- HELP

- Technical Information

- CNC Turning

- Accuracy and Machining Specifications

- Specifications for Male Thread, Female Thread, Keyways, Holes and Pockets

Specifications for Male Thread, Female Thread, Keyways, Holes and Pockets

Male and Female thread (mm)

The list of supported Male and Female thread is as follows.

Caution

Threads that are not listed in the specification table are not supported.Caution

- The automatic hole type recognition function is not available for the inner diameter in round object machining. You can configure the settings in the 3D Viewer

- CNC Turned parts Recognition Conditions

| 〇 | Male Thread and Female Thread available for Automatic quotation |

|---|---|

| ⚫️ | Tapped hole machined by MC available for Automatic quotation |

| △ |

|

| ✖ | Cannot be machined |

- *Female Thread: Threads machined on a lathe on the center axis

- *Tapped Hole: Threads machined by MC not on the center axis

- →CNC Turning > Design Guidelines > CNC Turned parts Recognition Conditions

| Nominal Diameter | Model Diameter (ø) mm | Pitch 1 | Male Thread | Female Thread・Tapped hole | Pitch 2 | Male Thread | Female Thread・Tapped hole | Pitch 3 | Male Thread | Female Thread・Tapped hole | Pitch 4 | Male Thread | Female Thread・Tapped hole | Pitch 5 | Male Thread | Female Thread・Tapped hole | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Male Thread | Female Thread | Right-Hand Thread | Left-Hand Thread | Right-Hand Thread | Left-Hand Thread | Right-Hand Thread | Left-Hand Thread | Right-Hand Thread | Left-Hand Thread | Right-Hand Thread | Left-Hand Thread | Right-Hand Thread | Left-Hand Thread | Right-Hand Thread | Left-Hand Thread | Right-Hand Thread | Left-Hand Thread | Right-Hand Thread | Left-Hand Thread | Right-Hand Thread | Left-Hand Thread | ||||||

| M2 | 1.7~2 | 1.5~2 | 0.4 | 〇 | 〇 | 〇⚫️ | 〇 | 0.25 | 〇 | △ | 〇⚫️ | △ | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M2.2 | 1.7~2.2 | 1.7~2.2 | 0.45 | 〇 | △ | 〇⚫️ | ✖ | 0.25 | 〇 | △ | 〇⚫️ | ✖ | |||||||||||||||

| M2.5 | 2.2~2.5 | 2~2.5 | 0.45 | 〇 | 〇 | 〇⚫️ | ✖ | 0.35 | 〇 | △ | 〇⚫️ | ✖ | |||||||||||||||

| M3 | 2.6~3 | 2.4~3 | 0.5 | 〇 | 〇 | 〇⚫️ | 〇 | 0.35 | 〇 | △ | 〇⚫️ | △ | |||||||||||||||

| M3.5 | 3.1~3.5 | 2.8~3.5 | 0.6 | 〇 | △ | 〇⚫️ | △ | 0.35 | 〇 | △ | 〇⚫️ | △ | |||||||||||||||

| M4 | 3.5~4 | 3.2~4 | 0.7 | 〇 | 〇 | 〇⚫️ | 〇 | 0.5 | 〇 | △ | 〇⚫️ | △ | |||||||||||||||

| M4.5 | 4~4.5 | 3.6~4.5 | 0.75 | 〇 | △ | 〇⚫️ | △ | 0.5 | 〇 | △ | 〇⚫️ | △ | |||||||||||||||

| M5 | 4.4~5 | 4.1~5 | 0.8 | 〇 | 〇 | 〇⚫️ | 〇 | 0.5 | 〇 | △ | 〇⚫️ | △ | |||||||||||||||

| M5.5 | 5.1~5.5 | 4.9~5.5 | 0.5 | 〇 | △ | 〇⚫️ | △ | ||||||||||||||||||||

| M6 | 5.3~6 | 4.9~6 | 1.0 | 〇 | 〇 | 〇⚫️ | 〇 | 0.75 | 〇 | 〇 | 〇⚫️ | 〇 | |||||||||||||||

| M7 | 6.3~7 | 5.9~7 | 1.0 | 〇 | △ | 〇⚫️ | △ | 0.75 | 〇 | △ | 〇⚫️ | ✖ | |||||||||||||||

| M8 | 7.1~8 | 6.6~8 | 1.25 | 〇 | 〇 | 〇⚫️ | 〇 | 1.0 | 〇 | 〇 | 〇⚫️ | 〇 | 0.75 | 〇 | △ | 〇⚫️ | △ | ||||||||||

| M9 | 8.1~9 | 7.6~9 | 1.25 | 〇 | △ | 〇⚫️ | △ | 1.0 | 〇 | △ | 〇⚫️ | △ | 0.75 | 〇 | △ | 〇⚫️ | ✖ | ||||||||||

| M10 | 9~10 | 8.3~10 | 1.5 | 〇 | 〇 | 〇⚫️ | 〇 | 1.25 | 〇 | △ | 〇⚫️ | 〇 | 1.0 | 〇 | △ | 〇⚫️ | 〇 | 0.75 | 〇 | △ | 〇⚫️ | △ | |||||

| M11 | 10~11 | 9.3~11 | 1.5 | 〇 | △ | 〇⚫️ | △ | 1.0 | 〇 | △ | 〇⚫️ | ✖ | 0.75 | 〇 | △ | 〇⚫️ | ✖ | ||||||||||

| M12 | 10.8~12 | 10.1~12 | 1.75 | 〇 | 〇 | 〇⚫️ | 〇 | 1.5 | 〇 | 〇 | 〇⚫️ | △ | 1.25 | 〇 | 〇 | 〇⚫️ | 〇 | 1.0 | 〇 | △ | 〇⚫️ | 〇 | |||||

| M14 | 12.7~14 | 11.8~14 | 2.0 | 〇 | 〇 | 〇⚫️ | 〇 | 1.5 | 〇 | 〇 | 〇⚫️ | 〇 | 1.25 | 〇 | △ | 〇⚫️ | △ | 1.0 | 〇 | △ | 〇⚫️ | △ | |||||

| M15 | 14~15 | 13.3~15 | 1.5 | 〇 | △ | 〇⚫️ | △ | 1.0 | 〇 | △ | 〇⚫️ | △ | |||||||||||||||

| M16 | 14.7~16 | 13.8~16 | 2.0 | 〇 | 〇 | 〇⚫️ | 〇 | 1.5 | 〇 | 〇 | 〇⚫️ | 〇 | 1.0 | 〇 | △ | 〇⚫️ | △ | ||||||||||

| M17 | 16~17 | 15.3~17 | 1.5 | 〇 | △ | 〇⚫️ | △ | 1.0 | 〇 | △ | 〇⚫️ | △ | |||||||||||||||

| M18 | 16.3~18 | 15.2~18 | 2.5 | 〇 | 〇 | 〇⚫️ | 〇 | 2.0 | 〇 | △ | 〇⚫️ | △ | 1.5 | 〇 | 〇 | 〇⚫️ | 〇 | 1.0 | △ | △ | 〇⚫️ | △ | |||||

| M20 | 18.3~20 | 17.2~20 | 2.5 | 〇 | 〇 | 〇⚫️ | 〇 | 2.0 | 〇 | △ | 〇⚫️ | △ | 1.5 | 〇 | 〇 | 〇⚫️ | 〇 | 1.0 | 〇 | △ | 〇⚫️ | △ | |||||

| Nominal Diameter | Model Diameter (ø) mm | Pitch 1 | Male Thread | Female Thread | Pitch 2 | Male Thread | Female Thread | Pitch 3 | Male Thread | Female Thread | Pitch 4 | Male Thread | Female Thread | Pitch 5 | Male Thread | Female Thread | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Male Thread | Female Thread | Right-Hand Thread | Left-Hand Thread | Right-Hand Thread | Left-Hand Thread | Right-Hand Thread | Left-Hand Thread | Right-Hand Thread | Left-Hand Thread | Right-Hand Thread | Left-Hand Thread | Right-Hand Thread | Left-Hand Thread | Right-Hand Thread | Left-Hand Thread | Right-Hand Thread | Left-Hand Thread | Right-Hand Thread | Left-Hand Thread | Right-Hand Thread | Left-Hand Thread | ||||||

| M22 | 20.3~22 | 19.2~22 | 2.5 | 〇 | 〇 | 〇 | 〇 | 2.0 | 〇 | △ | 〇 | △ | 1.5 | 〇 | 〇 | 〇 | 〇 | 1.0 | 〇 | △ | 〇 | △ | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M24 | 22~24 | 20.7~24 | 3.0 | 〇 | 〇 | 〇 | 〇 | 2.0 | 〇 | 〇 | 〇 | △ | 1.5 | 〇 | 〇 | 〇 | 〇 | 1.0 | 〇 | △ | 〇 | △ | |||||

| M25 | 23.7~25 | 22.8~25 | 2.0 | 〇 | △ | 〇 | △ | 1.5 | 〇 | △ | 〇 | △ | 1.0 | 〇 | 〇 | 〇 | △ | ||||||||||

| M26 | 25~26 | 24.3~26 | 1.5 | 〇 | △ | 〇 | △ | ||||||||||||||||||||

| M27 | 25~27 | 23.7~27 | 3.0 | 〇 | 〇 | 〇 | 〇 | 2.0 | 〇 | 〇 | 〇 | △ | 1.5 | 〇 | 〇 | 〇 | △ | 1.0 | 〇 | △ | 〇 | △ | |||||

| M28 | 26.7~28 | 25.8~28 | 2.0 | 〇 | △ | 〇 | △ | 1.5 | 〇 | △ | 〇 | △ | 1.0 | 〇 | △ | 〇 | △ | ||||||||||

| M30 | 27.7~30 | 26.2~30 | 3.5 | 〇 | 〇 | 〇 | 〇 | 3.0 | 〇 | △ | 〇 | △ | 2.0 | 〇 | 〇 | 〇 | △ | 1.5 | 〇 | 〇 | 〇 | 〇 | 1.0 | 〇 | △ | 〇 | △ |

| M32 | 30.7~32 | 29.8~32 | 2.0 | 〇 | △ | 〇 | △ | 1.5 | 〇 | △ | 〇 | △ | |||||||||||||||

| M33 | 30.7~33 | 29.2~33 | 3.5 | 〇 | 〇 | 〇 | 〇 | 3.0 | 〇 | △ | △ | △ | 2.0 | 〇 | 〇 | 〇 | △ | 1.5 | 〇 | △ | 〇 | △ | |||||

| M35 | 34~35 | 33.3~35 | 1.5 | 〇 | △ | 〇 | △ | ||||||||||||||||||||

| M36 | 33.4~36 | 31.6~36 | 4.0 | 〇 | 〇 | 〇 | 〇 | 3.0 | 〇 | △ | 〇 | △ | 2.0 | 〇 | 〇 | 〇 | 〇 | 1.5 | 〇 | △ | 〇 | △ | |||||

| M38 | 37~38 | 36.3~38 | 1.5 | 〇 | △ | 〇 | △ | ||||||||||||||||||||

| M39 | 36.4~39 | 34.6~39 | 4.0 | 〇 | 〇 | 〇 | 〇 | 3.0 | 〇 | △ | 〇 | △ | 2.0 | 〇 | △ | 〇 | △ | 1.5 | △ | 〇 | △ | △ | |||||

| M40 | 38~40 | 36.7~40 | 3.0 | 〇 | △ | △ | 〇 | 2.0 | 〇 | △ | 〇 | △ | 1.5 | 〇 | △ | 〇 | △ | ||||||||||

| M42 | 39~42 | 37.1~42 | 4.5 | 〇 | 〇 | 〇 | 〇 | 4.0 | 〇 | △ | △ | △ | 3.0 | 〇 | 〇 | 〇 | △ | 2.0 | 〇 | △ | 〇 | △ | 1.5 | △ | △ | 〇 | △ |

| M45 | 42~45 | 40.1~45 | 4.5 | 〇 | △ | 〇 | 〇 | 4.0 | △ | △ | △ | △ | 3.0 | 〇 | △ | 〇 | △ | 2.0 | 〇 | △ | 〇 | △ | 1.5 | 〇 | △ | 〇 | △ |

| M48 | 44.7~48 | 42.5~48 | 5.0 | 〇 | 〇 | 〇 | 〇 | 4.0 | △ | △ | △ | △ | 3.0 | 〇 | △ | 〇 | △ | 2.0 | 〇 | 〇 | 〇 | △ | 1.5 | 〇 | △ | 〇 | △ |

| M50 | 48~50 | 46.7~50 | 3.0 | △ | △ | △ | △ | 2.0 | △ | △ | △ | △ | 1.5 | △ | △ | 〇 | △ | ||||||||||

Notes

The automatic hole type recognition function is supported in the same way as for edged object machining.Male and Female thread (inch)

The list of supported Male and Female thread is as follows.

For inch threads, only right-hand threads are available.

“Display style” drop down menu in the upper right of model viewer can be set to “Unit(inch)” to display all model units in inches.

For all threads, the thread depth will be entered in mm. The inch value will be shown for reference.

| ◯ | Male Thread and Female Thread available for Automatic quotation |

|---|---|

| ⚫️ | Tapped hole machined by MC available for Automatic quotation |

| △ |

|

| ✖ | Cannot be machined |

| Nominal Diameter | Model Diameter (ø) mm | Thread Type | Male Thread | Female Thread | ||

|---|---|---|---|---|---|---|

| Male Thread / Female Thread | Right-Hand Thread | Left-Hand Thread | Right-Hand Thread | Left-Hand Thread | ||

| #2-56 | 1.96~2.19 | UNC | ◯ | ✖ | ◯⚫️ | ✖ |

|---|---|---|---|---|---|---|

| #2-64 | 1.75~2.19 | UNF | ◯ | ✖ | ◯⚫️ | ✖ |

| #3-48 | 1.94~2.52 | UNC | ◯ | ✖ | ◯⚫️ | ✖ |

| #3-56 | 2.02~2.52 | UNF | ◯ | ✖ | ◯⚫️ | ✖ |

| #4-40 | 2.15~2.85 | UNC | ◯ | ✖ | ◯⚫️ | ✖ |

| #4-48 | 2.12~2.85 | UNF | ◯ | ✖ | ◯⚫️ | ✖ |

| #5-40 | 2.48~3.18 | UNC | ◯ | ✖ | ◯⚫️ | ✖ |

| #5-44 | 2.55~3.18 | UNF | ◯ | ✖ | ◯⚫️ | ✖ |

| #6-32 | 2.64~3.51 | UNC | ◯ | ✖ | ◯⚫️ | ✖ |

| #6-40 | 2.81~3.51 | UNF | ◯ | ✖ | ◯⚫️ | ✖ |

| #8-32 | 3.3~4.17 | UNC | ◯ | ✖ | ◯⚫️ | ✖ |

| #8-36 | 3.4~4.17 | UNF | ◯ | ✖ | ◯⚫️ | ✖ |

| #10-24 | 3.68~4.83 | UNC | ◯ | ✖ | ◯⚫️ | ✖ |

| #10-32 | 3.96~4.83 | UNF | ◯ | ✖ | ◯⚫️ | ✖ |

| #12-24 | 4.34~5.49 | UNC | ◯ | ✖ | ◯⚫️ | ✖ |

| #12-28 | 4.49~5.49 | UNF | ◯ | ✖ | ◯⚫️ | ✖ |

| 1/4-20 | 4.97~6.35 | UNC | ◯ | ✖ | ◯⚫️ | ✖ |

| 1/4-28 | 5.35~6.35 | UNF | ◯ | ✖ | ◯⚫️ | ✖ |

| 5/16-18 | 6.4~7.94 | UNC | ◯ | ✖ | ◯⚫️ | ✖ |

| 5/16-24 | 6.78~7.94 | UNF | ◯ | ✖ | ◯⚫️ | ✖ |

| 3/8-16 | 7.79~9.53 | UNC | ◯ | ✖ | ◯⚫️ | ✖ |

| 3/8-24 | 8.37~9.53 | UNF | ◯ | ✖ | ◯⚫️ | ✖ |

| 7/16-14 | 9.14~11.12 | UNC | ◯ | ✖ | ◯⚫️ | ✖ |

| 7/16-20 | 9.72~11.12 | UNF | ◯ | ✖ | ◯⚫️ | ✖ |

| 1/2-13 | 10.58~12.7 | UNC | ◯ | ✖ | ◯⚫️ | ✖ |

| 1/2-20 | 11.32~12.7 | UNF | ◯ | ✖ | ◯⚫️ | ✖ |

| 9/16-12 | 11.98~14.29 | UNC | ◯ | ✖ | ◯⚫️ | ✖ |

| 9/16-18 | 12.75~14.29 | UNF | ◯ | ✖ | ◯⚫️ | ✖ |

| 5/8-11 | 13.37~15.88 | UNC | ◯ | ✖ | ◯⚫️ | ✖ |

| 5/8ー18 | 14.27~15.88 | UNF | ◯ | ✖ | ◯⚫️ | ✖ |

| 3/4-10 | 16.29~19.05 | UNC | ◯ | ✖ | ◯ | ✖ |

| 3/4-16 | 17.32~19.05 | UNF | ◯ | ✖ | ◯ | ✖ |

| 1-8 | 21.96~25.4 | UNC | ◯ | ✖ | ◯ | ✖ |

| 1-12 | 23.11~25.4 | UNF | ◯ | ✖ | ◯ | ✖ |

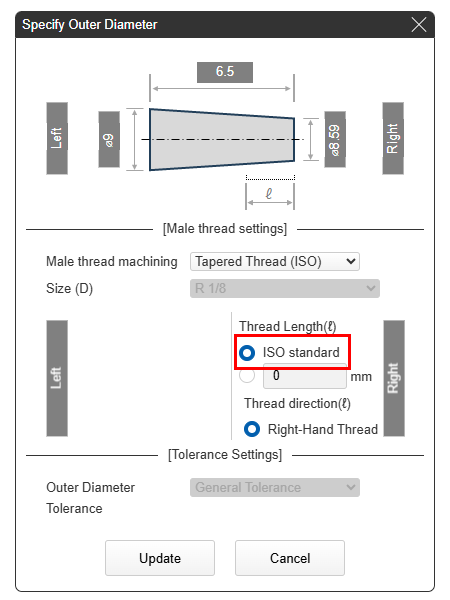

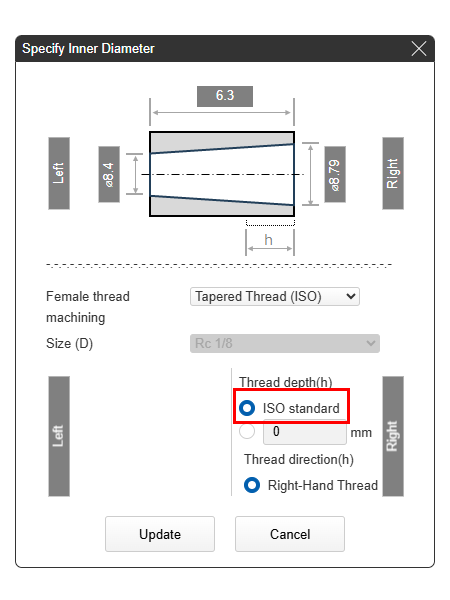

Tapered Male and Female thread (ISO)

- The following is a list of available tapered pipe thread sizes.

- G (parallel pipe thread), Rp (parallel female tapered pipe thread), etc. are not available.

| ◯ | automatic quoting available |

|---|---|

| ✖ | Cannot be machined(Manual quotation) |

| Nominal diameter | Model Diameter | ISO Standard Effective Length | Male Thread | Nominal diameter | Model Diameter | ISO Standard Effective Depth | Female Thread | |

|---|---|---|---|---|---|---|---|---|

| With incomplete threads | Only with complete threads | |||||||

| R1/16 | 5.44~8.01 | 6.4 | 〇 | Rc1/16 | 5.44~8.07 | 6.2 | 4.4 | 〇 |

| R1/8 | 8.02~10.42 | 6.4 | 〇 | Rc 1/8 | 8.08~10.49 | 6.2 | 4.4 | 〇 |

| R1/4 | 10.43~13.85 | 9.7 | 〇 | Rc 1/4 | 10.5~13.97 | 9.4 | 6.7 | 〇 |

| R3/8 | 13.86~17.41 | 10.0 | 〇 | Rc 3/8 | 13.98~17.52 | 9.7 | 7.0 | 〇 |

| R1/2 | 17.42~21.70 | 13.1 | 〇 | Rc 1/2 | 17.53~21.96 | 12.7 | 9.1 | 〇 |

| R3/4 | 22.82~27.14 | 14.5 | 〇 | Rc 3/4 | 22.97~27.44 | 14.1 | 10.2 | 〇 |

| R1 | 28.97~33.92 | 16.7 | 〇 | Rc 1 | 29~34.25 | 16.2 | 11.6 | 〇 |

| R11/4 | 37.56~42.51 | 19.1 | 〇 | Rc 11/4 | 37.81~42.91 | 18.5 | 13.4 | 〇 |

| R11/2 | 43.45~48.41 | 19.1 | 〇 | Rc 11/2 | 43.7~48.8 | 18.5 | 13.4 | 〇 |

| R2 | 55.16~60.12 | 23.3 | × | Rc 2 | 55.66~60.61 | 22.8 | 16.9 | × |

| R2 1/2 | 70.68~75.64 | 26.6 | × | Rc 2 1/2 | 71.23~76.18 | 26.7 | 18.6 | × |

| R3 | 83.28~88.24 | 29.8 | × | Rc 3 | 83.93~89.1 | 29.8 | 21.1 | × |

| R4 | 107.08~112.04 | 35.8 | × | Rc4 | 109.15~114.63 | 35.8 | 25.9 | × |

| R5 | 132.21~137.17 | 40.0 | × | Rc 5 | 134.47~140.5 | 40.1 | 29.3 | × |

| R6 | 157.61~162.57 | 40.0 | × | Rc 6 | 159.87~166.0 | 40.1 | 29.3 | × |

Tip

Thread length is automatically quoted using ISO standard lengths. Tapered pipe threads must pass a gauge inspection before the product is shipped.

Please request a Manual Quotation if a length other than the standard is required.

Caution

Model the taper into the part. The angle for tapered pipe threads can be specified between 0° and 2.5° with respect to the center axis.

Caution

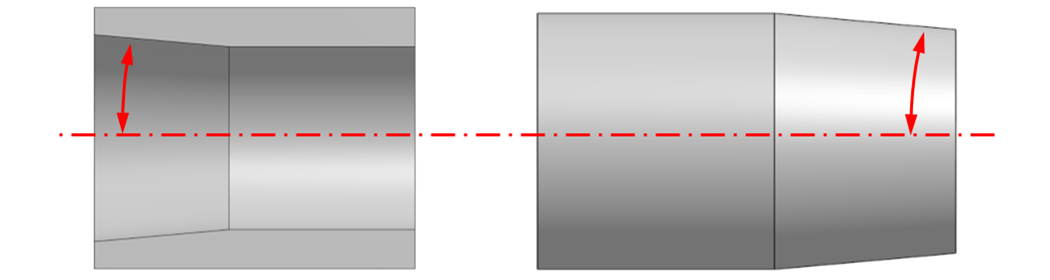

The diameter of the taper in the model is determined as shown in the figure below for Male and Female Threads. The diameter sizes recognized by meviy follow ISO standards.

(Reference) Tapered Pipe Threads (Excerpt from JIS B 0203:1999)

Insert Holes

- Inserts can be specified when the selected material is Aluminum or Resin. The settings for insert holes can be set to select inserts using the same logic as the female thread recognition for CNC Turning.

- The insert material is 304 Stainless Steel.

- There are four nominal lengths for each diameter: 0.5D, 1D, 1.5D and 2D.

- Inch threads are not available.

[mm]

| Insert | Pitch |

|---|---|

| Nominal Diameter | |

| M2 | 0.4 |

| M2.5 | 0.45 |

| M3 | 0.5 |

| M4 | 0.7 |

| M5 | 0.8 |

| M6 | 1.0 |

| M8 | 1.25 |

| M10 | 1.5 |

| M12 | 1.75 |

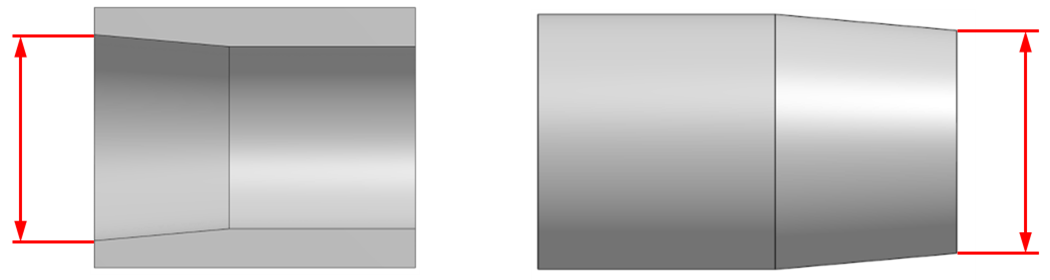

Keyways

For keyways that match the JIS (B 1301:1996), tolerances are automatically set and can be changed in the dialog.

*The default settings can be customised in user settings.

[mm]

| b1 and b2 Key Dimensions | b1 Tolerance | b2 Tolerance | t1 Key Dimensions | t1 Tolerance | t2 Key Dimensions | t2 Tolerance | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| P9 | N9 | H9 | P9 | Js9 | D10 | |||||

| 2 |

|

|

|

|

±0.0125 |

|

1.2 |

|

1.0 |

|

| 3 | 1.8 | 1.4 | ||||||||

| 4 |

|

|

|

|

±0.0150 |

|

2.5 | 1.8 | ||

| 5 | 3.0 | 2.3 | ||||||||

| 6 | 3.5 | 2.8 | ||||||||

| 8 |

|

|

|

|

±0.0180 |

|

4.0 |

|

3.3 |

|

| 10 | 5.0 | |||||||||

| 12 |

|

|

|

|

±0.0215 |

|

||||

| 14 | 5.5 | 3.8 | ||||||||

| 16 | 6.0 | 4.3 | ||||||||

| 18 | 7.0 | 4.4 | ||||||||

| 20 |

|

|

|

|

±0.0260 |

|

7.5 | 4.9 | ||

| 22 | 9.0 | 5.4 | ||||||||

| 25 | ||||||||||

| 28 | 10 | 6.4 | ||||||||

| 32 |

|

|

|

-0.026 -0.088 | ±0.0310 |

|

11 | 7.4 | ||

Precision Hole

- Precision holes are straight holes with either a fit tolerance, a bidirectional tolerance, or a unidirectional tolerance selected for the hole diameter tolerance.

- The accuracy and effective depth for the diameter can be specified with precision holes.

Accuracy ranges supported for automatic quotation

[mm]

| Diameter | Accuracy Range | |||

|---|---|---|---|---|

| > | ≤ | Fit Tolerance | Both-Side Tolerance Minimum Value | One-Side Tolerance Minimum Value (Range) |

| 2.999 | 3 | Grade IT7 or higher | 0.005 | 0.01 |

| 3 | 6 | 0.006 | 0.012 | |

| 6 | 10 | 0.008 | 0.015 | |

| 10 | 18 | 0.009 | 0.018 | |

| 18 | 30 | 0.011 | 0.021 | |

| 30 | 50 | 0.013 | 0.025 | |

| 50 | 80 | 0.015 | 0.03 | |

| 80 | 120 | 0.018 | 0.035 | |

| 120 | 180 | 0.02 | 0.04 | |

| 180 | 250 | 0.023 | 0.046 | |

| 250 | 315 | 0.026 | 0.052 | |

| 315 | 400 | 0.029 | 0.057 | |

| 400 | 500 | 0.032 | 0.063 | |

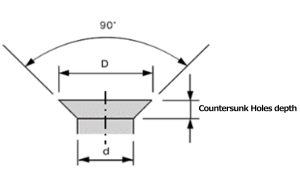

Countersunk Holes

Holes with the following shapes on the right and left end faces are recognised as countersunk holes.

- *Countersunk hole shapes modelled on the cylinder side are not recognised as countersunk holes.

- ・ Countersunk (on a conical shape) angle is 90°

- ・d is 3.0 mm or more

- ・D/d: When d ≧ 4.0 mm, D > 1.4 d

- When d < 4.0 mm, D > 1.7 d

Pockets and Slotted Holes

Compatible range of pockets and slots

| Shape type | No tolerance | Tolerance range | |

|---|---|---|---|

| 0.1~(±0.05~) | 0.04~(±0.02~) | ||

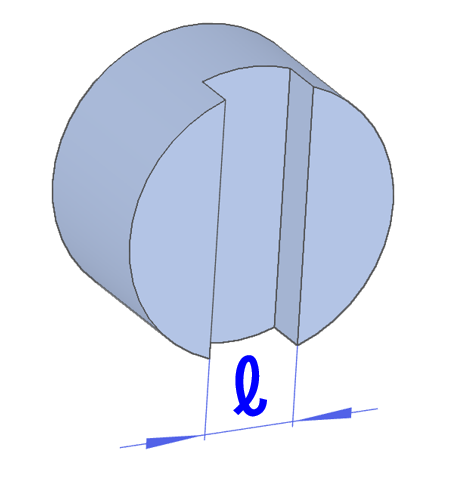

|

ℓ ≥ 0.5mm | ℓ ≥ 0.5mm | ー |

|

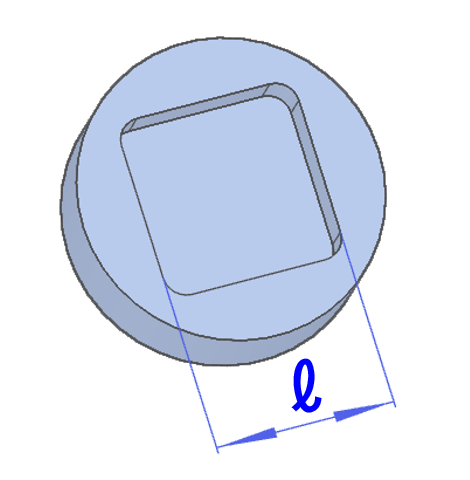

ℓ ≥ 2mm | ℓ ≥ 2mm | ℓ ≥ 2mm |

|

ℓ ≥ 2mm | ℓ ≥ 2mm | ℓ ≥ 3mm |

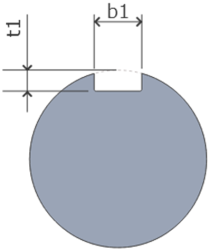

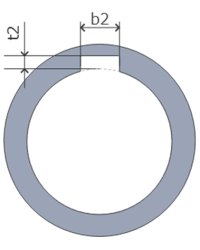

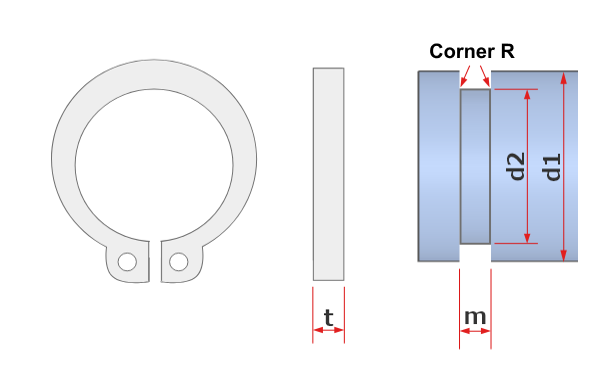

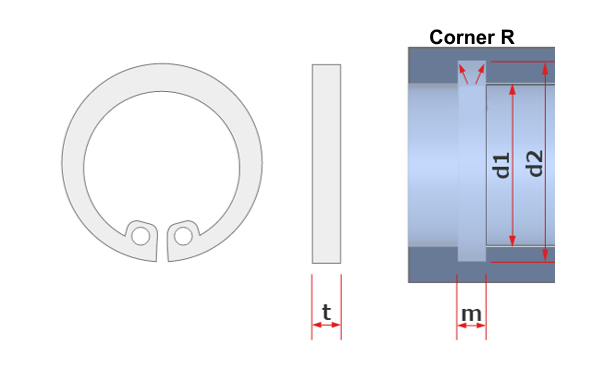

Retaining ring

Required groove width for retaining rings

Retaining ring – External, C-Type

Applicable axis

Retaining ring – Internal, C-Type

Applicable grooving

| Reference values for C-Type retaining ring “t,” “m,” and “Corner R” | ||

|---|---|---|

| t: Retaining ring width | m: Required groove width | Corner R |

| 1 | 1.15 | R0.1 or less |

| 1.25 | 1.35 | |

| 1.5 | 1.65 | R0.15 or less |

| 1.75 | 1.9 | |

| 2 | 2.2 | R0.2 or less |

| 2.5 | 2.7 | |

| 3 | 3.2 | |

| 4 | 4.2 | |

Notes

- It is recommended that diameters d1 and d2 are designed to meet the standard for C-type retaining rings.

- *E-type rings for small diameters are not available