- HELP

- Technical Information

- Welded Sheet Metal

- Welding Standards

- Welding Processing Standards

Welding Processing Standards

Welding Type

Arc Welding

Welding type “Arc Welding” shall be performed using TIG welding or Semi-automatic welding (CO2 welding).

Additionally, welding shall be performed using welding rods as necessary.

The decision on which welding method to use for fabrication shall be made at the manufacturing plant, referring to the standards described later, based on the product shape.

- This method is primarily used for thin plates, the outer edges of box shapes, and butt welds. For medium-thickness plates and above, TIG welding may also be performed using welding rods.

- The TIG welded area exhibits a continuous, overlapping scale-like appearance.

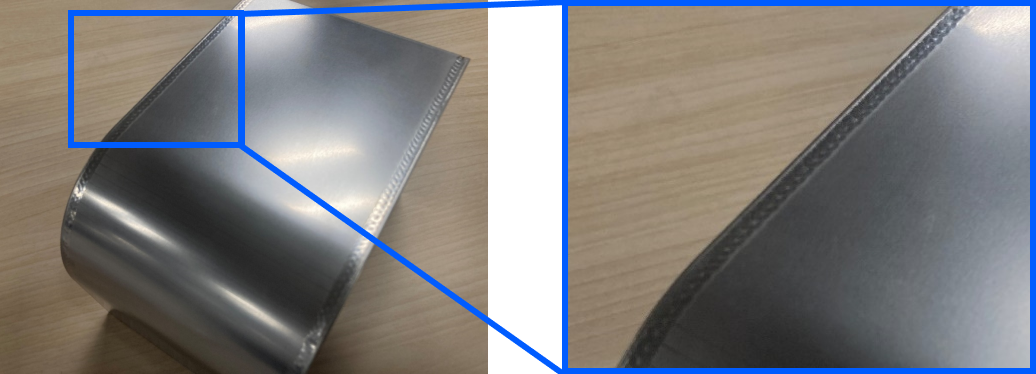

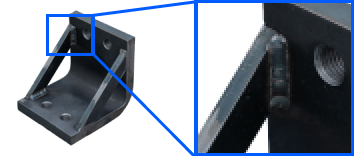

Example of TIG welded fabrication (without filler rod, 304 Stainless Steel (2B))

- This welding method is often used for medium-thickness plate products with fillet welds. It tends to produce spatter and slag during processing.

- The welded area is built up, resulting in a more prominent appearance compared to TIG welding.

Example of CO2 welding (with filler rod, Low Carbon Steel (Hot Rolled))

- Used when performing arc welding on iron-based materials with plate thicknesses of 3.2mm or greater, SUS-based materials with plate thicknesses of 4.0mm or greater, and aluminum materials with plate thicknesses of 2.0mm or greater.

- However, for areas such as the outer perimeter of box shapes, butt welds, or locations where the weld bead may interfere with holes when using a filler rod, TIG welding may be used instead without a filler rod to prioritize appearance and functionality.

Example of weld repair using TIG welding (with filler rod, A5052)

Laser Welding

Laser welding is performed using either fiber laser welding or YAG laser welding.

The manufacturing plant determines which method to use based on the product shape.

Example of laser welding processing

Standard (Arc or Laser)

For “Leave it to us (Arc or Laser)”, welding is performed using the welding methods described above for arc welding or laser welding, and the product is shipped.

The type of welding used during production is determined at the manufacturing plant based on conditions such as the requested material, plate thickness, and product shape.

For repeat orders of the same model number, welding will be performed using the same method as the initial order.

Spot Welding

For spot welding, we use either fixed-position or table-type spot welding machines depending on the product shape. The machine type is determined at the manufacturing plant.

- Processing is performed using either fixed-type or table-type spot welding machines.

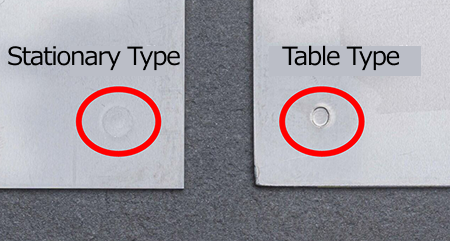

- The spot weld marks differ: with fixed-type machines, indentations form on both sides of the overlapping area of the two plates as spot marks. With table-type machines, no indentations form on the surface placed flat against the table electrode.

- While appearance also varies depending on material, plate thickness, and shape, the depth of the indentation tends to be greater with the table-type method.

Spot Weld Mark Examples by Welding Method Material

Example: 304 Stainless Steel (2B)

- The pressure direction during spot welding is determined at the manufacturing plant based on the product shape.

- If you wish to specify the processing method, please indicate it in the Additional Instructions section and request a quote from the responsible person.

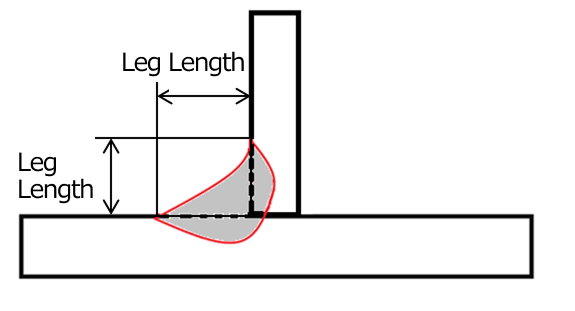

Weld leg length

For products welded using arc welding, the target leg length is as follows.

If you require welding with leg lengths outside the ranges below, please specify this in the Additional Instructions field and request a quote from meviy Support.

・Low Carbon Steel (Cold/Hot Rolled), Low Carbon Steel (Cold Rolled) (Electrolytic Zinc Plating), 304 Stainless Steel (2B), 304 Stainless Steel (No.1), Stainless Steel (Single-sided hairline finish), 430 Stainless Steel (2B)

- – Reference value (minimum): 0.7 x plate thickness t1 mm

- – Maximum Value: 1.5 x Plate Thickness t2 mm

- *For welding plates of different thicknesses

- Plate thickness t1: Thinner plate thickness, Plate thickness t2: Thicker plate thickness

- – Reference value (minimum): 3.5 mm

- – Maximum value: 10 mm

Strength of welded products

We do not guarantee the strength of the finished product for Welded Sheet Metal parts. However, we will ship the product after confirming that the component parts are welded and joined.