- HELP

- Technical Information

- CNC Milling

- Accuracy and Machining Specifications

- Standards for Different Hole and Pocket Types

Standards for Different Hole and Pocket Types

Straight Holes

Holes that are machined with drills or end mills that do not have a specified precision are referred to as “straight holes” on the cutting service. Tools used for machining have different auto-quotable machining depths.

The maximum value is included as an approximation.

The maximum value may vary depending on other quoted conditions such as shape and material. Thank you for your understanding.

Drill Machining

[mm]

| Steel, Pre-Hardened Steel & Tool Steel, Aluminum, Stainless steel | |

|---|---|

| Diameter | Machining Depth (Approximate) |

| 1.0 ≤ Diameter ≤ 1.9 | 40 |

| 2.0 ≤ Diameter ≤ 3.2 | 150 |

| 3.3 ≤ Diameter ≤ 4.2 | 180 |

| 4.3 ≤ Diameter ≤ 6.9 | 200 |

| 7.0 ≤ Diameter ≤ 9.9 | 220 |

| 10 ≤ Diameter ≤ 20 | 300 |

[mm]

| Resin | |

|---|---|

| Diameter | Machining Depth (Approximate) |

| 1.0 ≤ Diameter ≤ 1.9 (Increments of 0.1) | ≤ Diameter * 10 |

| 2 | ≤ Diameter * 15 |

| 2.1 ≤ Diameter ≤ 3.0 (Increments of 0.1) | ≤ Diameter * 14 |

| 3.1 ≤ Diameter ≤ 4.2 (Increments of 0.1) | ≤ Diameter * 13 |

| 4.3 ≤ Diameter ≤ 5.7 (Increments of 0.1) | ≤ Diameter * 12 |

| 5.8 ≤ Diameter ≤ 6.8 (Increments of 0.1) | ≤ Diameter * 11 |

| 6.9 ≤ Diameter ≤ 9.7 (Increments of 0.1) | ≤ Diameter * 10 |

| 9.8 ≤ Diameter ≤ 13 (Increments of 0.1) | ≤ Diameter * 9 |

End Mill Machining

The machining depth of diameters without the drill is as follows:

[mm]

| Steel, Pre-Hardened Steel & Tool Steel | |||||

|---|---|---|---|---|---|

| Diameter | Machining Depth (Approximate) | Diameter | Machining Depth (Approximate) | ||

| > | ≤ | > | ≤ | ||

| 2.999 | 3.5 | ≤10 | 9 | 11 | ≤40 |

| 3.5 | 4.5 | ≤12 | 11 | 13 | ≤50 |

| 4.5 | 6 | ≤16 | 13 | 17 | ≤60 |

| 6 | 7 | ≤20 | 17 | 21 | ≤80 |

| 7 | 9 | ≤30 | 21 | No Restrictions | ≤100 |

[mm]

| Aluminum | |||||

|---|---|---|---|---|---|

| Diameter | Machining Depth (Approximate) | Diameter | Machining Depth (Approximate) | ||

| > | ≤ | > | ≤ | ||

| 2.999 | 3.5 | ≤10 | 9 | 11 | ≤40 |

| 3.5 | 4.5 | ≤12 | 11 | 13 | ≤50 |

| 4.5 | 6 | ≤16 | 13 | 17 | ≤60 |

| 6 | 7 | ≤25 | 17 | 21 | ≤80 |

| 7 | 9 | ≤30 | 21 | No Restrictions | ≤100 |

[mm]

| Stainless steel | |||||

|---|---|---|---|---|---|

| Diameter | Machining Depth (Approximate) | Diameter | Machining Depth (Approximate) | ||

| > | ≤ | > | ≤ | ||

| 2.999 | 3.5 | ≤10 | 9 | 11 | ≤32 |

| 3.5 | 4.5 | ≤12 | 11 | 13 | ≤40 |

| 4.5 | 6 | ≤16 | 13 | 17 | ≤48 |

| 6 | 7 | ≤20 | 17 | 21 | ≤64 |

| 7 | 9 | ≤24 | 21 | No Restrictions | ≤80 |

[mm]

| Resin | |||||

|---|---|---|---|---|---|

| Diameter | Machining Depth (Approximate) | Diameter | Machining Depth (Approximate) | ||

| > | ≤ | > | ≤ | ||

| 2.999 | 3.5 | ≤7.5 | 11 | 13 | ≤30 |

| 3.5 | 4.5 | ≤10 | 13 | 18 | ≤40 |

| 4.5 | 7 | ≤15 | 18 | No Restrictions | ≤60 |

| 7 | 11 | ≤20 | – | ||

[mm]

| |||||

|---|---|---|---|---|---|

| Diameter | Machining Depth (Approximate) | Diameter | Machining Depth (Approximate) | ||

| > | ≤ | > | ≤ | ||

| 2.999 | 3.5 | ≤14 | 9 | 11 | ≤34 |

| 3.5 | 4.5 | ≤17 | 11 | 13 | ≤44 |

| 4.5 | 6 | ≤19 | 13 | 17 | ≤54 |

| 6 | 7 | ≤22 | 17 | 21 | ≤64 |

| 7 | 9 | ≤24 | 21 | No Restrictions | ≤74 |

- Example: Drilling a straight hole with a diameter of 12.9 in Low Carbon Steel material

- The tool to be used is a drill and the machining depth is up to 200 mm.

- Example 2: Drilling a straight hole with a diameter of 13.1 in Low Carbon Steel material

- The tool to be used is an end mill and the machining depth is up to 48 mm.

Auto-Quotable Accuracy Ranges

A straight hole can be changed to a precision hole by setting the “Hole Diameter Tolerance Type.” By changing to a precision hole, the accuracy and effective depth for the diameter can be specified.

End Mill Machining

[mm]

| Diameter | Accuracy Ranges | |||

|---|---|---|---|---|

| > | ≤ | Fit Tolerance | Bidirectional Tolerance Minimum Value | Unidirectional Tolerance Minimum Value (Range) |

| – | 3 | Grade IT7 or higher | 0.005 | 0.01 |

| 3 | 6 | 0.006 | 0.012 | |

| 6 | 10 | 0.008 | 0.015 | |

| 10 | 18 | 0.009 | 0.018 | |

| 18 | 30 | 0.011 | 0.021 | |

| 30 | 50 | 0.013 | 0.025 | |

| 50 | 80 | 0.015 | 0.03 | |

| 80 | 120 | 0.018 | 0.035 | |

| 120 | 180 | 0.02 | 0.04 | |

| 180 | 250 | 0.023 | 0.046 | |

| 250 | 315 | 0.026 | 0.052 | |

| 315 | 400 | 0.029 | 0.057 | |

| 400 | 500 | 0.032 | 0.063 | |

Auto-Quotable Effective Depths

[mm]

| Steel, Pre-Hardened Steel & Tool Steel | |||||

|---|---|---|---|---|---|

| Diameter | Machining Depth (Approximate) | Diameter | Machining Depth (Approximate) | ||

| > | ≤ | > | ≤ | ||

| 2.999 | 3.5 | ≤10 | 9 | 11 | ≤40 |

| 3.5 | 4.5 | ≤12 | 11 | 13 | ≤50 |

| 4.5 | 6 | ≤16 | 13 | 17 | ≤60 |

| 6 | 7 | ≤20 | 17 | 21 | ≤80 |

| 7 | 9 | ≤30 | 21 | No Restrictions | ≤100 |

[mm]

| Aluminum | |||||

|---|---|---|---|---|---|

| Diameter | Machining Depth (Approximate) | Diameter | Machining Depth (Approximate) | ||

| > | ≤ | > | ≤ | ||

| 2.999 | 3.5 | ≤10 | 9 | 11 | ≤40 |

| 3.5 | 4.5 | ≤12 | 11 | 13 | ≤50 |

| 4.5 | 6 | ≤16 | 13 | 17 | ≤60 |

| 6 | 7 | ≤25 | 17 | 21 | ≤80 |

| 7 | 9 | ≤30 | 21 | No Restrictions | ≤100 |

[mm]

| Stainless steel | |||||

|---|---|---|---|---|---|

| Diameter | Machining Depth (Approximate) | Diameter | Machining Depth (Approximate) | ||

| > | ≤ | > | ≤ | ||

| 2.999 | 3.5 | ≤10 | 9 | 11 | ≤32 |

| 3.5 | 4.5 | ≤12 | 11 | 13 | ≤40 |

| 4.5 | 6 | ≤16 | 13 | 17 | ≤48 |

| 6 | 7 | ≤20 | 17 | 21 | ≤64 |

| 7 | 9 | ≤24 | 21 | No Restrictions | ≤80 |

[mm]

| Resin | |||||

|---|---|---|---|---|---|

| Diameter | Machining Depth (Approximate) | Diameter | Machining Depth (Approximate) | ||

| > | ≤ | > | ≤ | ||

| 2.999 | 3.5 | ≤5 | 11 | 13 | ≤20 |

| 3.5 | 4.5 | ≤6 | 13 | 18 | ≤24 |

| 4.5 | 7 | ≤8 | 18 | 21 | ≤36 |

| 7 | 10 | ≤12 | 21 | No Restrictions | ≤40 |

| 10 | 11 | ≤16 | – | ||

[mm]

| |||||

|---|---|---|---|---|---|

| Diameter | Machining Depth (Approximate) | Diameter | Machining Depth (Approximate) | ||

| > | ≤ | > | ≤ | ||

| 2.999 | 3.5 | ≦7 | 9 | 11 | ≦31 |

| 3.5 | 4.5 | ≦11 | 11 | 13 | ≦39 |

| 4.5 | 6 | ≦15 | 13 | 17 | ≦47 |

| 6 | 7 | ≦19 | 17 | 21 | ≦63 |

| 7 | 9 | ≦23 | 21 | No Restrictions | ≦73 |

The auto-quotable effective depths are different due to reamer machining when fit tolerance is H7 for the following diameters.

[mm]

| Diameters Using Reamer | Effective Depth (Approximate) | ||||||

|---|---|---|---|---|---|---|---|

| Pre-Hardened Steel & Tool Steel |

| Stainless steel | Aluminum | Resin |

| |

| 2 | ≤ Diameter * 10 | ≤ Diameter * 9 | ≤ Diameter * 6 | ≤ Diameter * 9 | ≤ Diameter * 10 | ≤ Diameter * 12 | ≤ Diameter * 6 |

| 3 | ≤ Diameter * 9 | ≤ Diameter * 8 | ≤ Diameter * 9 | ≤ Diameter * 12 | ≤ Diameter * 8 | ||

| 4 | ≤ Diameter * 10 | ≤ Diameter * 10 | ≤ Diameter * 8 | ≤ Diameter * 10 | ≤ Diameter * 10 | ||

| 5 | ≤ Diameter * 10 | ≤ Diameter * 15 | |||||

| 6 | ≤ Diameter * 8 | ||||||

| 7 | ≤ Diameter * 6 | ||||||

| 8/9 | ≤ Diameter * 5 | ||||||

| 10/11 | ≤100 | ≤ Diameter * 5 | |||||

| 12/13 | |||||||

| 14/15/16 | ≤ Diameter * 9 | ≤ Diameter * 9 | ≤ Diameter * 9 | ≤ Diameter * 9 | |||

| 17/18/19/20 | ≤ Diameter * 8 | ≤ Diameter * 8 | ≤ Diameter * 8 | ≤ Diameter * 8 | |||

Tapped Holes

The available tap sizes and specifiable effective depths for the cutting service are as follows.

Quotable Tap Effective Depths

[mm]

| Tap Diameter | Pitch | Coarse | Fine |

|

| Effective Depth (Approximate) (Pre-Hardened Steel & Tool Steel ) | Effective Depth (Approximate) (Resin) |

|

|---|

| M2 | 0.25 | ✓ | ≤ Tap Diameter * 5 | ≤ Tap Diameter * 3 | ≤ Tap Diameter * 4 | ≤ Tap Diameter * 6 | ≤ Tap Diameter * 2 | |

| 0.4 | ✓ | |||||||

| M2.5 | 0.35 | ✓ | ≤ Tap Diameter * 3 | ≤ Tap Diameter * 5 | ||||

| 0.45 | ✓ | |||||||

| M3 | 0.35 | ✓ | ≤ Tap Diameter * 4 | ≤ Tap Diameter * 5 | ≤ Tap Diameter * 4 | ≤ Tap Diameter * 3 | ||

| 0.5 | ✓ | ≤ Tap Diameter * 5 | ||||||

| M4 | 0.5 | ✓ | ≤ Tap Diameter * 5 | ≤ Tap Diameter * 4 | ||||

| 0.7 | ✓ | ≤ Tap Diameter * 5 | ||||||

| M5 | 0.5 | ✓ | ≤ Tap Diameter * 4 | |||||

| 0.8 | ✓ | ≤ Tap Diameter * 5 | ||||||

| M6 | 0.75 | ✓ | ≤ Tap Diameter * 4 | |||||

| 1 | ✓ | ≤ Tap Diameter * 5 | ||||||

| M8 | 0.75 | ✓ | ≤ Tap Diameter * 4 | |||||

| 1 | ✓ | |||||||

| 1.25 | ✓ | ≤ Tap Diameter * 5 | ||||||

| M10 | 0.75 | ✓ | ≤ Tap Diameter * 4 | |||||

| 1 | ✓ | |||||||

| 1.25 | ✓ | |||||||

| 1.5 | ✓ | ≤ Tap Diameter * 5 | ||||||

| M12 | 1 | ✓ | ≤ Tap Diameter * 4 | |||||

| 1.25 | ✓ | |||||||

| 1.5 | ✓ | |||||||

| 1.75 | ✓ | ≤ Tap Diameter * 4 | ||||||

| M14 | 1 | ✓ | ≤ Tap Diameter * 3 | |||||

| 1.25 | ✓ | |||||||

| 1.5 | ✓ | |||||||

| 2 | ✓ | ≤ Tap Diameter * 2 | ||||||

| M16 | 1 | ✓ | ≤ Tap Diameter * 3 | |||||

| 1.5 | ✓ | |||||||

| 2 | ✓ |

Quotable Tap Effective Depths

[mm]

| Tap Diameter | Coarse | Fine |

|

| Effective Depth (Approximate) (Pre-Hardened Steel & Tool Steel ) | Effective Depth (Approximate) (Resin) |

|

|---|

| No.4-40 | ✓ | ≤ Tap Diameter * 3 | - | - | - | - | |

|---|---|---|---|---|---|---|---|

| No.6-32 | ✓ | ||||||

| No.8-32 | ✓ | ||||||

| No.10-24 | ✓ | ||||||

| No.10-32 | ✓ | ||||||

| 1/4-20 | ✓ | ||||||

| 1/4-28 | ✓ | ||||||

| 5/16-18 | ✓ | ||||||

| 3/8-16 | ✓ | ||||||

| 3/8-24 | ✓ | ||||||

| 1/2-13 | ✓ | ||||||

| 5/8-11 | ✓ |

Notes

- “Display style” drop down menu in the upper right of model viewer can be set to “Unit(inch)” to display all model units in inches.

- For all threads, the thread depth will be entered in mm. The inch value will be shown for reference.

Insert Holes

The available insert sizes and specifiable effective depths for the cutting service are as follows.

Quotable Sizes

[mm]

| Tap Diameter | Pitch | Coarse | Nominal length (Aluminum and resin) |

|

|---|---|---|---|---|

| M2 | 0.4 | ✓ | 0.5D, 1D, 1.5D, 2D | 1D,1.5D,2D |

| M2.5 | 0.45 | ✓ | 0.5D, 1D, 1.5D, 2D | 1D,1.5D,2D |

| M3 | 0.5 | ✓ | 0.5D, 1D, 1.5D, 2D | 1D,1.5D,2D |

| M4 | 0.7 | ✓ | 0.5D, 1D, 1.5D, 2D | 1D,1.5D,2D |

| M5 | 0.8 | ✓ | 0.5D, 1D, 1.5D, 2D | 1D,1.5D,2D |

| M6 | 1 | ✓ | 0.5D, 1D, 1.5D, 2D | 1D,1.5D,2D |

| M8 | 1.25 | ✓ | 0.5D, 1D, 1.5D, 2D | 1D,1.5D,2D |

| M10 | 1.5 | ✓ | 0.5D, 1D, 1.5D, 2D | 1D,1.5D,2D |

| M12 | 1.75 | ✓ | 0.5D, 1D, 1.5D, 2D | 1D,1.5D,2D |

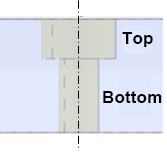

1-Step Holes

For 1-step holes, the upper and lower step can be different combinations of hole and diameter tolerance types. The precision and standards for tapped and precision holes are described above. *Insert holes can also be selected wherever tap holes are selectable. (Only for aluminum and resin)

| Upper Step | Straight hole | Straight hole | Straight hole | Precision hole | Precision hole | Precision hole | Tapped hole | Tapped hole |

|---|---|---|---|---|---|---|---|---|

| Lower Step | Straight hole | Precision hole | Tapped hole | Straight hole | Precision hole | Tapped hole | Straight hole | Tapped pilot hole |

*When the upper step is a tapped hole, a cone shape at the border between the upper and lower steps may occur while machining the pilot hole.

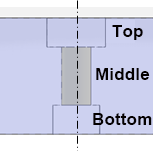

2-Step Holes

For 2-step holes, the upper, middle and lower step can be different combinations of hole diameter tolerance types and hole types. The precision and standards for tapped and precision holes are described above.

*Insert holes can also be selected wherever tap holes are selectable. (Only for aluminum and resin)

| Upper Step | Straight hole | Straight hole | Straight hole | Straight hole | Straight hole | Straight hole | Straight hole |

|---|---|---|---|---|---|---|---|

| Middle Step | Straight hole | Straight hole | Straight hole | Precision hole | Precision hole | Tapped hole | Tapped hole |

| Lower Step | Straight hole | Precision hole | Tapped hole | Precision hole | Straight hole | Precision hole | Straight hole |

| Upper Step | Straight hole | Tapped hole | Tapped hole | Tapped hole | Tapped hole | Tapped hole | Tapped hole | Precision hole |

|---|---|---|---|---|---|---|---|---|

| Middle Step | Tapped pilot hole | Straight hole | Straight hole | Straight hole | Tapped pilot hole | Tapped pilot hole | Tapped pilot hole | Straight hole |

| Lower Step | Tapped hole | Straight hole | Precision hole | Tapped hole | Straight hole | Precision hole | Tapped hole | Straight hole |

| Upper Step | Precision hole | Precision hole | Precision hole | Precision hole | Precision hole | Precision hole | Precision hole |

|---|---|---|---|---|---|---|---|

| Middle Step | Straight hole | Straight hole | Precision hole | Precision hole | Tapped hole | Tapped hole | Tapped pilot hole |

| Lower Step | Precision hole | Tapped hole | Precision hole | Straight hole | Precision hole | Straight hole | Tapped hole |

*When the upper or lower step is a tapped hole, a cone shape at the border between it and the middle step may occur while machining the pilot hole.

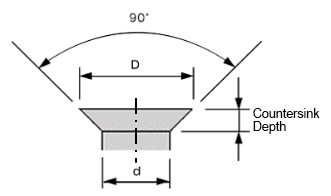

Countersunk Holes

Slotted Holes

The auto-quotable machining depth varies depending on the width.

Auto-Quotable Effective Depths

[mm]

| Steel, Pre-Hardened Steel & Tool Steel | |||||

|---|---|---|---|---|---|

| Width | Machining Depth (Approximate) | Width | Machining Depth (Approximate) | ||

| > | ≤ | > | ≤ | ||

| 2.5 | 3 | ≤10 | 8 | 10 | ≤40 |

| 3 | 4 | ≤12 | 10 | 12 | ≤50 |

| 4 | 5 | ≤16 | 12 | 16 | ≤60 |

| 5 | 6 | ≤20 | 16 | 20 | ≤80 |

| 6 | 8 | ≤30 | 20 | No Restrictions | ≤100 |

[mm]

| Aluminum | |||||

|---|---|---|---|---|---|

| Width | Machining Depth (Approximate) | Width | Machining Depth (Approximate) | ||

| > | ≤ | > | ≤ | ||

| 2.5 | 3 | ≤12.5 | 8 | 10 | ≤40 |

| 3 | 4 | ≤15 | 10 | 12 | ≤50 |

| 4 | 5 | ≤20 | 12 | 16 | ≤60 |

| 5 | 6 | ≤25 | 16 | 20 | ≤80 |

| 6 | 8 | ≤30 | 20 | No Restrictions | ≤100 |

[mm]

| Stainless steel | |||||

|---|---|---|---|---|---|

| Width | Machining Depth (Approximate) | Width | Machining Depth (Approximate) | ||

| > | ≤ | > | ≤ | ||

| 2.5 | 3 | ≤10 | 8 | 10 | ≤32 |

| 3 | 4 | ≤12 | 10 | 12 | ≤40 |

| 4 | 5 | ≤16 | 12 | 16 | ≤48 |

| 5 | 6 | ≤20 | 16 | 20 | ≤64 |

| 6 | 8 | ≤24 | 20 | No Restrictions | ≤80 |

[mm]

| Resin | |||||

|---|---|---|---|---|---|

| Width | Machining Depth (Approximate) | Width | Machining Depth (Approximate) | ||

| > | ≤ | > | ≤ | ||

| 2.5 | 3 | ≤7.5 | 10 | 12 | ≤30 |

| 3 | 4 | ≤10 | 12 | 18 | ≤40 |

| 4 | 6 | ≤15 | 18 | No Restrictions | ≤60 |

| 6 | 10 | ≤20 | – | ||

[mm]

| |||||

|---|---|---|---|---|---|

| Width | Machining Depth (Approximate) | Width | Machining Depth (Approximate) | ||

| > | ≤ | > | ≤ | ||

| 2.5 | 3 | ≤14 | 8 | 10 | ≤34 |

| 3 | 4 | ≤17 | 10 | 12 | ≤44 |

| 4 | 5 | ≤19 | 12 | 16 | ≤54 |

| 5 | 6 | ≤22 | 16 | 20 | ≤64 |

| 6 | 8 | ≤24 | 20 | No Restrictions | ≤74 |

Precision Slotted Holes

regardless of pitch.

regardless of pitch. Precision Ranges that can be Specified

[mm]

| Width | Accuracy Ranges | |||

|---|---|---|---|---|

| > | ≤ | Fit Tolerance | Minimum Bidirectional Tolerance | Minimum Unidirectional Tolerance Range |

| – | 3 | Grade IT7 or higher | 0.005 | 0.01 |

| 3 | 6 | 0.006 | 0.012 | |

| 6 | 10 | 0.008 | 0.015 | |

| 10 | 18 | 0.009 | 0.018 | |

| 18 | 30 | 0.011 | 0.021 | |

| 30 | 50 | 0.013 | 0.025 | |

| 50 | 80 | 0.015 | 0.03 | |

| 80 | 120 | 0.018 | 0.035 | |

| 120 | 180 | 0.02 | 0.04 | |

| 180 | 250 | 0.023 | 0.046 | |

| 250 | 315 | 0.026 | 0.052 | |

| 315 | 400 | 0.029 | 0.057 | |

| 400 | 500 | 0.032 | 0.063 | |

Auto-Quotable Effective Depths

[mm]

| Steel, Pre-Hardened Steel & Tool Steel | |||||

|---|---|---|---|---|---|

| Width | Effective Depth (Approximate) | Width | Effective Depth (Approximate) | ||

| > | ≤ | > | ≤ | ||

| 2.5 | 3 | ≤10 | 8 | 10 | ≤40 |

| 3 | 4 | ≤12 | 10 | 12 | ≤50 |

| 4 | 5 | ≤16 | 12 | 16 | ≤60 |

| 5 | 6 | ≤20 | 16 | 20 | ≤80 |

| 6 | 8 | ≤30 | 20 | No Restrictions | ≤100 |

[mm]

| Aluminum | |||||

|---|---|---|---|---|---|

| Width | Effective Depth (Approximate) | Width | Effective Depth (Approximate) | ||

| > | ≤ | > | ≤ | ||

| 2.5 | 3 | ≤12.5 | 8 | 10 | ≤40 |

| 3 | 4 | ≤15 | 10 | 12 | ≤50 |

| 4 | 5 | ≤20 | 12 | 16 | ≤60 |

| 5 | 6 | ≤25 | 16 | 20 | ≤80 |

| 6 | 8 | ≤30 | 20 | No Restrictions | ≤100 |

[mm]

| Stainless steel | |||||

|---|---|---|---|---|---|

| Width | Effective Depth (Approximate) | Width | Effective Depth (Approximate) | ||

| > | ≤ | > | ≤ | ||

| 2.5 | 3 | ≤10 | 8 | 10 | ≤32 |

| 3 | 4 | ≤12 | 10 | 12 | ≤40 |

| 4 | 5 | ≤16 | 12 | 16 | ≤48 |

| 5 | 6 | ≤20 | 16 | 20 | ≤64 |

| 6 | 8 | ≤24 | 20 | No Restrictions | ≤80 |

[mm]

| Resin | |||||

|---|---|---|---|---|---|

| Width | Effective Depth (Approximate) | Width | Effective Depth (Approximate) | ||

| > | ≤ | > | ≤ | ||

| 2.5 | 3 | ≤5 | 10 | 12 | ≤20 |

| 3 | 4 | ≤6 | 12 | 16 | ≤24 |

| 4 | 6 | ≤8 | 16 | 18 | ≤32 |

| 6 | 8 | ≤12 | 18 | 20 | ≤36 |

| 8 | 10 | ≤16 | 20 | No Restrictions | ≤40 |

[mm]

| |||||

|---|---|---|---|---|---|

| Width | Effective Depth (Approximate) | Width | Effective Depth (Approximate) | ||

| > | ≤ | > | ≤ | ||

| 2.5 | 3 | ≤7 | 8 | 10 | ≤31 |

| 3 | 4 | ≤11 | 10 | 12 | ≤39 |

| 4 | 5 | ≤15 | 12 | 16 | ≤47 |

| 5 | 6 | ≤19 | 16 | 20 | ≤63 |

| 6 | 8 | ≤23 | 20 | No Restrictions | ≤73 |

Pockets

All machining points that do not fall under the category of holes or slotted holes are classified as pockets.

Pockets also have an auto-quote range for width, depth and R size (if any).

For shapes with a chamfer of C15 or less that can be machined with a chamfer cutter, there is no depth limit.

Pocket Width/Depth Compatibility Table

[mm]

| Steel, Pre-Hardened Steel | |||||

|---|---|---|---|---|---|

| Width | Machining Depth (Approximate) | Width | Machining Depth (Approximate) | ||

| > | ≤ | > | ≤ | ||

| 2.5 | 3 | ≤10 | 8 | 10 | ≤40 |

| 3 | 4 | ≤12 | 10 | 12 | ≤50 |

| 4 | 5 | ≤16 | 12 | 16 | ≤60 |

| 5 | 6 | ≤20 | 16 | 20 | ≤80 |

| 6 | 8 | ≤30 | 20 | No Restrictions | ≤100 |

[mm]

| Stainless steel | |||||

|---|---|---|---|---|---|

| Width | Machining Depth (Approximate) | Width | Machining Depth (Approximate) | ||

| > | ≤ | > | ≤ | ||

| 2.5 | 3 | ≤10 | 8 | 10 | ≤32 |

| 3 | 4 | ≤12 | 10 | 12 | ≤40 |

| 4 | 5 | ≤16 | 12 | 16 | ≤48 |

| 5 | 6 | ≤20 | 16 | 20 | ≤64 |

| 6 | 8 | ≤24 | 20 | No Restrictions | ≤80 |

[mm]

| Stainless steel | |||||

|---|---|---|---|---|---|

| Width | Machining Depth (Approximate) | Width | Machining Depth (Approximate) | ||

| > | ≤ | > | ≤ | ||

| 2.5 | 3 | ≤10 | 8 | 10 | ≤32 |

| 3 | 4 | ≤12 | 10 | 12 | ≤40 |

| 4 | 5 | ≤16 | 12 | 16 | ≤48 |

| 5 | 6 | ≤20 | 16 | 20 | ≤64 |

| 6 | 8 | ≤24 | 20 | No Restrictions | ≤80 |

[mm]

| Resin | |||||

|---|---|---|---|---|---|

| Width | Effective Depth (Approximate) | Width | Effective Depth (Approximate) | ||

| > | ≤ | > | ≤ | ||

| 2.5 | 3 | ≤7.5 | 10 | 12 | ≤30 |

| 3 | 4 | ≤10 | 12 | 18 | ≤40 |

| 4 | 6 | ≤15 | 18 | No Restrictions | ≤60 |

| 6 | 10 | ≤20 | |||

Pocket R/Height Compatibility Table

[mm]

| Steel, Pre-Hardened Steel & Tool Steel | |||||

|---|---|---|---|---|---|

| R | Machining Depth (Approximate) | R | Machining Depth (Approximate) | ||

| > | ≤ | > | ≤ | ||

| 0.74 | 1.5 | ≤15 | 5 | 6 | ≤50 |

| 1.5 | 3 | ≤20 | 6 | 8 | ≤60 |

| 3 | 4 | ≤30 | 8 | 10 | ≤80 |

| 4 | 5 | ≤40 | 10 | No Restrictions | ≤100 |

[mm]

| Aluminum | |||||

|---|---|---|---|---|---|

| R | Machining Depth (Approximate) | R | Machining Depth (Approximate) | ||

| > | ≤ | > | ≤ | ||

| 0.74 | 1.5 | ≤15 | 5 | 6 | ≤50 |

| 1.5 | 3 | ≤20 | 6 | 8 | ≤60 |

| 3 | 4 | ≤30 | 8 | 10 | ≤80 |

| 4 | 5 | ≤40 | 10 | No Restrictions | ≤150 |

[mm]

| Stainless steel | |||||

|---|---|---|---|---|---|

| R | Machining Depth (Approximate) | R | Machining Depth (Approximate) | ||

| > | ≤ | > | ≤ | ||

| 0.74 | 1.5 | ≤15 | 5 | 6 | ≤40 |

| 1.5 | 3 | ≤20 | 6 | 8 | ≤48 |

| 3 | 4 | ≤24 | 8 | 10 | ≤64 |

| 4 | 5 | ≤32 | 10 | No Restrictions | ≤80 |

[mm]

| Resin | |||||

|---|---|---|---|---|---|

| R | Machining Depth (Approximate) | R | Machining Depth (Approximate) | ||

| > | ≤ | > | ≤ | ||

| 1.249 | 1.5 | ≤7.5 | 5 | 6 | ≤30 |

| 1.5 | 2 | ≤10 | 6 | 10 | ≤40 |

| 2 | 3 | ≤15 | 10 | No Restrictions | ≤50 |

| 3 | 5 | ≤20 | |||