Sheet Metal

Explore 5 New Wet Paint Colors!

Effective September 1, 2024, Wet Paint parts have been added to meviy’s Sheet Metal. This option is ideal for visually indicating hazardous areas in your plant or procuring brightly colored parts.

Wet Paint Color Options

With the introduction of Wet Paint, you can now choose from 5 new colors, as highlighted below:

| Material | Paint Color | Thickness (mm) |

Shipping Days (as soon as) |

||

|---|---|---|---|---|---|

| Color Swatch | Munsell Value RAL Color (approx.) |

||||

|

Cold/Hot Rolled Steel |

|

Red

5R4/14 |

0.8 1.0 1.2 1.6 2.0 2.3 3.2 4.5 6.0 | 8 days | |

|

|

Smoke Blue

10B6/7 |

||||

|

|

Moss Green

7.5GY8/3 RAL 1000 |

||||

|

|

Deep Orange

2.5YR6.5/13 RAL 2011 |

||||

|

|

Light Brown

5Y8.25/1.5 RAL 7032 |

||||

Manufacturing Examples with Wet Paint

Material Cold/Hot Rolled Steel Thickness 1.6 mm Size 121 × 100 × 40 mm Standard Shipping as soon as 8 days -

Material Cold/Hot Rolled Steel Thickness 3.2 mm Size 126 × 110 × 40 mm Standard Shipping as soon as 8 days

About Painted Sheet Metal Parts

-

Quality

Quality check methods include a film thickness gauge, tape to check adhesion, and a cross-cut sample test.

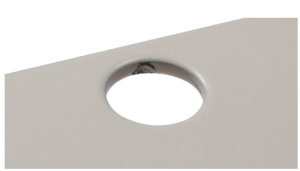

The appearance is visually checked for color, dust, spots, dimples, etc. by referring to a defect size estimation chart. Screws are used to check the functionality of tapped holes.  * The hanging jig used during the painting process may leave some scratches and marks; see the photo above.

* The hanging jig used during the painting process may leave some scratches and marks; see the photo above.

Comparison with Powder Coating

The main quality standards for Powder Coat and Wet Paint are shown in the table below. The values are approximate values.

| Powder Coat | Wet Paint | |

|---|---|---|

| Film thickness *1 | 80±30μm | 30±15μm |

| Baking temperature | 180°C | 140°C |

| Baking time | 20 to 30 min | 20 to 30 min |

| Salt spray test *2 | 120 hours | 72 hours |

*1 Not a guaranteed value as the film thickness may vary depending on the shape.

*2 Based on JIS Z2371 salt spray test method

(Powder: 60±5μm after baking at 180℃ for 20 minutes, Wet paint: 25±5μm after baking at 100℃ for 20 minutes)