- HELP

- Technical Information

- Sheet metal

- Applicable parts/Materials

- Material Properties

Material Properties

Ferrous Metals

Material – Features / Appearance

| Material | Features | Appearance |

|---|---|---|

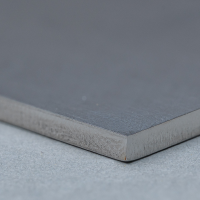

| A cold-rolled steel sheet for general press-formed sheet metal. It is characterized by high dimensional accuracy and good appearance, but it is prone to rust. Surface treatment is recommended after processing. The general standard thickness range is 0.2mm~3.2mm. |  |

| Low Carbon Steel (Hot Rolled) | A hot-rolled mild steel sheet for general use and drawing. As with SPCC, surface treatment is recommended after processing to prevent rust. It is typically used for medium thickness products. The general standard thickness range is 1.2mm or more. |  |

| Low Carbon Steel (Hot Rolled) | A rolled steel material widely used for general structural applications. The name is derived from its tensile strength of 400 N/mm^2 or higher. It is characterized by low cost and good workability and is used in a wide range of industries including machinery and construction. |  |

Material Properties *The following values are for reference only and are not guaranteed.

| Material | Tensile strength (N/mm2) | Yield (N/mm2) | Elongation at Break % | Flexural strength (N/mm2) | Compressive strength (N/mm2) | Yield point (N/mm2) | Young’s Modulus (N/mm2) | Flexural modulusa (N/mm2) | Specific Gravity | Electrical Conductivity (S/m) | Thermal Conductivity (W/m・K) | Coefficient of Linear Expansion (/℃) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Low Carbon Steel (Cold Rolled) | 270~410 | 205 or more | 32 or more | 243~390 | 260~400 | 205 or more | 2.1×10⁵ | 2.1×10⁵ | 7.85 | 6.96×10⁶ | 58 | 11.7×10⁻⁶ |

| Low Carbon Steel (Hot Rolled) | 270~440 | 175 or more | 35 or more | 243~418 | 260~430 | 175 or more | 2.1×10⁵ | 2.1×10⁵ | 7.85 | 6.96×10⁶ | 58 | 11.7×10⁻⁶ |

| Low Carbon Steel (Hot Rolled) | 400~510 | 215 or more | 21 or more | 360~485 | 380~485 | 215 or more | 2.1×10⁵ | 2.1×10⁵ | 7.85 | 6.96×10⁶ | 58 | 11.7×10⁻⁶ |

Stainless Steel

Material – Features / Appearance

| Material | Features | Appearance |

|---|

| 304 Stainless Steel (2B) | An austenitic stainless steel with improved corrosion resistance and weldability. It is a versatile widely available material used in various industries. Because of its excellent weldability, high corrosion resistance and strength, it is often used for facilities, equipment, and machinery. |  |

| 304 Stainless Steel (Single-Sided #400-Grit Polished) | A finished stainless steel sheet used for exterior covers, offering excellent appearance. The surface has a near-mirror gloss with slight polishing marks. It is typically supplied with a protective film to preserve its appearance. |  |

| 304 Stainless Steel (Single-sided hairline finish) | A finished stainless steel sheet with long, continuous grain lines from polishing. The surface has a low gloss, giving it a calm and refined appearance. It is typically supplied with a protective film to preserve its appearance. |  |

| 304 Stainless Steel (No.1) | A standard finish material that is hot-rolled, heat-treated, and pickled to remove scale and surface impurities. It has a matte textured surface. |  |

| 304 Stainless Steel (for Shims) | A cold worked and hardened material with high tensile strength. It has minimal warping after processing and is not suitable for bending or drawing. It has better thickness tolerance than 2B material making it ideal for precision machining. |  |

| 304 Stainless Steel (No.4) | A material with good corrosion resistance and an attractive and practical surface finish commonly used for exterior covers. The surface has a brushed finish reducing reflectivity. |  |

| 316 Stainless Steel (2B) | An austenitic stainless steel with improved corrosion and pitting resistance compared to 304SS. It is suitable for harsh environments exposed to salt water and chemicals. Often used when corrosion may lead to critical failures. |  |

| 430 Stainless Steel (2B) | A magnetic ferritic stainless alloy. Unlike austenitic stainless steels, it does not contain nickel and has low corrosion resistance. Due to its versatility and availability it is widely used in everyday applications, including the food industry. |  |

Material Properties *The following values are for reference only and are not guaranteed.

| Material | Tensile strength (N/mm2) | Yield (N/mm2) | Elongation at Break % | Flexural strength (N/mm2) | Compressive strength (N/mm2) | Yield point (N/mm2) | Young’s Modulus (N/mm2) | Flexural modulusa (N/mm2) | Specific Gravity | Electrical Conductivity (S/m) | Thermal Conductivity (W/m・K) | Coefficient of Linear Expansion (/℃) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 304 Stainless Steel | 520~690 | 205 or more | 40 or more | 478~670 | 495~520 | 205 or more | 1.9×10⁵ | 1.9×10⁵ | 7.93 | 1.39×10⁶ | 16.2 | 17.3×10⁻⁶ |

| 304 Stainless Steel (for Shims) | 650~900 | 450 or more | 10 or more | 598~873 | 620~860 | 450 or more | 1.9×10⁵ | 1.9×10⁵ | 7.93 | 1.39×10⁶ | 16.2 | 17.3×10⁻⁶ |

| 316 Stainless Steel | 520~690 | 205 or more | 40 or more | 478~670 | 495~520 | 205 or more | 1.9×10⁵ | 1.9×10⁵ | 7.98 | 1.39×10⁶ | 15 | 16.0×10⁻⁶ |

| 430 Stainless Steel | 450~470 | 205 or more | 22 or more | 405~428 | 450~470 | 205 or more | 2.0×10⁵ | 2.0×10⁵ | 7.70 | 1.39×10⁶ | 25 | 10.4×10⁻⁶ |

Aluminum

Material – Features / Appearance

| Material | Features | Appearance |

|---|---|---|

| 5052 Aluminum Alloy | One of the most common aluminum alloys with excellent machinability and corrosion resistance. Due to its versatility and ease of use it is widely used across many industries. |  |

| 6061 Aluminum Alloy | An aluminum alloy with enhanced corrosion resistance and heat treatment properties. Its corrosion resistance is one of the highest among aluminum alloys. The T6 temper (artificial aging heat treatment) provides high tensile and yield strength. It is often used in outdoor and harsh saltwater or chemical environments. |  |

Material Properties *The following values are for reference only and are not guaranteed.

| Material | Tensile strength (N/mm2) | Yield (N/mm2) | Elongation at Break % | Flexural strength (N/mm2) | Compressive strength (N/mm2) | Yield point (N/mm2) | Young’s Modulus (N/mm2) | Flexural modulusa (N/mm2) | Specific Gravity | Electrical Conductivity (S/m) | Thermal Conductivity (W/m・K) | Coefficient of Linear Expansion (/℃) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5052 Aluminum Alloy | 195~260 | 110 or more | 12 or more | 180~252 | 185~260 | 110 or more | 7×10⁴ | 7×10⁴ | 2.68 | 1.91×10⁷ | 138 | 23.8×10⁻⁶ |

| 6061 Aluminum Alloy | 260~310 | 240~270 | 8–15 | 280 | 280 | 240~270 | 6.9×10⁴ | 6.9×10⁴ | 2.7 | 2.5×10⁷ | 167 | 23.6×10⁻⁶ |

Pre-finished Sheets

Material – Features / Appearance

| Material | Features | Appearance |

|---|---|---|

| Cold Rolled Low Carbon Steel (Electrolytic Zinc Plating) | A galvanized steel, plated SECC sheet. It offers shorter lead times than post-treated products, but machined surfaces will lack plating. Minor surface scuffing may occur due to material characteristics. |  |

| Cold Rolled Low Carbon Steel (Galvanized) | A galvanized steel sheet often used in construction materials. Compared to SECC (electro-galvanized steel sheet) it has a thicker plating resulting in higher corrosion resistance. |  |

| 5052 AL Alloy Pre-Finish, Clear Anodize | A corrosion and wear resistant material with a lower cost and shorter lead time than post-treated products. When used for bending, cracks may appear and plating may peel off around the bends due to the characteristics of the material. |  |

| 5052 AL Alloy Pre-Finish, Black Anodize |  |

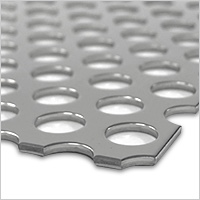

Perforated Metal

Material – Features / Appearance

| Material | Features | Appearance |

|---|---|---|

| Perforated Metal – 60° Staggered Round Hole Type – (304 Stainless Steel-BA, Bright Annealed) | A perforated steel sheet widely used for ventilation covers and filters. It has a lower cost than machining hole patterns into standard steel sheets. Warp correction is performed before shipment but slight distortion may remain due to material characteristics. Available hole patterns include:

|

|

Transparent resin plate

Material – Features / Appearance

| Material | Features | Appearance |

|---|---|---|

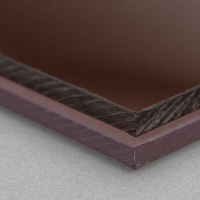

| PET (Polyethylene Terephthalate) | Available in two colors with different light transmittance and in standard or anti-static grades. It has excellent chemical resistance, water resistance, and electrical insulation properties at a low cost. It has high transparency and good processability and is often used in food containers, optical films and insulating materials. . |  |

| Acrylic | Available in two colors with different light transmittance and in standard or anti-static grades. It has very high transparency and light transmission and is often used in displays, lighting covers, and interior applications. However, it is vulnerable to petroleum-based solvents and alkaline chemicals. |  |

| Polycarbonate | Available in two colors with different light transmittance and in standard or anti-static grades. It has excellent impact resistance, heat resistance, and dimensional stability as well as high light transmission. Often used for covers, window materials, and protective panels. It also has good machinability and can be used for machine parts. |  |

| PVC (polyvinyl chloride) | Available in two colors with different light transmittance and in standard or anti-static grades. It has excellent chemical resistance, water resistance, and electrical insulation. It is rigid and has high dimensional stability and good processability. Often used in piping parts, housings, and insulating materials. |  |

Material Properties *The following values are for reference only and are not guaranteed.

| Material | Tensile strength (N/mm2) | Flexural strength (N/mm2) | Elongation at Break % | Young’s Modulus (N/mm2) | Rockwell hardness | Specific Gravity | Continuous use temperature ℃ |

|---|---|---|---|---|---|---|---|

| PET (Polyethylene Terephthalate) | 55~65 | 80~100 | 50~100 | 2900 | M80~M90 | 1.38 | 80~100 |

| Acrylic | 65~75 | 90~120 | 2~7 | 3000 | M85~M100 | 1.19 | 70~90 |

| Polycarbonate | 60~70 | 80~95 | 90~120 | 2400 | M70~M80 | 1.2 | 100~120 |

| PVC (polyvinyl chloride) | 45~55 | 70~90 | 20~40 | 2800 | R110~R120 | 1.4 | 50~70 |

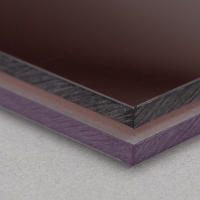

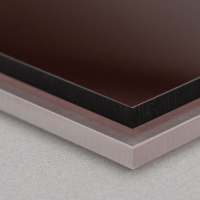

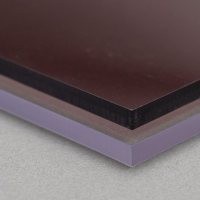

Aluminum composite sheet

Material – Features / Appearance

| Material | Features | Appearance |

|---|---|---|

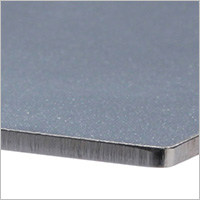

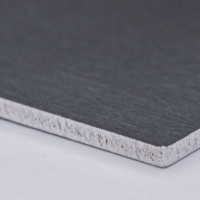

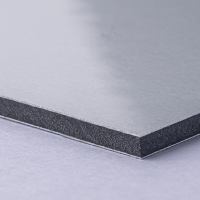

| Aluminum composite sheet – Silver | It has a sandwich structure of aluminum + foam polyethylene resin + aluminum. It is lighter than metal and more rigid than resin due to thin aluminum surface layers. Surface metal layers may become sharp due to material characteristics. |  |

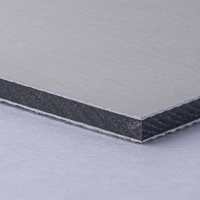

| Aluminum composite sheet – Frosted Silver |  |

|

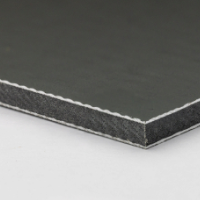

| Aluminum composite sheet – Black |  |