- HELP

- Technical Information

- CNC Milling

- Accuracy and Machining Specifications

- Default General Tolerance Standards

Default General Tolerance Standards

The cutting service does not display dimensions or tolerances when 3D CAD data is uploaded other than external dimensions and hole information, assuming that the customer specifies tolerances of their choice.

This section describes the finish of parts where dimensions and tolerances are not displayed.

Default General Tolerance Standards for Machined Dimensions

(Standard products conform to JIS B 0405:1991/JIS B 0419:1991, International Economy products conform to the standards of the country of manufacture.)

The following standards are applied to the origin according to machining standards.

The origin can be moved to any position.

Length, Excluding Chamfer, Dimensional Tolerances

[mm]

| Product lineup | Tolerance Grade | Base Dimensions | ||||||

|---|---|---|---|---|---|---|---|---|

| Symbol | Description | ≥0.5 ≤3 | >3 ≤6 | >6 ≤30 | >30 ≤120 | >120 ≤400 | >400 ≤1000 | |

| Standard | m | Medium | ±0.1 | ±0.1 | ±0.2 | ±0.3 | ±0.5 | ±0.8 |

| International Economy | – | – | ±0.1 | ±0.1 | ±0.2 | ±0.3 | ±0.5 | ±0.8 |

Tolerances for Chamfer Length Dimensions (Corner Radius or Corner Chamfer Dimensions)

[mm]

| Product lineup | Tolerance Grade | Base Dimensions | |||

|---|---|---|---|---|---|

| Symbol | Description | ≥0.5 ≤3 | >3 ≤6 | >6 | |

| Standard | C | Rough | ±0.4 | ±1 | ±2 |

| International Economy | – | – | ±0.4 | ±1 | ±2 |

Angle Dimensional Tolerances

[mm]

| Product lineup | Tolerance Grade | Length of the Shorter Angle Edge | |||||

|---|---|---|---|---|---|---|---|

| Symbol | Description | ≤10 | >10 ≤50 | >50 ≤120 | >120 ≤400 | >400 | |

| Standard | m | Medium | ±1° | ±30′ | ±20′ | ±10′ | ±5′ |

| International Economy | – | – | ±1° | ±30′ | ±20′ | ±10′ | ±5′ |

General Tolerances of Perpendicularity

[mm]

| Product lineup | Tolerance Grade | Nominal Length of the Shorter Edge | ||

|---|---|---|---|---|

| Symbol | ≤100 | >100 ≤300 | >300 ≤1,000 | |

| Standard | K | 0.4 | 0.6 | 0.8 |

| International Economy | – | 0.4 | 0.6 | 0.8 |

General Tolerances of Straightness and Flatness

[mm]

| Product lineup | Tolerance Grade | Nominal Length | ||||

|---|---|---|---|---|---|---|

| Symbol | ≤10 | >10 ≤30 | >30 ≤100 | >100 ≤300 | >300 ≤1,000 | |

| Standard | K | 0.05 | 0.1 | 0.2 | 0.4 | 0.6 |

| International Economy | – | 0.05 | 0.1 | 0.2 | 0.4 | 0.6 |

(Related) Changing a design’s origin.

Width (Y) and thickness (Z) tolerances of polished flat bar

1018 Carbon Steel (polished), 1045 Carbon Steel (polished), 304 Stainless Steel (polished) Excerpt from JIS G 3123:2004 / JIS G 4318:2016

| Tolerance Grade | Width Tolerance/Thickness Tolerance | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Symbol | Description | > | 3 | 6 | 10 | 18 | 30 | 50 | 80 | 120 |

| ≤ | 6 | 10 | 18 | 30 | 50 | 80 | 120 | 180 | ||

| IT | 13 | -0.18~0 | -0.22~0 | -0.27~0 | -0.33~0 | -0.39~0 | -0.46~0 | -0.54~0 | -0.63~0 | |

6063 Aluminum Alloy, Excerpt from JIS H 4040:2015

| Thickness | Width | Thickness Tolerance | Width Tolerance | Thickness | Width | Thickness Tolerance | Width Tolerance |

|---|

| 5 | 15 | ±0.26 | ±0.33 | 12 | 12 | ±0.33 | ±0.33 |

|---|---|---|---|---|---|---|---|

| 20 | ±0.39 | 15 | |||||

| 30 | 20 | ±0.39 | ±0.39 | ||||

| 40 | ±0.33 | ±0.52 | 30 | ||||

| 50 | 40 | ±0.52 | |||||

| 60 | ±0.78 | 50 | |||||

| 100 | ±1.00 | 60 | ±0.46 | ±0.78 | |||

| 6 | 15 | ±0.26 | ±0.33 | 100 | ±0.52 | ±1.00 | |

| 20 | ±0.39 | 15 | 15 | ±0.39 | ±0.39 | ||

| 30 | 20 | ||||||

| 40 | ±0.33 | ±0.52 | 30 | ||||

| 50 | 40 | ±0.52 | |||||

| 60 | ±0.78 | 50 | ±0.52 | ||||

| 100 | ±1.00 | 60 | ±0.46 | ±0.78 | |||

| 8 | 15 | ±0.33 | ±0.33 | 100 | ±0.52 | ±1.00 | |

| 20 | ±0.39 | 20 | 20 | ±0.39 | ±0.39 | ||

| 30 | 30 | ||||||

| 40 | ±0.52 | 40 | ±0.46 | ±0.52 | |||

| 50 | 50 | ||||||

| 60 | ±0.39 | ±0.78 | 60 | ±0.52 | ±0.78 | ||

| 100 | ±0.46 | ±1.00 | 100 | ±0.59 | ±1.00 | ||

| 10 | 10 | ±0.33 | ±0.33 | 25 | 25 | ±0.39 | ±0.39 |

| 15 | 30 | ||||||

| 20 | ±0.39 | 40 | ±0.46 | ±0.52 | |||

| 30 | 50 | ||||||

| 40 | ±0.52 | 60 | ±0.52 | ±0.78 | |||

| 50 | 100 | ±0.59 | ±1.00 | ||||

| 60 | ±0.39 | ±0.78 | 30 | 30 | ±0.46 | ±0.46 | |

| 100 | ±0.46 | ±1.00 | 40 | ±0.52 | |||

| 50 | |||||||

| 60 | ±0.52 | ±0.78 | |||||

| 100 | ±0.59 | ±1.00 | |||||

Resin Precision Assurance

Unlike metal, resin is a material that easily changes shape or dimensions due to factors such as temperature and humidity. Due to this, precision assurance is performed under the following conditions:

· Inspections are performed in temperature-controlled environments.

· Precision assurance is based on the results of inspections performed immediately before shipment.

Surface Roughness

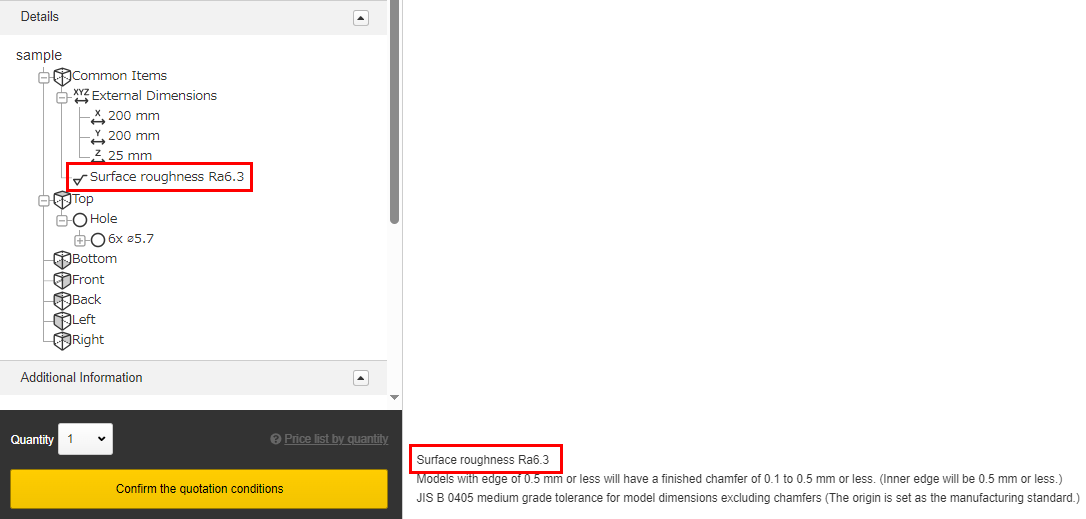

- The default surface roughness reference value is √Ra6.3 (√Rz25).

- A value of 6.3 or 3.2 can be specified when the surface roughness symbol “Ra” is selected in the user settings or initial quotation conditions.

- A value of 25 or 12.5 can be specified if “Rz” is selected.

- The surface roughness is displayed in the tree view and in the lower left corner of the model viewer.

| Symbol | Selected Value | |

|---|---|---|

| Ra |

6.3 |

3.2 |

| Rz |

25 |

12.5 |

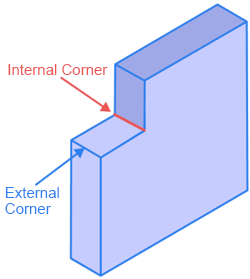

Internal and External Corners

For external sharp corners or corners of C0.5 and smaller, the finish will be as follows:

· Corners C0.1 mm to 0.5 mm or less

For internal sharp corners, the finish will be as follows:

· Internal corners R0.1 to R0.5 mm or less