- HELP

- Technical Information

- CNC Turning

- Design Guidelines

- CNC Turned parts Recognition Conditions

CNC Turned parts Recognition Conditions

- CNC Milling automatically recognizes round and square parts.

- This section describes the recognition conditions.

To Recognize CNC Turned parts

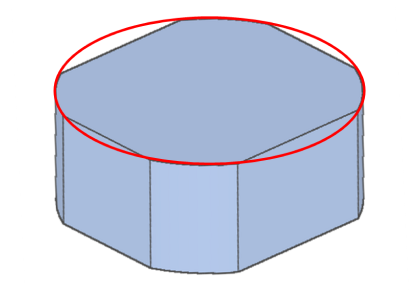

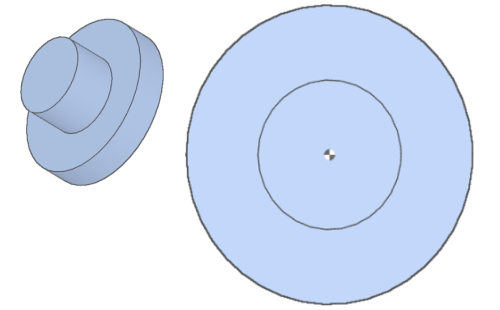

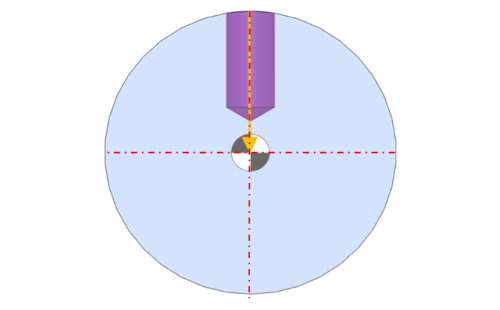

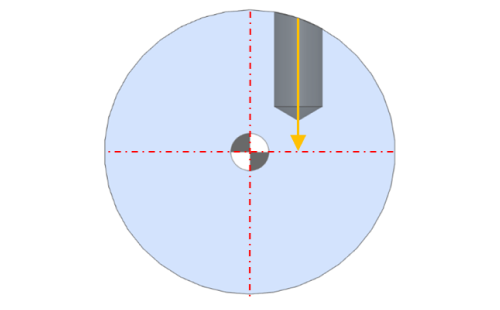

If the outer-most diameter has a cylindrical part, the shape is recognized for CNC Turned parts.

| Turning Part Recognition | Recognition of CNC Milled parts |

|---|---|

|

|

|

|

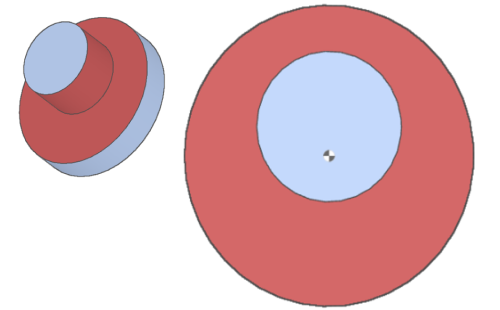

Outer Diameter and Inner Diameter Recognition Conditions

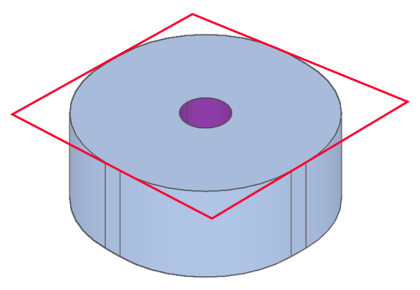

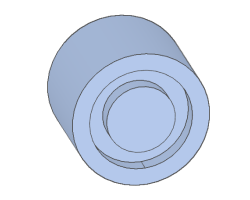

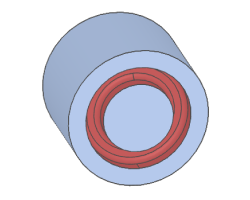

The inner diameter and outer diameter are recognised based on their positional relationship with the central axis.

Recognition of O.D. and I.D. |

Not recognition as “Outer- and Inner Diameter” |

|---|---|

|

|

|

|

Caution

- Automatic recognition is not supported for external threads (outer diameter)

- If a “internal threads (inner diameter) and hole” is recognized, the color attribute/CAD attribute link age function is enabled.>Automatic Hole Type Recognition

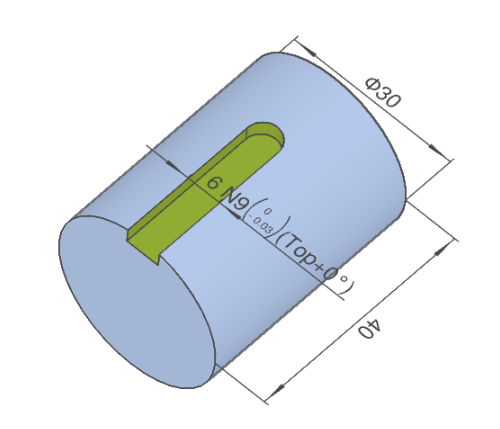

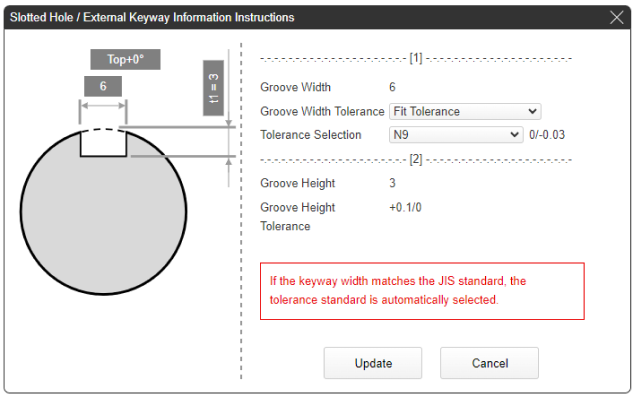

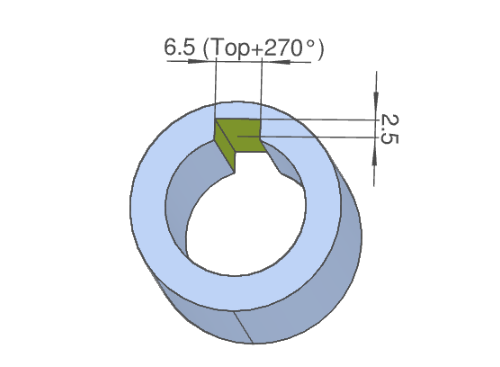

Keyway Recognition Conditions

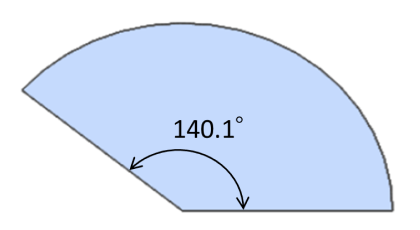

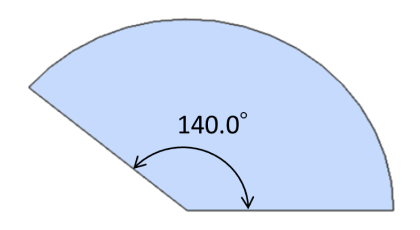

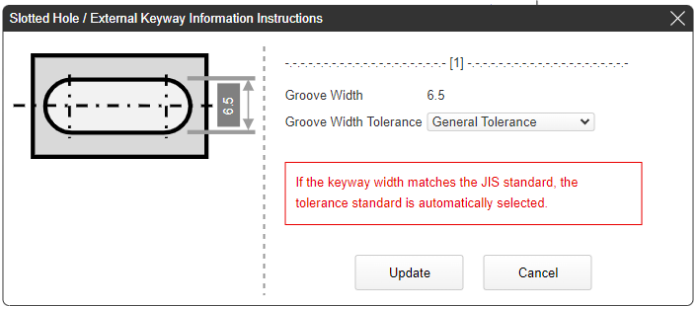

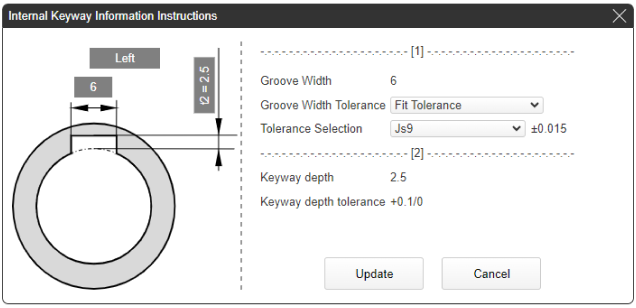

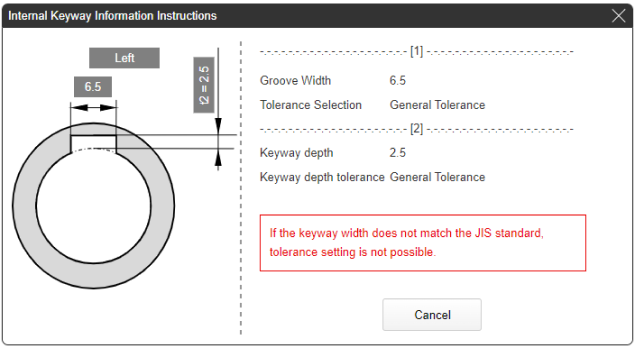

For keyways that match the JIS standard (B 1301:1996), tolerances are automatically set and can be changed in the dialog. *The default settings can be customized in user settings.

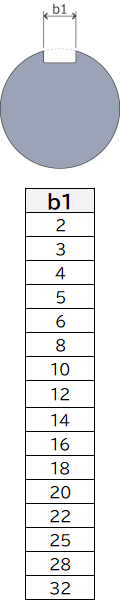

Key width specification |

Recognized as a keyway |

Not recognized as a keyway |

|---|

|

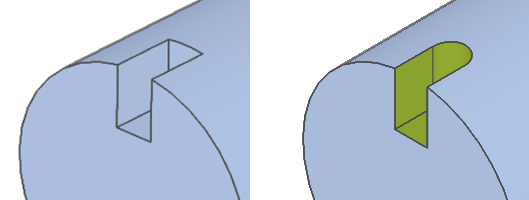

Width recognized as an external keyway (keyseat)

|

Matches [b1] specifications: The fit tolerance of the external keyway (keyseat) is set automatically

|

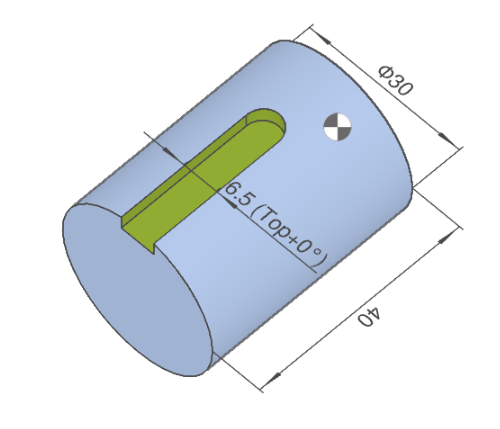

Does not match [b1] specifications: The fit tolerance of the slotted hole is set manually

|

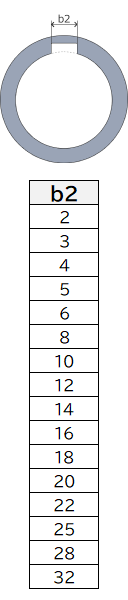

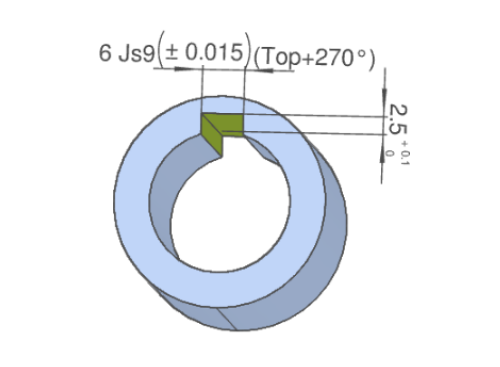

Width recognised as an internal keyway

|

Matches [b2] specifications: The fit tolerance of the internal keyway is set automatically

|

Does not match [b2] specifications: Handled as "general tolerance" for internal keyway and the tolerance cannot be specified

|

Caution

- If the blind internal corners are not rounded, the shape is not recognized as an “external keyway” and the fit tolerance cannot be specified.

- If tolerance settings are required, design the keyseat with round corners that match the groove width.

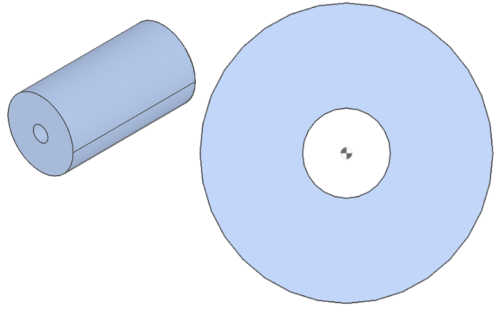

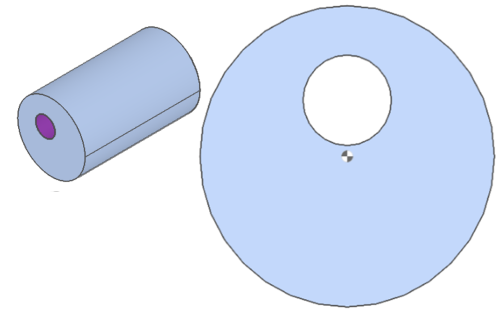

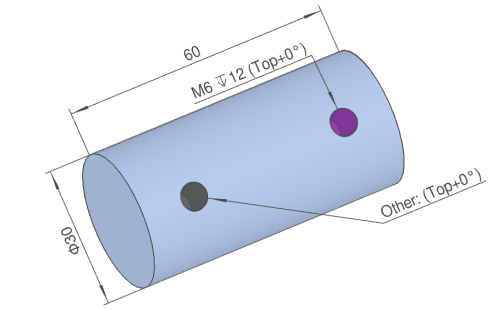

Cylinder Side Hole Recognition Conditions

- A Hole that is oriented to the central axis will be recognized as a “hole” for automatic quotation.

- If it is not oriented to the central axis, it will be recognized as an “other hole” and is not supported by automatic quotation.

- A chamfer will be added to the top of the hole during machining whether or not one is included in the model.

Recognized as a "hole" |

Not recognized as a "hole" |

|---|---|

|

|

End Face Groove Recognition Conditions

If the bottom of the end face groove is curved it is not recognized. Design with sharp internal corners.

Recognized as an "end face groove" |

Not recognized as an "end face groove" |

|---|---|

|

|