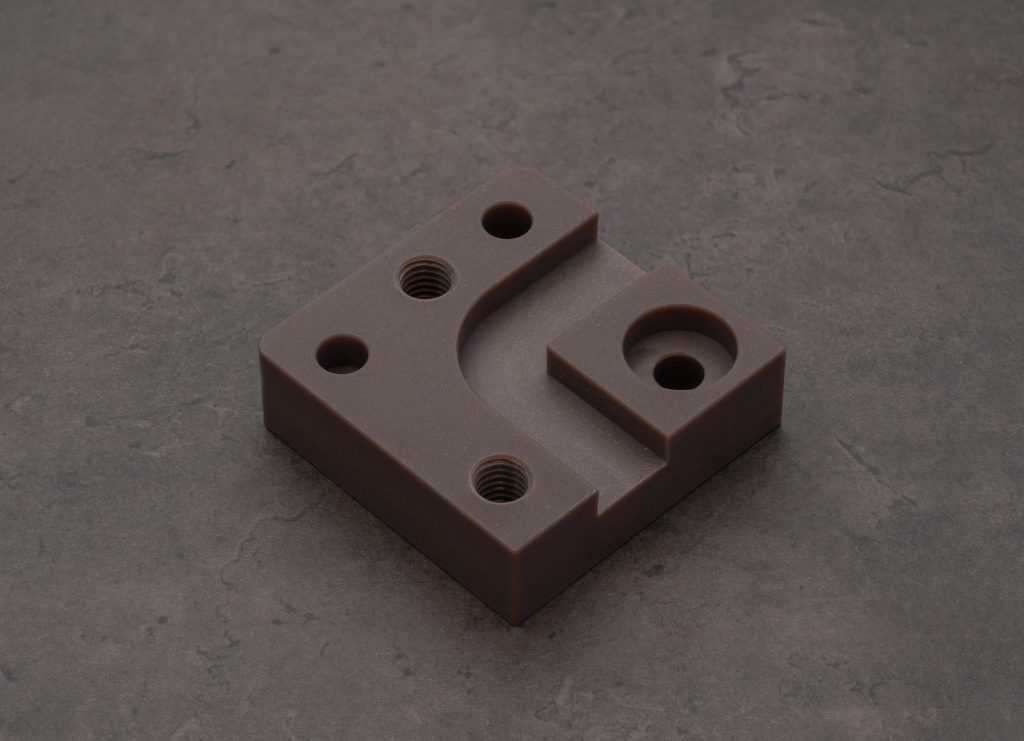

PET

(Glass Filled, Brown)

PPS

(Standard, Natural Color)

-

What is Annealing?

Also known as “normalizing,” annealing is a heat treatment process used to soften materials and achieve uniform microstructure through slow cooling. This method effectively removes residual stresses that can cause warping or bending during machining.

303 Stainless Steel (annealed)

- Features

- Heat Treatment Process: Reheating to the crystallization temperature followed by slow cooling eliminates internal stresses and achieves material softening, resulting in enhanced ductility.

- Stability in Tolerances: Compared to standard materials, this process minimizes distortion, ensuring stable tolerances after machining.

- Machinability: Among stainless steels, this material offers superior machinability, making it ideal for complex designs.

- Applications

- Automotive equipment, chemical processing equipment, high-precision parts, household items, architectural elements

> See the difference between 303 and 304 stainless steel.

304 Stainless Steel (annealed)

- Features

- Heat Treatment Process: Reheating to the crystallization temperature followed by slow cooling eliminates internal stresses and achieves material softening, resulting in enhanced ductility.

- Stability in Tolerances: Compared to standard materials, this process minimizes distortion, ensuring stable tolerances after machining.

- Excellent Weldability: The annealed 304 stainless steel offers superior weldability, making it suitable for various applications.

- Applications

- Automotive equipment, chemical processing equipment, high-precision parts, household items, architectural elements

> See the difference between 303 and 304 stainless steel.

Hard Anodize

- Features

- Durable Coating: Aluminum treated with hard anodizing achieves a robust film that provides excellent wear resistance.

*The appearance may vary depending on the material and coating thickness.

- Durable Coating: Aluminum treated with hard anodizing achieves a robust film that provides excellent wear resistance.

- Applications

- Automotive equipment, railway systems, aerospace components, medical devices

Phosphate Coating

- Features

- Corrosion and Wear Resistance: Phosphate coating offers excellent protection against rust and wear.

- High Adhesion: Its strong adhesion makes it ideal for use as a pre-treatment before painting.

* The treatment uses either zinc phosphate or manganese phosphate, resulting in variations in color and appearance. Please note that the selection of the treatment solution is not available.

- Applications

- Automotive equipment, industrial machinery, robotics, parts prior to painting

Low Temperature Black Chrome Plating

- Features

- Corrosion Protection: This surface treatment provides excellent rust and Long-lasting corrosion resistance.

- Uniform Thin Coating: With a film thickness of approximately 2μm, it allows for high machining precision, even on treated surfaces.

- Matte Black Finish: The matte black color helps prevent glare and reflection.

- Applications

- Semiconductor equipment, medical devices, optical instruments, architectural elements

MC Nylon (conductivity, black)

- Features

- Strength and Heat Resistance: Combines the strength and heat resistance characteristic of MC Nylon.

- Conductivity and Anti-static: This grade nylon retains excellent conductivity and anti-static properties.

- Applications

- Components for electronic devices, insulation parts for electrical equipment

PP (Polypropylene)

- Features

- Heat and Chemical Resistance: PP is a white plastic with excellent heat and chemical resistance.

- Cost-effectiveness: Lightweight and reasonable, making it a versatile and widely used general-purpose plastic.

- Applications

- Home appliances, automotive parts, packaging materials, consumables

PET (glass filled, brown)

- Features

- Low Water Absorption: This resin, called Unilate, is made from polyethylene terephthalate (PET) with glass fibers and inorganic fillers, offering low moisture absorption.

- High Dimensional Stability: It offers excellent dimensional stability.

- Machinability: Good machinability properties.

- Electrical Insulation: Like other resins, this resin possesses electrical insulation properties.

- Applications

- Electrical insulation materials, semiconductor manufacturing equipment, electronic components (especially insulation parts)

PPS (standard, natural color)

- Features

- High Heat, Wear, and Chemical Resistance: PPS offers excellent resistance to heat, wear, and chemicals.

- Electrical Insulation: PPS, a type of super engineer plastics, provides excellent electrical insulation properties.

- High Dimensional Stability: Maintains dimensional stability even under harsh conditions.

- Cost-effective: This resin is more affordable than PEEK (about 3-4 times cheaper), a similar engineering plastic.

- Applications

- Automotive parts (e.g., engine components), electronic device parts, precision machinery, medical devices, high-temperature parts