- HELP

- Technical Information

- Sheet metal

- Design Guidelines

- Countersink Modeling and Selectable Sizes

Countersink Modeling and Selectable Sizes

Metric Thickness Gauge Standard

Modeling Rules for Countersunk Holes

When a conical shape element is detected, it will be identified as a countersink.

| Countersunk Type | Modeling Rules | Example |

|---|---|---|

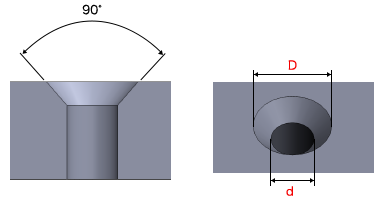

| Metric countersunk hole | Model the angle of the conical shape to be 90°. The ratio between the outer hole diameter (D) and inner hole diameter (d) must be as follows: If d ≤ 4.0 mm, the ratio must be above 1.4, If d > 4.0 mm, the ratio must be above 1.7. |  |

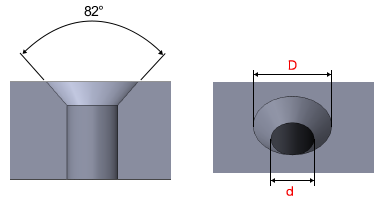

| Inch countersunk hole | Model the angle of the conical shape to be 82°. The ratio between the outer hole diameter (D) and the inner hole diameter (d) must be above 1.4, regardless of the value of d. |  |

Countersunk Hole Identification

The countesunk hole is recognized through a step below.

- The nominal diameter is determined according to the pilot hole diameter range (see table below).

- If the detected hole diameter does not match any of the entries on the list of pilot hole diameters, the hole is treated as a through hole (or tapped hole).

- However, you can change the hole type or hole diameter when configuring the quote settings.

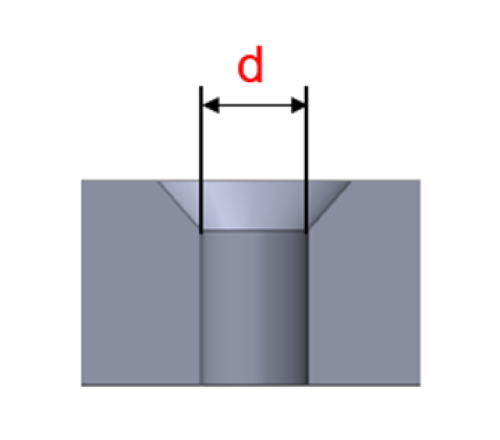

Metric Countersunk Hole

| Countersunk diameter | Pilot hole(d) range | Example |

|---|---|---|

| M3 | 3.2 ≤ d ≤ 4.0 |  |

| M4 | 4.3 ≤ d ≤ 4.8 | |

| M5 | 5.3 ≤ d ≤ 6.5 | |

| M6 | 6.3 ≤ d ≤ 7.0 | |

| M8 | 8.4 ≤ d ≤ 10.0 | |

| M10 | 10.5 ≤ d ≤ 12.0 | |

| M12 | 13.0 ≤ d ≤ 14.5 | |

| M14 | 15.0 ≤ d ≤ 16.5 | |

| M16 | 17.0 ≤ d ≤ 18.5 |

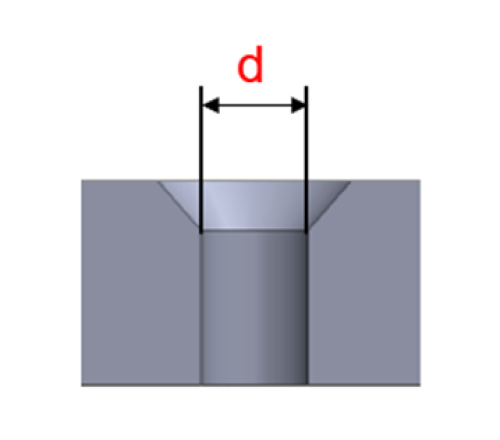

Inch Countersunk Hole

| Countersunk diameter | Pilot hole(d) range | Example |

|---|---|---|

| #0 | 1.27 ≤ d ≤ 2.54 |  |

| #1 | 1.78 ≤ d ≤ 2.79 | |

| #2 | 2.03 ≤ d ≤ 3.05 | |

| #3 | 2.29 ≤ d ≤ 3.3 | |

| #4 | 2.79 ≤ d ≤ 3.81 | |

| #5 | 3.05 ≤ d ≤ 4.32 | |

| #6 | 3.3 ≤ d ≤ 4.83 | |

| #8 | 4.06 ≤ d ≤ 5.33 | |

| #10 | 4.57 ≤ d ≤ 6.1 | |

| #12 | 5.33 ≤ d ≤ 6.35 | |

| 1/4 | 6.1 ≤ d ≤ 7.62 | |

| 5/16 | 7.62 ≤ d ≤ 9.14 | |

| 3/8 | 9.4 ≤ d ≤ 10.67 | |

| 7/16 | 10.92 ≤ d ≤ 12.45 | |

| 1/2 | 12.45 ≤ d ≤ 15.49 | |

| 5/8 | 14.73 ≤ d ≤ 18.8 | |

| 3/4 | 16.26 ≤ d ≤ 23.11 | |

| 7/8 | 21.84 ≤ d ≤ 26.16 |

Countersunk Hole Size Selection for Inch Thickness Gauge Standard

- Available sizes vary depending on material and Sheet Thickness. See the table below for details.

- Countersunk holes cannot be selected for perforated metals or shim plate materials.

Metric Countersunk Hole

| Material | Sheet Thickness (inch) | (mm) | Available Bolt Nominal Diameter | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0.0299 (#22) | 0.759 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.0359 (#20) | 0.912 | M2 | |||||||||||

| 0.0418 (#19) | 1.062 | M2 | |||||||||||

| 0.0478 (#18) | 1.214 | M2 | M2.5 | M3 | |||||||||

| 0.0538 (#17) | 1.367 | M3 | |||||||||||

| 0.0598 (#16) | 1.519 | M2 | M2.5 | M3 | M4 | ||||||||

| 0.0747 (#14) | 1.897 | M2 | M2.5 | M3 | M4 | M5 | |||||||

| 0.0897 (#13) | 2.278 | M2 | M2.5 | M3 | M4 | M5 | |||||||

| 0.1046 (#12) | 2.657 | M2 | M2.5 | M3 | M4 | M5 | M6 | M8 | |||||

| 0.1196 (#11) | 3.038 | M2 | M2.5 | M3 | M4 | M5 | M6 | M8 | M10 | ||||

| 0.1345 (#10) | 3.416 | M2.5 | M3 | M4 | M5 | M6 | M8 | M10 | |||||

| 0.1495 (#9) | 3.797 | M5 | M6 | M8 | M10 | ||||||||

| 0.1644 (#8) | 4.176 | M5 | M6 | M8 | M10 | ||||||||

| 0.1793 (#7) | 4.554 | M6 | M8 | M10 | |||||||||

| 0.1875 (#(3/16)) | 4.763 | M6 | M8 | M10 | |||||||||

| 0.1943 (#6) | 4.935 | M3 | M4 | M5 | M6 | M8 | M10 | M12 | M14 | ||||

| 0.25 (#-) | 6.350 | M4 | M5 | M6 | M8 | M10 | M12 | M14 | |||||

| 0.375 (#-) | 9.525 | M6 | M8 | M10 | M12 | M14 | |||||||

| 0.5 (#(1/2)) | 12.700 | M16 | |||||||||||

| 0.0276 (#24) | 0.701 | |||||||||||

| 0.0336 (#22) | 0.853 | ||||||||||||

| 0.0396 (#20) | 1.006 | M2 | |||||||||||

| 0.0516 (#18) | 1.311 | M2 | M2.5 | M3 | |||||||||

| 0.0635 (#16) | 1.613 | M2 | M2.5 | M3 | M4 | ||||||||

| 0.0785 (#14) | 1.994 | M2 | M2.5 | M3 | M4 | M5 | |||||||

| 0.0934 (#13) | 2.372 | M3 | M4 | M5 | |||||||||

| 0.1084 (#12) | 2.753 | M4 | M5 | M6 | M8 | ||||||||

| 0.1233 (#11) | 3.132 | M4 | M5 | M6 | M8 | M10 | |||||||

| 0.1382 (#10) | 3.510 | M5 | M6 | M8 | M10 | ||||||||

| 0.168 (#8) | 4.267 | M6 | M8 | M10 | |||||||||

| 0.1793 (#7) | 4.554 | M6 | M8 | M10 | |||||||||

| 0.0187 (#26) | 0.475 | |||||||||||

| 0.025 (#24) | 0.635 | ||||||||||||

| 0.0312 (#22) | 0.792 | ||||||||||||

| 0.0375 (#20) | 0.953 | M2 | |||||||||||

| 0.0437 (#19) | 1.110 | ||||||||||||

| 0.05 (#18) | 1.270 | M2 | M2.5 | M3 | |||||||||

| 0.0562 (#17) | 1.427 | M3 | |||||||||||

| 0.0625 (#16) | 1.588 | M2 | M2.5 | M3 | M4 | ||||||||

| 0.0781 (#14) | 1.984 | M2 | M2.5 | M3 | M4 | M5 | |||||||

| 0.0937 (#13) | 2.380 | M3 | M4 | M5 | |||||||||

| 0.1094 (#12) | 2.779 | M2 | M2.5 | M3 | M4 | M5 | M6 | M8 | |||||

| 0.125 (#11) | 3.175 | M2.5 | M3 | M4 | M5 | M6 | M8 | M10 | |||||

| 0.1406 (#10) | 3.571 | M2.5 | M3 | M4 | M5 | M6 | M8 | M10 | |||||

| 0.1719 (#8) | 4.366 | M3 | M4 | M5 | M6 | M8 | M10 | ||||||

| 0.1875 (#7) | 4.763 | M3 | M4 | M5 | M6 | M8 | M10 | ||||||

| 0.25 (#3) | 6.350 | M4 | M5 | M6 | M8 | M10 | |||||||

| 0.5 (#(1/2)) | 12.700 | M16 | |||||||||||

| 0.02 | 0.508 | |||||||||||

| 0.025 | 0.635 | ||||||||||||

| 0.032 | 0.813 | ||||||||||||

| 0.04 | 1.016 | M2 | M3 | ||||||||||

| 0.05 | 1.270 | M2 | M2.5 | M3 | |||||||||

| 0.063 | 1.600 | M2 | M2.5 | M3 | M4 | M5 | |||||||

| 0.08 | 2.032 | M2 | M2.5 | M3 | M4 | M5 | M6 | ||||||

| 0.09 | 2.286 | M2 | M2.5 | M3 | M4 | M5 | M6 | ||||||

| 0.1 | 2.540 | M2 | M2.5 | M3 | M4 | M5 | M6 | M8 | |||||

| 0.125 | 3.175 | M2.5 | M3 | M4 | M5 | M6 | M8 | M10 | |||||

| 0.16 | 4.064 | M5 | M6 | M8 | M10 | ||||||||

| 0.19 | 4.826 | M6 | M8 | M10 | |||||||||

| 0.25 | 6.350 | M8 | M10 | ||||||||||

| 0.3125 | 7.938 | M10 | M12 | M14 | M16 | ||||||||

| 0.375 | 9.525 | M12 | M14 | M16 | |||||||||

| 0.5 | 12.700 | M16 |

Inch Countersunk Hole

| Material | Sheet Thickness (inch) | (mm) | Available Bolt Nominal Diameter | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.0179 (#26) | 0.455 | ||||||||||||||||||

| 0.0239 (#24) | 0.607 | |||||||||||||||||||

| 0.0299 (#22) | 0.759 | |||||||||||||||||||

| 0.0359 (#20) | 0.912 | |||||||||||||||||||

| 0.0418 (#19) | 1.062 | |||||||||||||||||||

| 0.0478 (#18) | 1.214 | #0 | ||||||||||||||||||

| 0.0538 (#17) | 1.367 | #0 | ||||||||||||||||||

| 0.0598 (#16) | 1.519 | #0 | #1 | |||||||||||||||||

| 0.0747 (#14) | 1.897 | #0 | #1 | #2 | #3 | |||||||||||||||

| 0.0897 (#13) | 2.278 | #0 | #1 | #2 | #3 | #4 | ||||||||||||||

| 0.1046 (#12) | 2.657 | #0 | #1 | #2 | #3 | #4 | #5 | #6 | ||||||||||||

| 0.1196 (#11) | 3.038 | #0 | #1 | #2 | #3 | #4 | #5 | #6 | #8 | |||||||||||

| 0.1345 (#10) | 3.416 | #0 | #1 | #2 | #3 | #4 | #5 | #6 | #8 | #10 | ||||||||||

| 0.1495 (#9) | 3.797 | #5 | #6 | #8 | #10 | #12 | ||||||||||||||

| 0.1644 (#8) | 4.176 | #6 | #8 | #10 | #12 | 1/4 | ||||||||||||||

| 0.1793 (#7) | 4.554 | #8 | #10 | #12 | 1/4 | |||||||||||||||

| 0.1875 (#3/16) | 4.763 | #8 | #10 | #12 | 1/4 | |||||||||||||||

| 0.1943 (#6) | 4.935 | #0 | #1 | #2 | #3 | #4 | #5 | #6 | #8 | #10 | #12 | 1/4 | ||||||||

| 0.25 (#2) | 6.350 | #0 | #1 | #2 | #3 | #4 | #5 | #6 | #8 | #10 | #12 | 1/4 | 5/16 | |||||||

| 0.375 (#1) | 9.525 | #0 | #1 | #2 | #3 | #4 | #5 | #6 | #8 | #10 | #12 | 1/4 | 5/16 | 3/8 | 7/16 | 1/2 | 5/8 | |||

| 0.5 (#1/2) | 12.700 | 1/2 | 5/8 | 3/4 | 7/8 | |||||||||||||||

| 0.0217 (#26) | 0.551 | ||||||||||||||||||

| 0.0276 (#24) | 0.701 | |||||||||||||||||||

| 0.0336 (#22) | 0.853 | |||||||||||||||||||

| 0.0396 (#20) | 1.006 | |||||||||||||||||||

| 0.0516 (#18) | 1.311 | #0 | ||||||||||||||||||

| 0.0635 (#16) | 1.613 | #0 | #1 | |||||||||||||||||

| 0.0785 (#14) | 1.994 | #0 | #1 | #2 | #3 | |||||||||||||||

| 0.0934 (#13) | 2.372 | #1 | #2 | #3 | #4 | #5 | ||||||||||||||

| 0.1084 (#12) | 2.753 | #2 | #3 | #4 | #5 | #6 | ||||||||||||||

| 0.1233 (#11) | 3.132 | #4 | #5 | #6 | #8 | |||||||||||||||

| 0.1382 (#10) | 3.510 | #5 | #6 | #8 | #10 | #12 | ||||||||||||||

| 0.168 (#8) | 4.267 | #6 | #8 | #10 | #12 | 1/4 | ||||||||||||||

| 0.1793 (#7) | 4.554 | #8 | #10 | #12 | 1/4 | |||||||||||||||

| 0.0187 (#28) | 0.475 | ||||||||||||||||||

| 0.025 (#24) | 0.635 | |||||||||||||||||||

| 0.0375 (#20) | 0.953 | |||||||||||||||||||

| 0.0437 (#19) | 1.110 | |||||||||||||||||||

| 0.05 (#18) | 1.270 | #0 | ||||||||||||||||||

| 0.0562 (#17) | 1.427 | #0 | #1 | |||||||||||||||||

| 0.0625 (#16) | 1.588 | #0 | #1 | |||||||||||||||||

| 0.0781 (#14) | 1.984 | #0 | #1 | #2 | #3 | |||||||||||||||

| 0.0937 (#13) | 2.380 | #0 | #1 | #2 | #3 | |||||||||||||||

| 0.1094 (#12) | 2.779 | #0 | #1 | #2 | #3 | #4 | #5 | #6 | ||||||||||||

| 0.125 (#11) | 3.175 | #0 | #1 | #2 | #3 | #4 | #5 | #6 | #8 | |||||||||||

| 0.1406 (#10) | 3.571 | #0 | #1 | #2 | #3 | #4 | #5 | #6 | #8 | #10 | #12 | |||||||||

| 0.1719 (#8) | 4.366 | #0 | #1 | #2 | #3 | #4 | #5 | #6 | #8 | #10 | ||||||||||

| 0.1875 (#3/16) | 4.763 | #0 | #1 | #2 | #3 | #4 | #5 | #6 | #8 | #10 | #12 | 1/4 | ||||||||

| 0.25 (#2) | 6.350 | #0 | #1 | #2 | #3 | #4 | #5 | #6 | #8 | #10 | #12 | 1/4 | 5/16 | 3/8 | 7/16 | |||||

| 0.5 (#1/2) | 12.700 | 1/2 | 5/8 | 3/4 | 7/8 | |||||||||||||||

| 5052 Aluminum Alloy 6061 Aluminum Alloy | 0.0202 | 0.513 | ||||||||||||||||||

| 0.025 | 0.635 | |||||||||||||||||||

| 0.032 | 0.813 | |||||||||||||||||||

| 0.04 | 1.016 | |||||||||||||||||||

| 0.05 | 1.270 | #0 | ||||||||||||||||||

| 0.063 | 1.600 | #0 | #1 | |||||||||||||||||

| 0.08 | 2.032 | #0 | #1 | #2 | #3 | |||||||||||||||

| 0.09 | 2.286 | #0 | #1 | #2 | #3 | #4 | #5 | |||||||||||||

| 0.1 | 2.540 | #0 | #1 | #2 | #3 | #4 | #5 | #6 | ||||||||||||

| 0.125 | 3.175 | #0 | #1 | #2 | #3 | #4 | #5 | #6 | #8 | |||||||||||

| 0.16 | 4.064 | #6 | #8 | #10 | #12 | |||||||||||||||

| 0.19 | 4.826 | #8 | #10 | #12 | 1/4 | |||||||||||||||

| 0.25 | 6.350 | #10 | #12 | 1/4 | 5/16 | 3/8 | 7/16 | |||||||||||||

| 0.3125 | 7.938 | 5/16 | 3/8 | 7/16 | 1/2 | |||||||||||||||

| 0.375 | 9.525 | 3/8 | 7/16 | 1/2 | 5/8 | |||||||||||||||

| 0.5 | 12.700 | 1/2 | 5/8 | 3/4 | 7/8 | |||||||||||||||

Countersunk Hole Size Selection for Metric Thickness Gauge Standard

- Available sizes vary depending on material and Sheet Thickness. See the table below for details.

- Countersunk holes cannot be selected for perforated metals or shim plate materials (Cold Rolled Low Carbon Steel (for Shims) or 304 Stainless Steel (H) (for Shims)).

| Material | Sheet Thickness | Countersunk Hole Bolt Nominal Diameter | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 2.0 | M3 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 2.3 | M3 | |||||||||

| 3.2 | M3 | M4 | M5 | |||||||

| 4.5 | M3 | M4 | M5 | M6 | ||||||

| 6.0 | M3 | M4 | M5 | M6 | M8 | M10 | ||||

| 9.0 | M5 | M6 | M8 | M10 | ||||||

| 10.0 | M5 | M6 | M8 | M10 | M12 | M14 | M16 | |||

| 12.0 | M5 | M6 | M8 | M10 | M12 | M14 | M16 | |||

| 16.0 | M5 | M6 | M8 | M10 | M12 | M14 | M16 | |||

| 2.0 | M3 | ||||||||

| 2.5 | M3 | |||||||||

| 3.0 | M3 | M4 | M5 | |||||||

| 4.0 | M3 | M4 | M5 | M6 | ||||||

| 5.0 | M3 | M4 | M5 | M6 | M8 | |||||

| 6.0 | M3 (*1) | M4 | M5 | M6 | M8 | |||||

| 9.0 | M5 | M6 | M8 | M10 | M12 | M14 | M16 | |||

| 10.0 | M5 | M6 | M8 | M10 | M12 | M14 | M16 | |||

| 12.0 | M5 | M6 | M8 | M10 | M12 | M14 | M16 | |||

| PET Acrylic Polycarbonate PVC | 3.0 | M3 | M4 | M5 | ||||||

| 5.0 | M3 | M4 | M5 | M6 | M8 | |||||

| 8.0 (*2) | M3 | M4 | M5 | M6 | M8 | M10 | ||||

| 10.0 (*3) | M3 | M4 | M5 | M6 | M8 | M10 | ||||

| Aluminum composite sheet (core material: foam polyethylene resin) *4 | 3.0 | M3 | M4 | M5 |

- *1 Only available for A5052 Aluminum Alloy.

- *2 Only available in PET (standard, transparent) OR Acrylic (standard, transparent)

- *3 Only available in Acrylic (standard, transparent)

- *4 Click here to see the countersink machining finish for aluminum composite sheets.