CNC Turning:

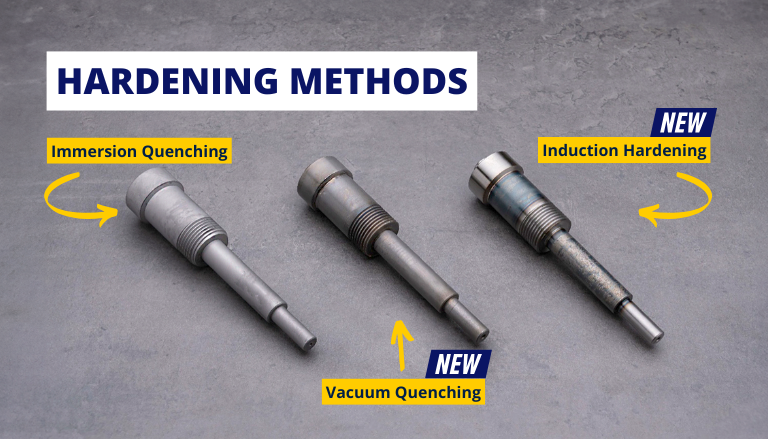

New Hardening Methods

Expanded Hardening Methods for Heat Treatment

We now offer two additional options, bringing the total to three hardening methods. These methods are designed to meet a wide range of heat treatment requirements, providing greater flexibility and precision for various applications.

Full Part Hardening

For full part hardening, you can choose from two options for heat treating and quenching the entire part to achieve the desired hardness specification:

- Immersion Quenching

Immersion Quenching is a method of heat treatment using a conventional furnace and oil bath quenching that is quick and cost effective. - Vacuum Quenching NEW

Vacuum Quenching is a method of heat treatment using a vacuum furnace and gradual quenching that is less likely to distort the finished part but takes longer.

Selective Hardening

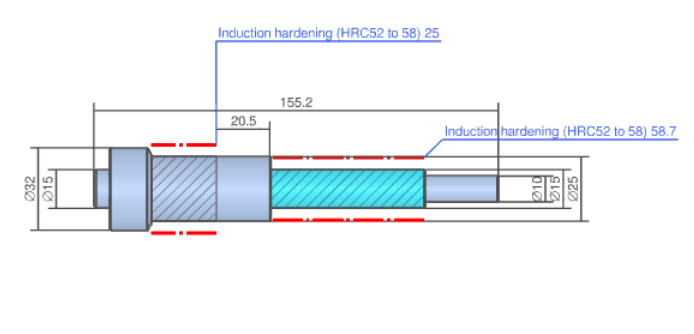

Selective hardening allows you to specify specific areas for hardening, targeting only those regions that require it while excluding areas with threads or precision tolerances.

- Induction Hardening NEW

Induction Hardening is a method of heat treatment that heats and quenches only a specific area of a part using an induction coil.

Material Hardness Range

In addition, meviy now can specify a desired hardness range for both Immersion Quenching and Vacuum Quenching services.

| Material | Full Part Hardening | Selective Hardening | ||||

| Immersion Quenching | Vacuum Quenching | Induction Hardening | ||||

| Standard Hardness (HRC) | Selectable Hardness (HRC) | Standard Hardness (HRC) | Selectable Hardness (HRC) | Standard Hardness (HRC) | Selectable Hardness (HRC) | |

| 1045 Carbon Steel | 40 – 45 | 30 – 45 | 40 – 45 | 30 – 45 | 52 – 58 | – |

| 4135 Alloy Steel | 35 – 40 | 30 – 45 | 35 – 40 | 30 – 45 | 52 – 58 | |

| 4140 Alloy Steel | 50 – 55 | 30 – 55 | 50 – 55 | 30 – 55 | 52 – 58 | |

| O1 Tool Steel | 58 – 63 | 40 – 63 | 58 – 63 | 40 – 63 | 58 – 63 | |

| SKD11 | 58 – 63 | 50 – 63 | 58 – 63 | 50 – 63 | – | |

| SKD61 | 50 – 55 | 40 – 55 | 50 – 55 | 40 – 55 | – | |

| SUJ2 | 58 – 63 | 35 – 63 | 58 – 63 | 35 – 63 | 57 – 63 | |

| 440C Stainless Steel | 58 – 63 | 45 – 63 | 58 – 63 | 45 – 63 | – | |

- The expansion of Heat Treatment capabilities has also expanded the maximum length of parts that can be hardened:

- 10-150mm (OD) : up to 300mm in length.

- 150-250mm (OD): up to 200mm in length.

- 250-300mm (OD): up to 100mm in length.

- The additional lead time for a hardened part is 2 to 4 days.

- The depth of hardness cannot be specified, but a depth of 1mm or more into the part surface is guaranteed.

Hardened Part Examples

Induction Hardening for Selective Hardening

1045 Carbon Steel with no surface treatment

- Appearance

- 3D view image

* Apply selective hardening to two locations.

References for Hardening

- Supported Hardness and Lead Times by Material: Lead Times

- Appearance and Quality Standards of Hardened Products: Appearance Quality

- Operation Manual on How to Specify Different Hardening Methods: Hardness Selection