- HELP

- Technical Information

- Welded Sheet Metal

- Design Guidelines

- Range of Machining Limits

Range of Machining Limits

- Meviy Welded Sheet Metal Service determines the machinability of welded areas and component parts within products.

- Refer to the table below for machinability limits or dimensional ranges of welded areas within products.

- For machining limits of component parts, refer to the sheet metal part design guideline “Range of Machining Limits“.

- However, since the machining limits for components in the Welded Sheet Metal Service differ from those for some sheet metal parts, they are listed in the table below.

- *Values may differ from those listed depending on surface treatment, shape, and processing conditions.

- *When two or more plate thicknesses are present, the threshold for the thickest plate thickness is applied to the entire product to determine machinability.

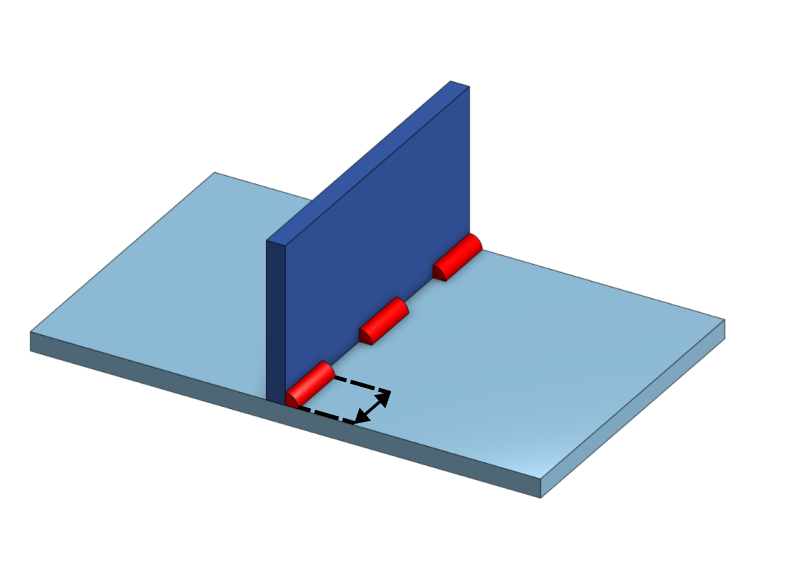

Minimum Weld Length

Processing Limit/Dimension Range

| Sheet Thickness | Limit Value | |

|---|---|---|

| Standard (arc or laser) | Arc Welding |

| 1.0 | 1.0 | |

| 1.2 | ||

| 1.6 | ||

| 2.0 | 2.0 | |

| 2.3 | ||

| 3.2 | 3.0 | |

| 4.5 | 5.0 | |

| 6.0 | ||

| 9.0 | 10.0 | |

| 10.0 | ||

| 12.0 | ||

| 16.0 | ||

| Sheet Thickness | Limit Value | |

|---|---|---|

|

Standard (Arc or Laser) | Arc Welding |

| 1.0 | 3.0 | 1.0 |

| 1.2 | ||

| 1.5 | ||

| 2.0 | 2.0 | |

| 2.5 | ||

| 3.0 | 3.0 | |

| 4.0 | 10.0 | |

| 5.0 | ||

| 6.0 | ||

| 9.0 | 10.0 | |

| 10.0 | ||

| 12.0 | ||

| Sheet Thickness | Limit value | |

|---|---|---|

| 304 SS (#400) | Standard (arc or laser) | Arc welding |

| 1.0 | 1.0 | |

| 1.2 | ||

| 1.5 | ||

| 2.0 | 2.0 | |

| 3.0 | 3.0 | |

| Sheet Thickness | Limit Value | |

|---|---|---|

| 5052 Aluminum Alloy | Standard (arc or laser) | Arc welding |

| 1.0 | 5.0 | |

| 1.2 | ||

| 1.5 | ||

| 1.6 | ||

| 2.0 | 10.0 | |

| 2.5 | ||

| 3.0 | ||

| 4.0 | 15.0 | |

| 5.0 | 20.0 | |

| 6.0 | ||

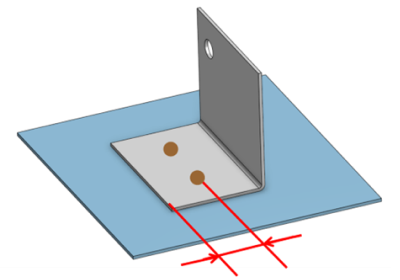

Part Examples

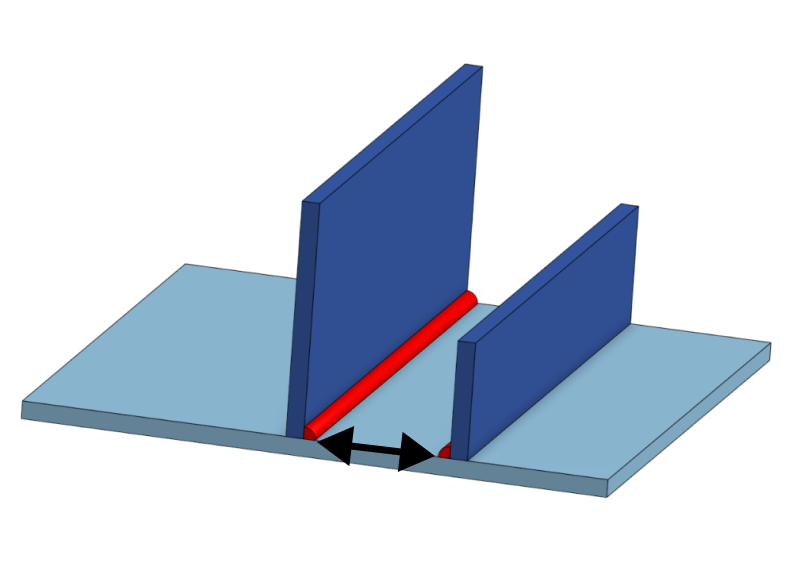

Minimum distance between flat welds

Processing limits/dimension range

| Sheet Thickness | Guaranteed Value | |

|---|---|---|

| Standard (arc or laser) | Arc Welding |

| 1.0 | 4.0 | |

| 1.2 | 4.5 | |

| 1.6 | ||

| 2.0 | 5.0 | |

| 2.3 | ||

| 3.2 | ||

| 4.5 | 6.0 | |

| 6.0 | 7.0 | |

| 9.0 | ||

| 10.0 | 10.0 | |

| 12.0 | ||

| 16.0 | ||

| Sheet Thickness | Guaranteed Value | |

|---|---|---|

|

Standard (Arc or Laser) | Arc Welding |

| 1.0 | 3.0 | 4.0 |

| 1.2 | 4.5 | |

| 1.5 | ||

| 2.0 | 5.0 | |

| 2.5 | ||

| 3.0 | ||

| 4.0 | 6.0 | |

| 5.0 | 7.0 | |

| 6.0 | 8.0 | |

| 9.0 | 10.0 | 10.0 |

| 10.0 | ||

| 12.0 | ||

| Sheet Thickness | Guaranteed Value | |

|---|---|---|

| 304 SS (#400) | Standard (arc or laser) | Arc welding |

| 1.0 | 4.0 | |

| 1.2 | 4.5 | |

| 1.5 | ||

| 2.0 | 5.0 | |

| 3.0 | ||

| Sheet Thickness | Guaranteed Value | |

|---|---|---|

| 5052 Aluminum Alloy | Standard (arc or laser) | Arc Welding |

| 1.0 | 20.0 | |

| 1.2 | ||

| 1.5 | ||

| 1.6 | ||

| 2.0 | ||

| 2.5 | 25.0 | |

| 3.0 | 30.0 | |

| 4.0 | ||

| 5.0 | ||

| 6.0 | ||

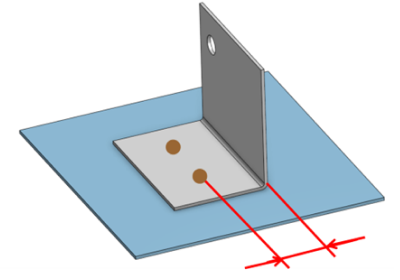

Example locations

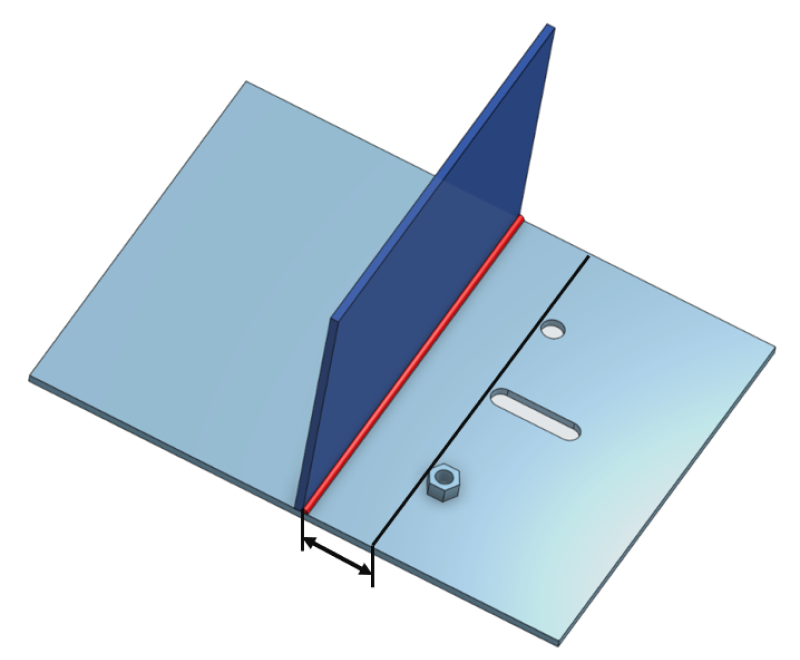

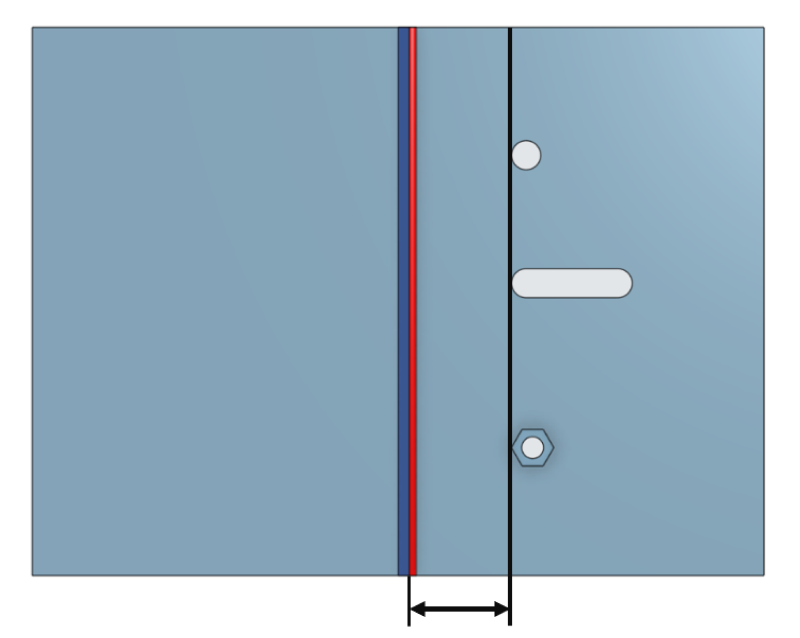

Minimum Distance Between Welded Areas and Various Holes

Processing limits/dimension range

| Sheet Thickness | Limit Value | |

|---|---|---|

| Standard (arc or laser) | Arc Welding |

| 1.0 | 5.0 | |

| 1.2 | ||

| 1.6 | ||

| 2.0 | 6.0 | |

| 2.3 | ||

| 3.2 | ||

| 4.5 | 8.0 | |

| 6.0 | 10.0 | |

| 9.0 | ||

| 10.0 | ||

| 12.0 | ||

| 16.0 | 12.0 | |

*Due to manufacturing constraints, for certain iron-based painted products (T Cream (approximate Munsell 10GY9/1) and trivalent chromate (black)), press-fit nuts will be quoted by Manual Quote.

| Sheet Thickness | Limit Value | |

|---|---|---|

|

Standard (arc or laser) | Arc Welding |

| 1.0 | 3.0 | 5.0 |

| 1.2 | ||

| 1.5 | ||

| 2.0 | 6.0 | |

| 2.5 | ||

| 3.0 | ||

| 4.0 | 4.0 | 8.0 |

| 5.0 | 5.0 | 10.0 |

| 6.0 | 6.0 | 12.0 |

| 9.0 | 10.0 | 10.0 |

| 10.0 | ||

| 12.0 | ||

| Sheet thickness | Limit value | |

|---|---|---|

| 304 SS (#400) | Standard (arc or laser) | Arc welding |

| 1.0 | 5.0 | |

| 1.2 | ||

| 1.5 | ||

| 2.0 | 6.0 | |

| 3.0 | ||

| Sheet thickness | Limit value | |

|---|---|---|

| 5052 Aluminum Alloy | Standard (arc or laser) | Arc Welding |

| 1.0 | 10.0 | 15.0 |

| 1.2 | ||

| 1.5 | ||

| 1.6 | ||

| 2.0 | 20.0 | |

| 2.5 | ||

| 3.0 | 25.0 | |

| 4.0 | 30.0 | |

| 5.0 | ||

| 6.0 | ||

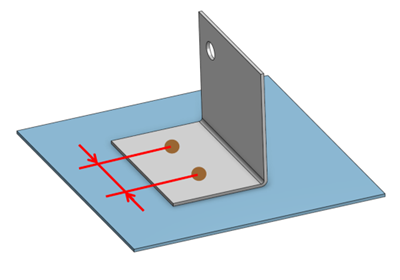

Example of location

Minimum distance between spot weld and hole/plate edge

| Sheet thickness | Limit value |

|---|---|

| Low Carbon Steel (Cold/Hot) | |

| 1.0 | 5.0 |

| 1.2 | 5.0 |

| 1.6 | 5.0 |

| 2.0 | 7.5 |

| 2.3 | 10.0 |

| 3.2 | 10.0 |

| Sheet thickness | Limit value |

|---|---|

| Low Carbon Steel (Electrolytic Zinc Plating) | |

| 1.0 | 10.0 |

| 1.2 | 10.0 |

| 1.6 | 10.0 |

| 2.0 | 10.6 |

| 2.3 | 11.5 |

| 3.2 | 13.2 |

| Sheet thickness | Limit value |

|---|---|

|

|

| 1.0 | 6.0 |

| 1.2 | 6.0 |

| 1.5 | 7.0 |

| 2.0 | 9.0 |

| 2.5 | 10.0 |

| 3.0 | 11.0 |

| Sheet Thickness | Limit value |

|---|---|

| 5052 Aluminum Alloy | |

| 1.0 | 8.0 |

| 1.2 | 9.0 |

| 1.5 | 10.0 |

| 1.6 | 10.0 |

| 2.0 | 11.0 |

| 2.5 | 12.0 |

Minimum distance from spot weld to bend

| Sheet thickness | Limit value |

|---|---|

| Low Carbon Steel (Cold/Hot) | |

| 1.0 | 10.0 |

| 1.2 | 10.4 |

| 1.6 | 11.2 |

| 2.0 | 12.0 |

| 2.3 | 14.6 |

| 3.2 | 16.4 |

| Sheet thickness | Limit value |

|---|---|

| Low Carbon Steel (Electrolytic Zinc Plating) | |

| 1.0 | 11.0 |

| 1.2 | 11.2 |

| 1.6 | 11.6 |

| 2.0 | 12.0 |

| 2.3 | 14.6 |

| 3.2 | 16.4 |

| Sheet thickness | Limit value |

|---|---|

|

|

| 1.0 | 8.0 |

| 1.2 | 8.4 |

| 1.5 | 10.0 |

| 2.0 | 13.0 |

| 2.5 | 15.0 |

| 3.0 | 16.0 |

| Sheet thickness | Limit value |

|---|---|

| 5052 Aluminum Alloy | |

| 1.0 | 12.0 |

| 1.2 | 12.4 |

| 1.5 | 13.0 |

| 1.6 | 13.2 |

| 2.0 | 15.0 |

| 2.5 | 15.0 |

Minimum distance between spot welds

| Sheet thickness | Limit value |

|---|---|

|

|

| 1.0 | 15.0 |

| 1.2 | 17.0 |

| 1.6 | 19.0 |

| 2.0 | 21.0 |

| 2.3 | 23.0 |

| 3.2 | 27.0 |

| Sheet thickness | Limit value |

|---|---|

|

|

| 1.0 | 15.0 |

| 1.2 | 17.0 |

| 1.5 | 19.0 |

| 2.0 | 21.0 |

| 2.5 | 25.0 |

| 3.0 | 27.0 |

| Sheet thickness | Limit value |

|---|---|

| 5052 Aluminum Alloy | |

| 1.0 | 20.0 |

| 1.2 | 22.0 |

| 1.5 | 25.0 |

| 1.6 | 25.0 |

| 2.0 | 28.0 |

| 2.5 | 32.0 |

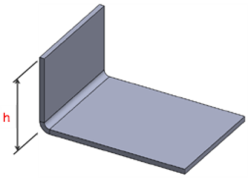

Minimum bend height: Standard bending process

Processing limits/dimension range

| Material | Sheet Thickness | Limit Value h |

|---|---|---|

| Low Carbon Steel (Hot Rolled) | 9.0 | 40.0 |

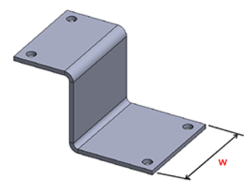

Part Examples

Bending width dimension specification range

Processing limits/dimension range

| Material | Sheet Thickness | Dimension Range w |

|---|---|---|

| Low Carbon Steel (Hot Rolled) | 9.0 | 10 to 500 |

| 304 SS (2B) *1 | 5.0 | 10 to 850 |

Part Examples

Minimum angle for sharp bends

Processing Limits and Dimensional Range

- The angle θ f o r sharp bends must be 45° or greater.

- However, for Welded Sheet Metal services, the θrequirement differs only for the following materials and sheet thicknesses.

| Material | Surface Treatment | Sheet Thickness | Sharp bend angle |

|---|---|---|---|

| 5052 Aluminum Alloy | None | 1.0 1.2 1.5 1.6 2.0 2.5 3.0 4.0 5.0 6.0 | θ ≥ 90 |

| Anodized (White) | |||

| Anodized (Black) | |||

| Anodized (Matte Black) | |||

| Low Carbon Steel *1 | None | 1.6 2.0 2.3 | |

| Electroless Nickel Plating | |||

| Trivalent Chromate (Clear) | |||

| 304 SS (2B) *1 | – | 1.5 2.0 2.5 3.0 4.0 5.0 | |

| 430 SS (2B) *1 | – | 1.5 2.0 3.0 |

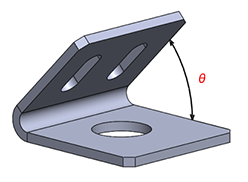

Part Examples

*1 Due to factory processing constraints, restrictions apply only to long lead time services. If you cannot select a long lead time quote despite being within the applicable range, please contact meviy support.