- HELP

- Technical Information

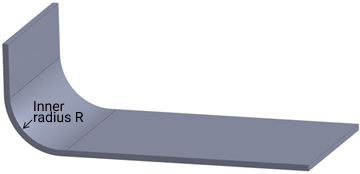

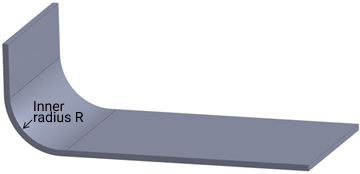

- Sheet metal

- Applicable parts/Materials

- Target Range for R-Bending (Large Radius)

Target Range for R-Bending (Large Radius)

Applicable sheet thickness and Radius size for R-bend shapes

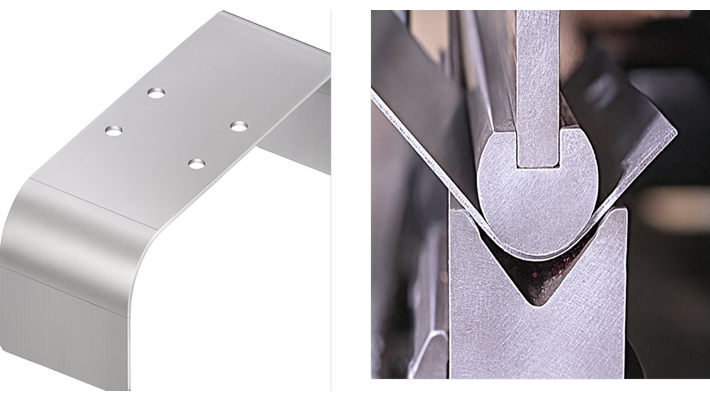

- R-bend shapes are generally manufactured using a feed bending process. This creates continuous tool marks that remain on the bent part. For details, please see “Bending Specifications“.

- If feed bending is difficult, we will propose radius sizes for which normal bending or special R-bend tools can be used. If this is acceptable, we will automatically change the R size on the meviy part.

- For details, please refer to the R-size conversion table below.

Metric Thickness - Inner R range

| Plate thickness | Minimum inner R | Maximum inner R |

|---|---|---|

| 0.8 | 10 | 150 |

| 1.0 | 10 | 150 |

| 1.2 | 10 | 150 |

| 1.5 | 10 | 150 |

| 1.6 | 10 | 150 |

| 2.0 | 10 * | 150 |

| 2.3 | 15 | 150 |

| 2.5 | 10 | 150 |

| 3.0 | 30 | 150 |

| 3.2 | 30 | 150 |

* Steel material is R15 as minimum inner R.

*R-size conversion table for when Feed bending is not possible.

| Inner R size before conversion | Inner R size after conversion | Bending process used |

|---|---|---|

| Within twice the sheet thickness | Thickness (reference value) | Normal Bending |

| Less than R3 | Thickness (reference value) | |

| R3 ≤ R < R6 | R3 | R-bending with special tools |

| R6 ≤ R < R10 | R6 | |

| R10 ≤ R < R12.5 | R10 | |

| R12.5 ≤ R < R15 | R12.5 | |

| R15 ≤ R < R17.5 | R15 | |

| R17.5 ≤ R < R20 | R17.5 | |

| R20 ≤ R < R22.5 | R20 | |

| R22.5 ≤ R < R25 | R22.5 | |

| R25 ≤ R < R30 | R25 | |

| R30 ≤ R |

| ー |

Inch Thickness - Inner R range

| Plate thickness | Minimum inner R | Maximum inner R |

|---|---|---|

| #24 | 0.394″ | 5.905″ |

| #22 | 0.394″ | 5.905″ |

| #20 | 0.394″ | 5.905″ |

| #19 | 0.394″ | 5.905″ |

| #18 | 0.394″ | 5.905″ |

| #16 | 0.394″ | 5.905″ |

| #14 | 0.394″ | 5.905″ |

| #13 | 0.394″ | 5.905″ |

| #12 | 0.394″ | 5.905″ |

| #11 | 0.181″ | 5.905″ |

Applicable materials and surface treatments for R-bend shapes

Materials and surface treatments available for R bending are as follows.

Metric Thickness Gauge Standard

| Material: Ferrous Metals | Surface Treatment | R bending available | |

|---|---|---|---|

| Feed Bending | R-bending with special tools | ||

| Low Carbon Steel (Cold/Hot Rolled) | – | Automatic Quotation | Automatic Quotation |

| Powder Coating | |||

| Wet Paint | |||

| Electroless Nickel Plating | |||

| Black Oxide | |||

| Trivalent Chromate (Clear) | |||

| Trivalent Chromate (Black) | Automatic Quotation | Manual Quotation | |

| Cold Rolled Low Carbon Steel (Electrolytic Zinc Plating) | Electrolytic Zinc Plating | Automatic Quotation | Automatic Quotation |

| Cold Rolled Low Carbon Steel (Galvanized) | Hot Zinc Plating | ||

| Material: Stainless Steel | Finishing Method | R bending available | |

|---|---|---|---|

| Feed Bending | R-bending with special tools | ||

| 304 Stainless Steel | 2B | Automatic Quotation | Automatic Quotation |

|

Manual Quotation | ||

|

Manual Quotation | Not supported | |

| 430 Stainless Steel | 2B | Automatic Quotation | Automatic Quotation |

| Material: Aluminum | Surface Treatment | R bending available | |

|---|---|---|---|

| Feed Bending | R-bending with special tools | ||

| 5052 Aluminum Alloy | — | Automatic Quotation | Automatic Quotation |

| Clear Anodize | |||

| Black Anodize | |||

| Black Anodize (matte) | |||

| Trivalent Chromate Passivation | |||

| 5052 AL Alloy Pre-Finish, Clear Anodize | Clear Anodize | ||

| 5052 AL Alloy Pre-Finish, Black Anodize | Black Anodize | ||

| Material: Perforated Metal | Hole Diameter × Hole Pitch | R bending available | |

|---|---|---|---|

| Feed Bending | R-bending with special tools | ||

| ø1 × 2p | Automatic Quotation | Automatic Quotation |

| ø2 × 3p | |||

| ø3 × 5p | |||

| ø5 × 8p | |||

| ø8 × 12p | |||

Inch Gauge Standard (FR bending only)

| Material: Ferrous Metals | Surface Treatment | Sheet Thickness (Inch) *1 | (mm) | External Dimensions *2 *4 | |||

|---|---|---|---|---|---|---|---|

| Length | Width | Height | |||||

|

Low Carbon Steel (Cold/Hot Rolled) |

– | 0.0299″ (#22), 0.0359″ (#20), 0.0418″ (#19), 0.0478″ (#18), 0.0538″ (#17), 0.0598″ (#16), 0.0747″ (#14), 0.0897″ (#13), 0.1046″ (#12), 0.1196″ (#11) | 0.759mm (#22), 0.912mm (#20), 1.062mm (#19), 1.214mm (#18), 1.367mm (#17), 1.519mm (#16), 1.897mm (#14), 2.278mm (#13), 2.657mm (#12), 3.038mm (#11) | 5–1500mm (59.05″) | |||

| Paint *3 | |||||||

| 5–1500mm (59.05″) | 5–1500mm (59.05″) | 5–1500mm (59.05″) | |||||

| Black Oxide | 5–609.6mm (24″) | 5–609.6mm (24″) | |||||

| Trivalent Chromate (Clear) | 5–1500mm (59.05″) | 5–584mm (23″) | 5–813mm (32″) | ||||

| Trivalent Chromate (Black) | |||||||

| Low Carbon Steel (Cold Rolled) | Electrolytic Galvanized *5 | 0.0336″ (#22), 0.0396″ (#20), 0.0516″ (#18), 0.0635″ (#16), 0.0785″ (#14) | 0.701mm (#24), 1.006mm (#20), 1.311mm (#18), 1.613mm (#16), 1.994mm (#14) | 5–1500mm (59.05″) | |||

| Hot Galvanized *5 | 0.0276″ (#24), 0.0336″ (#22), 0.0516″ (#18), 0.0635″ (#16), 0.0785″ (#14) | 0.701mm (#24), 0.853mm (#22), 1.311mm (#18), 1.613mm (#16), 1.994mm (#14) | 5–1500mm (59.05″) | ||||

| Material: Stainless Steel | Surface Finish | Sheet Thickness (Inch) *1 | (mm) | External Dimensions *2 *4 | |||

|---|---|---|---|---|---|---|---|

| Length | Width | Height | |||||

|

2B | 0.0312″ (#22), 0.0375″ (#20), 0.0437″ (#19), 0.0500″ (#18), 0.0625″ (#16), 0.0781″ (#14), 0.0937″ (#13), 0.1094″ (#12), 0.1250″ (#11) | 0.792mm (#22), 0.953mm (#20), 1.110mm (#19), 1.270mm (#18), 1.588mm (#16), 1.984mm (#14), 2.380mm (#13), 2.779mm (#12), 3.175mm (#11) | 5–1500mm (59.05″) | |||

| Single Sided #4 Brushed *6 | 0.0312″ (#22), 0.0375″ (#20), 0.0437″ (#19), 0.0500″ (#18), 0.0625″ (#16), 0.0781″ (#14), 0.0937″ (#13) | 0.792mm (#22), 0.953mm (#20), 1.110mm (#19), 1.270mm (#18), 1.588mm (#16), 1.984mm (#14), 2.380mm (#13) | |||||

| Material: Aluminum Alloy | Surface Treatment | Sheet Thickness (Inch) *1 | (mm) | External Dimensions *2 *4 | |||

|---|---|---|---|---|---|---|---|

| Length | Width | Height | |||||

| 5052 Aluminum Alloy | — | 0.025″, 0.032″, 0.040″, 0.050″, 0.063″, 0.080″, 0.090″, 0.100″, 0.125″ | 0.635mm, 0.813mm, 1.016mm, 1.270mm, 1.600mm, 2.032mm, 2.286mm, 2.540mm, 3.175mm | 5–1500mm (59.05″) | |||

| Anodize (Clear) | 5–914.4mm (36″) | 5–609.6mm (24″) | |||||

| Anodize (Black) | |||||||

- *1 The plate thickness tolerance is ±10% (reference value).

- *2 The maximum and minimum dimensional values are limited by the shape of the bend.

- *3 Select a paint color from the table (Appendix Table).

- *4 The maximum length and width dimensions (Appendix Table) may vary depending on the surface treatment.

- *5 The machining surface will not be plated as it is a pre-treatment material.

- *6 Protective sheets (one-side only) affixed.