- HELP

- Technical Information

- CNC Milling

- Accuracy and Machining Specifications

- Specifiable Dimensional Tolerances

Specifiable Dimensional Tolerances

Dimensional Tolerances

When uploading 3D CAD data, you can specify any dimensions/tolerances for parts where dimensions and tolerances are not displayed.

The minimum specifiable value ranges for tolerances depends on the combination of shape elements.

Depending on other settings, in-range precision may not be covered by the service.

Shape Elements and Minimum Value Ranges for Tolerances

[mm]

| Steel, Pre-Hardened Steel, Stainless steel, Aluminum | |||||

|---|---|---|---|---|---|

| Shape Element ①/Shape Element ② | Blank Surface | Pockets | Precision Holes/Other Hole Types | Precision Slotted Holes | Straight Holes (No Precision) Tapped Holes/Countersunk Holes/Slotted Holes |

| Blank Surface *1 | 0.02 | 0.02 | 0.02 | 0.02 | 0.2 |

| Pockets *2 | – | ||||

| Precision Holes/Other Hole Types | – | ||||

| Precision Slotted Holes | – | ||||

| Straight Holes (No Precision) Tapped Holes/Countersunk Holes/Slotted Holes | – | ||||

*If the range is less than 0.2, trivalent chromate (white) is not available as a surface treatment via the service.

| Shape Element ①/Shape Element ② | Blank Surface | Pockets | Precision Holes/Other Hole Types | Precision Slotted Holes | Straight Holes (No Precision) Tapped Holes/Countersunk Holes/Slotted Holes |

|---|---|---|---|---|---|

| Blank Surface *1 | 0.1(±0.05) | 0.1(±0.05) | 0.1(±0.05) | 0.1(±0.05) | 0.2(±0.1) |

| Pockets *2 | – | 0.04(±0.02) | 0.04(±0.02) | 0.04(±0.02) | |

| Precision Holes/Other Hole Types | – | ||||

| Precision Slotted Holes | – | ||||

| Straight Holes (No Precision) Tapped Holes/Countersunk Holes/Slotted Holes | – |

[mm]

| Resin | |||||

|---|---|---|---|---|---|

| Shape Element ①/Shape Element ② | Blank Surface | Pockets | Precision Holes/Other Hole Types | Precision Slotted Holes | Straight Holes (No Precision) Tapped Holes/Countersunk Holes/Slotted Holes |

| Blank Surface *1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 |

| Pockets *2 | – | ||||

| Precision Holes/Other Hole Types | – | ||||

| Precision Slotted Holes | – | ||||

| Straight Holes (No Precision) Tapped Holes/Countersunk Holes/Slotted Holes | – | ||||

[mm]

|

|||||

|---|---|---|---|---|---|

| Shape Element ①/Shape Element ② | Blank Surface | Pockets | Precision Holes/Other Hole Types | Precision Slotted Holes | Straight Holes (No Precision) Tapped Holes/Countersunk Holes/Slotted Holes |

| Blank Surface *1 | 0.2 | – | 0.2 | 0.2 | 0.2 |

| Pockets *2 | – | ||||

| Precision Holes/Other Hole Types | |||||

| Precision Slotted Holes | – | ||||

| Straight Holes (No Precision) Tapped Holes/Countersunk Holes/Slotted Holes | – | ||||

| *1 Blank Surface: The entire surface used for external dimensions. |

|

| *2 Pocket: A cutting surface other than a blank surface. |

|

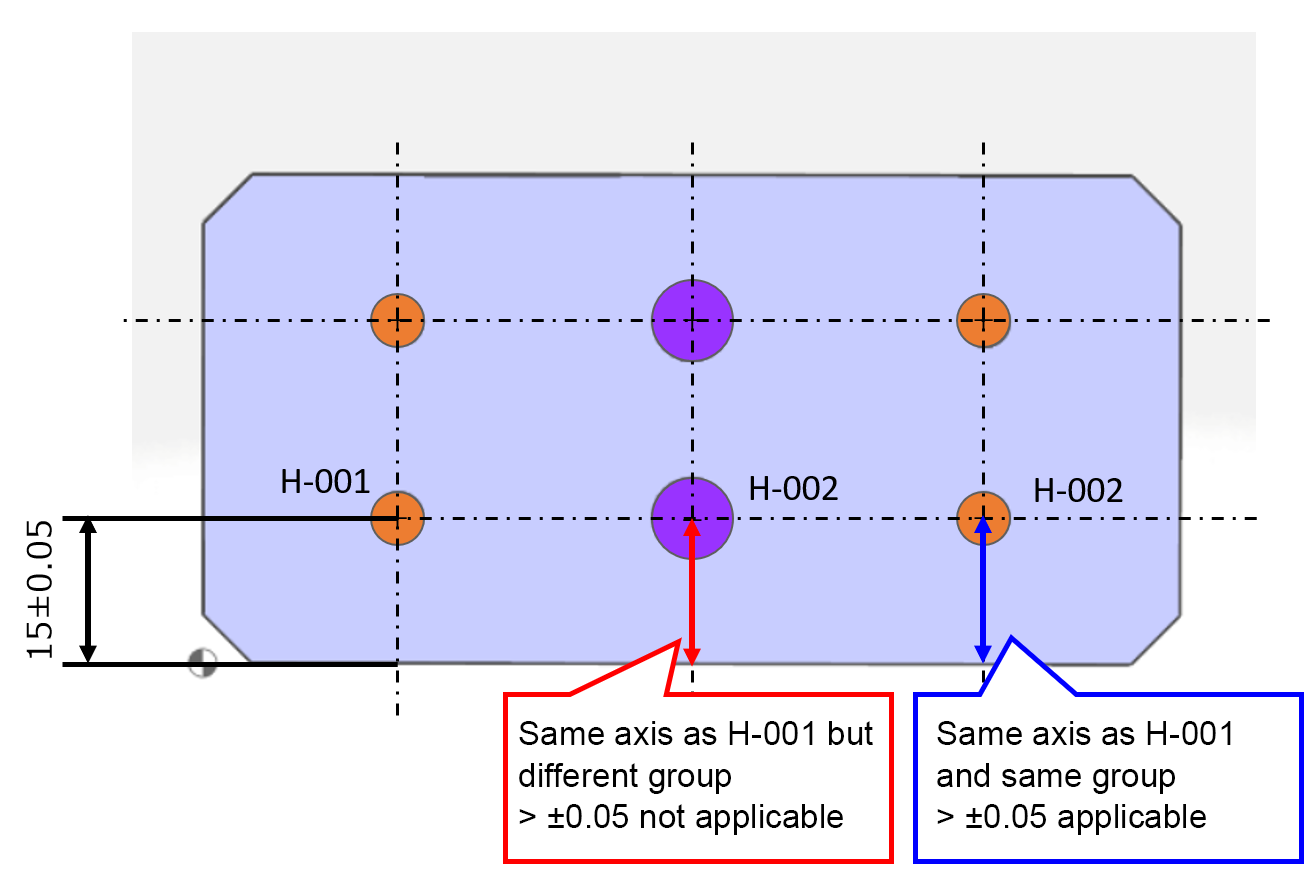

Duplicate dimension application conditions

- Duplicate dimension checks are performed for meviy milled products.

- To avoid duplicate instructions, dimensions identifed as duplicates cannot be set.

- Logic (1)

- Holes of the same diameter that exist on the same plane are treated as holes of the same group.

- When dimensional tolerances are specified from hole to hole or from hole to blank or pocket surface, the dimensions are also applied to any coaxial holes in the same group, and duplicate checks are performed.

When dimensional tolerances are specified for H-001, they are also applied to H-002 on the same axis and in the same group.

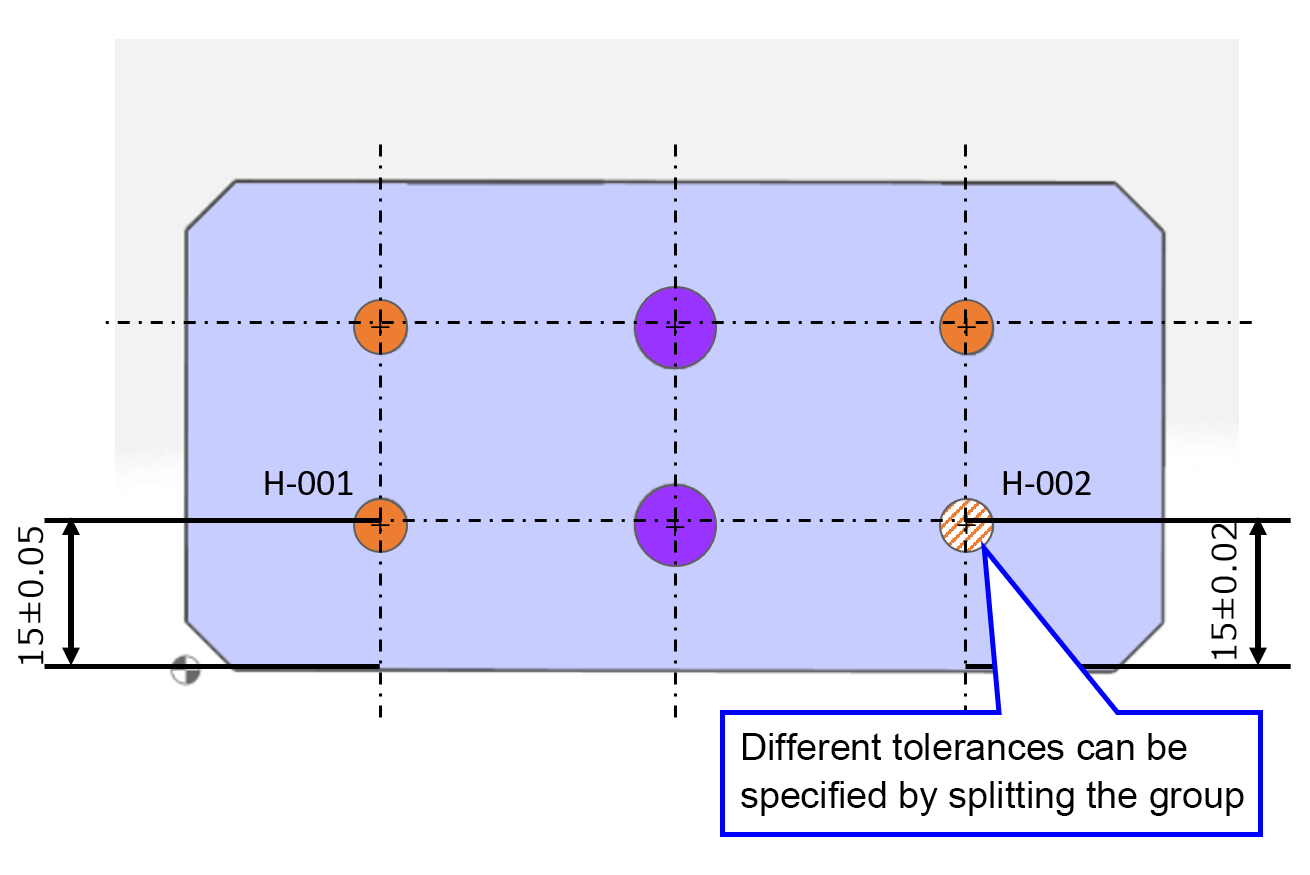

If you want to specify different dimension tolerances for H-001 and H-002, you first need to split the group.

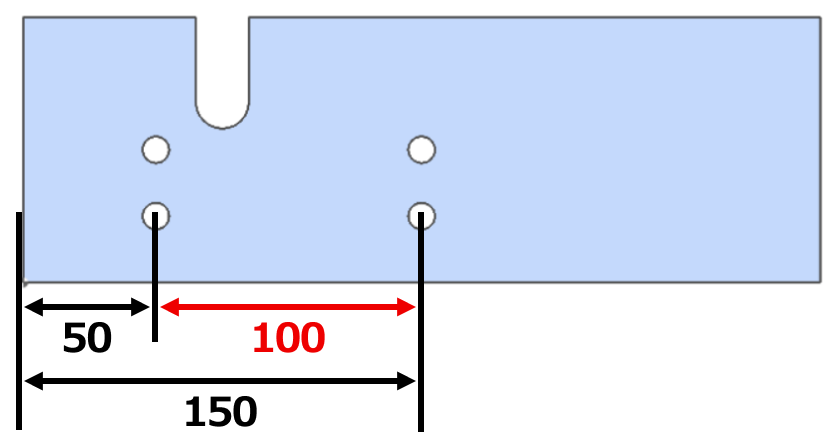

Logic (2)

Dimensions that can be calculated from other dimensions are determined to be duplicated.

When dimensions “50” and “150” are specified, the dimension “100” can be found by subtracting 50 from 150 and is therefore determined to be duplicated.

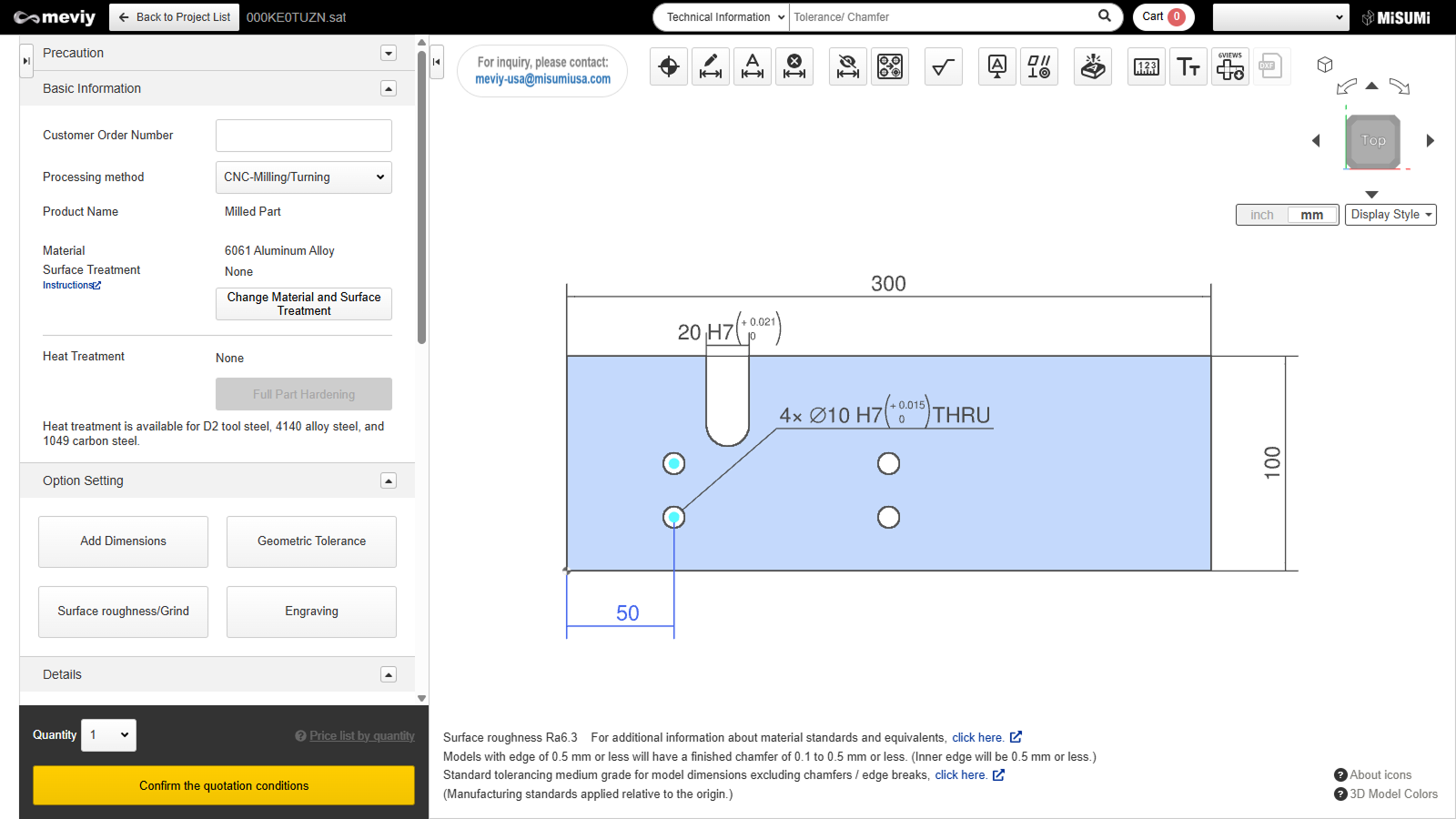

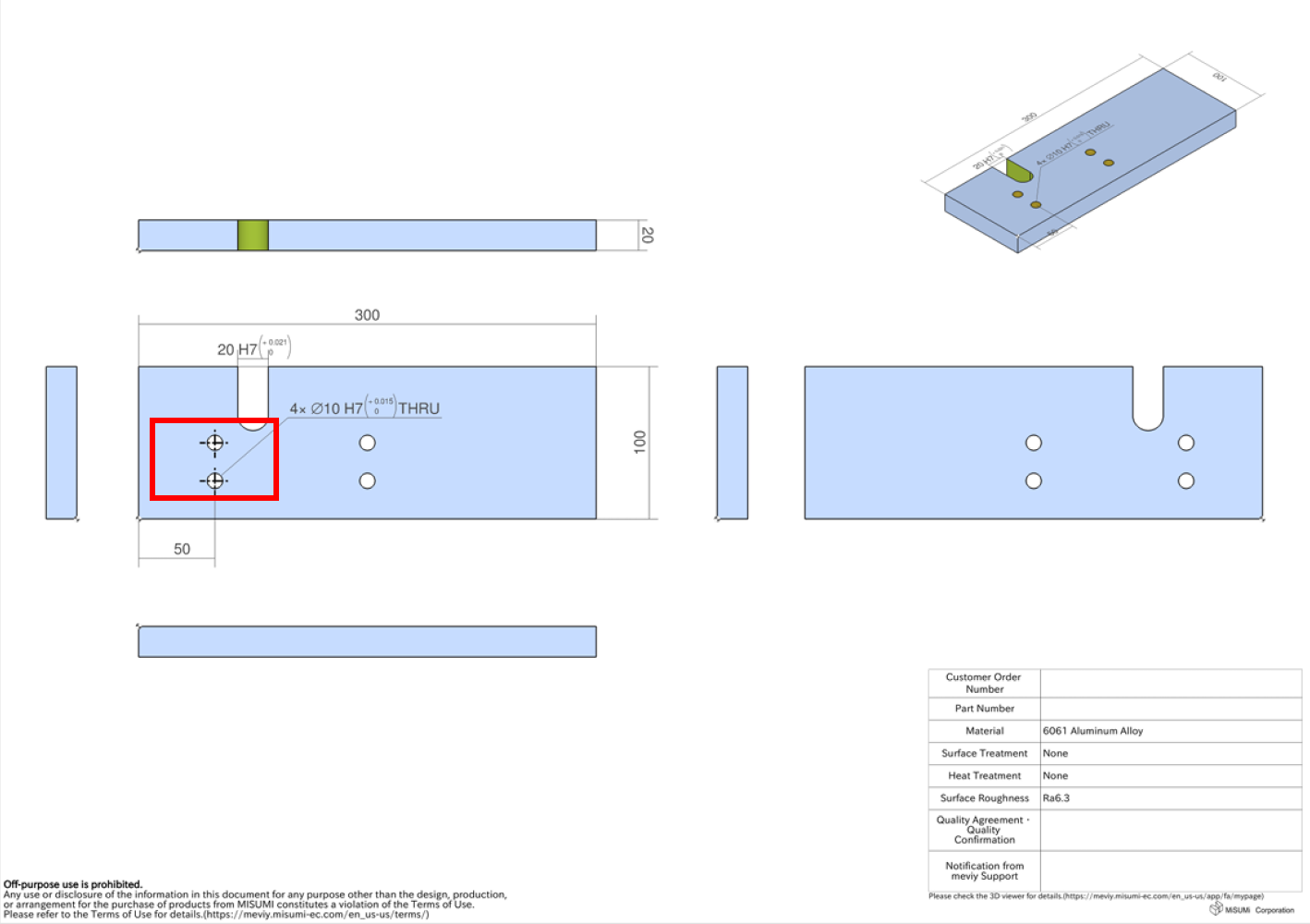

Visualization of dimensioned features

Dimensioned features are indicated by highlights or dashed lines.

■How to display on 3D Viewer

- Clicking a dimension highlights the holes to which that dimension applies.

- (In the image, the bottom-left hole and the top-left hole)

■How to display on simple 2D drawings

Dimensions applied to holes are indicated by a dashed line.

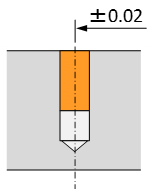

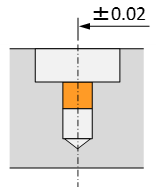

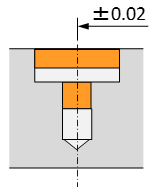

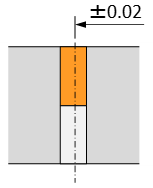

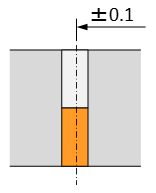

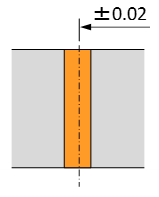

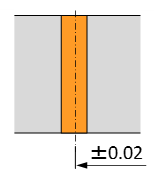

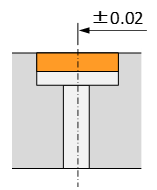

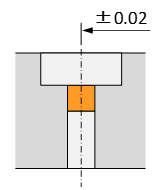

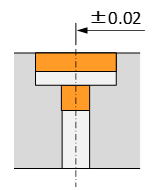

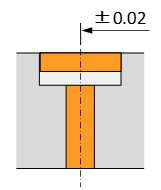

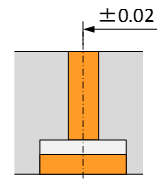

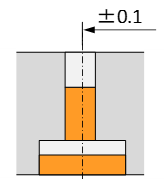

Important Points when Specifying Dimensional Tolerances for Precision Holes

As mentioned above under “Dimensional Tolerance,” when specifying dimensional tolerance for a precision hole, the minimum tolerance value (range) is generally 0.04.

However, there is an exception where the minimum tolerance value (range) is 0.2.

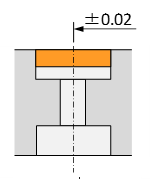

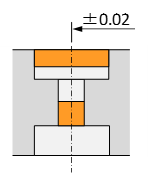

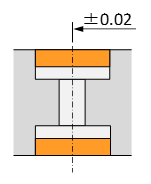

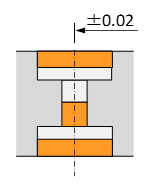

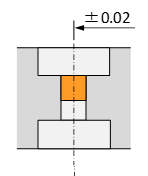

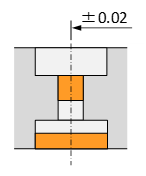

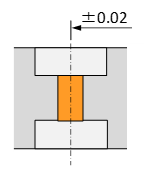

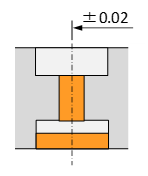

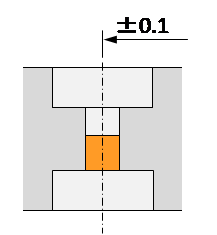

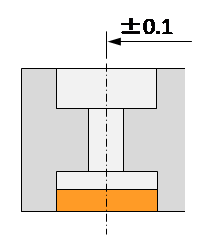

*The orange area is the effective depth range of a precision hole.

0-Step/1-Step Holes (Counterbored Holes), Blind

|

||

0-Step Holes, Through

|

|

|

|

|

|

|

|

|

||

1-Step Holes (Counterbored), Through

|

|

|

|

|

||

|

|

|

|

|

|

2-Step Holes

|

|

|

|

|

||

|

|

|

|

||

|

|

|

|

||

|

|

|

|

|

|