- HELP

- Technical Information

- Sheet metal

- Applicable parts/Materials

- Material Properties

Material Properties

Ferrous Metals

A wide range of rolled steel products are available.

These products require surface treatment after processing, as they are prone to rusting.

Available surface treatments are painting, electroless nickel plating, black oxide, and trivalent chromate (clear and black).

|

Low Carbon Steel (Cold Rolled) |

| Cold-rolled steel sheet for use in general type pressing. Characterized by its high dimensional accuracy and attractive surface finish. The standard plate thickness is generally between 0.2 mm and 3.2 mm. |

|

Low Carbon Steel (Hot Rolled) |

| Hot-rolled soft steel sheet for general use and deep drawing. The standard plate thickness is generally 1.2 mm or more. The material is commonly used in products with medium plate thicknesses. |

|

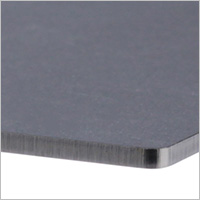

1018 Carbon Steel (Hot Rolled) |

| This is a typical rolled steel for general structural use. It has high strength and is used in a wide range of applications such as construction and machinery. The surface is covered with a black oxide film and is also called black film material. |

|

Low Carbon Steel(Hot Rolled) for International Economy |

| Mill scale steel will be used for 6.0mm thickness International Economy product. Please note the difference in appearance. |

Stainless Steel

A wide range of 304 SS and 430 SS products are available. The most common finishes are “2B” and “NO.1”.

“One side #400 polished” and ‘one side hairline’ can be selected when required.

A protective sheet (one side only) is attached to protect the finish.

|

304 Stainless Steel (2B) |

| The most common type of stainless steel. Provides excellent corrosion resistance, toughness, ductility, machinability and weldability. Used in a wide range of applications. The surface has a slightly glossed finish. |

|

304 Stainless Steel (Single-Sided #400-Grit Polished) |

| A material with a highly attractive surface finish commonly used for exterior covers. The surface has a mirror-like glossed finish onto which a small amount of polishing marks may remain. |

|

304 Stainless Steel (Single-sided hairline finish) |

| This is a surface finishing material characterized by long, continuous, hair-like polished grains. The surface is low-gloss to create a relaxed atmosphere. |

|

304 Stainless Steel (Single-sided #4 Brushed) |

Common among polished stainless steels.

Used in a wide range of applications. |

|

430 Stainless Steel (2B) |

| A common type of ferritic stainless steel. Has a glossier surface finish than 304 Stainless Steel and is characterized by its magnetic properties. |

|

304 Stainless Steel(No.1) |

|

Aluminum

Generally used in sheet metal processing, 5052 aluminum alloy has excellent corrosion resistance, workability, and weldability, and is the most widely distributed aluminum.

Although it is a rust-resistant aluminum, it may corrode depending on environmental conditions.

Anodizing is used to prevent any corrosion.

|

6061 Aluminum Alloy |

| Popular aluminum alloy with excellent corrosion resistance, used in many industries and applications. |

|

5052 Aluminum Alloy |

| The most versatile aluminum alloy. |

Pre-finished Sheets

Surfaces cut during processing will not be plated.

Because a surface treatment is not required after processing, delivery can be made in a relatively short time.

For more information, please click here.

Ferrous Metals

Both have excellent corrosion resistance.

Cold Rolled Low Carbon Steel (Galvanized) has a higher corrosion resistance than Cold Rolled Low Carbon Steel (Electrolytic Zinc Plating) because the plating is thicker.

|

Cold Rolled Low Carbon Steel (Electrolytic Zinc Plating) |

| A plated steel sheet with good corrosion resistance. Because of the properties of the material, there may be some marks on the surface. The surface is gray. |

|

Cold Rolled Low Carbon Steel (Galvanized) |

| Also used in building materials and has high corrosion resistance.The surface is the color of silver. |

Aluminum

Has better corrosion and wear resistance when compared to other unfinished products and can have a shorter delivery and lower cost than surface treated products.

Due to the characteristics of the material, cracks may form in the bend areas and the plating may peel off.

|

5052 AL Alloy Pre-Finish, Clear Anodize |

| The surface is silver. |

|

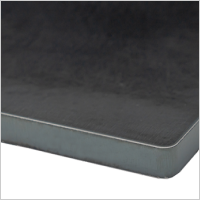

5052 AL Alloy Pre-Finish, Black Anodize |

| The surface is black. |

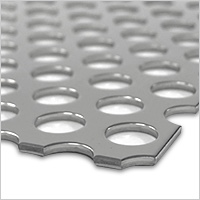

Perforated Metal

Perforated steel sheets are used in a wide range of applications, such as ventilation covers and filters.

It is relatively low cost compared to cutting holes and patterns in solid steel sheets.

Correction for warping is performed at the time of shipment but some distortion will remain due to the characteristics of the material.

|

Perforated Metal – 60° Staggered Round Hole Type – (304 Stainless Steel-BA, Bright Annealed) |

|

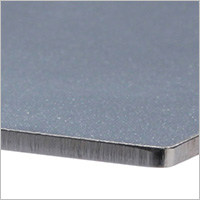

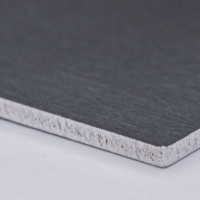

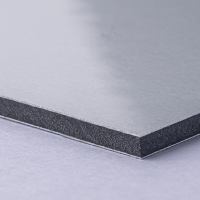

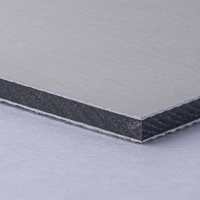

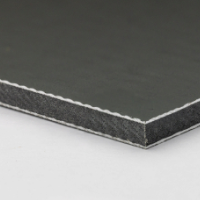

Aluminum composite sheet

Aluminum composite materials have a layered structure of aluminum + polyethylene foam + aluminum.

Because the surface material is thin, it is lighter than metal sheets and has superior rigidity to resin.

Can be used for applications like equipment cover panels for reducing weight while maintaining rigidity.

Due to the characteristics of the material, the metal edges may become sharp.

|

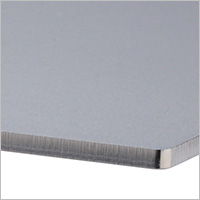

Aluminum composite sheet – Silver |

| The surface is silver (glossy). A popular alternative to stainless steel and aluminum panels. |

|

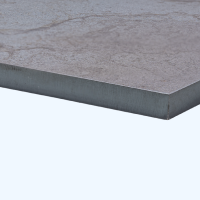

Aluminum composite sheet – Frosted Silver |

| The surface is silver (matte). A popular alternative to stainless steel and aluminum panels. |

|

Aluminum composite sheet – Black |

| The surface is black. A popular alternative to steel panels for applications that require less light reflection. |