- HELP

- How to use

- Quotation conditions settings

- [CNC Milling] Quotation Settings

- Hardness Selection (Full Part Hardening)

Hardness Selection (Full Part Hardening)

How to set up Full Part Hardening

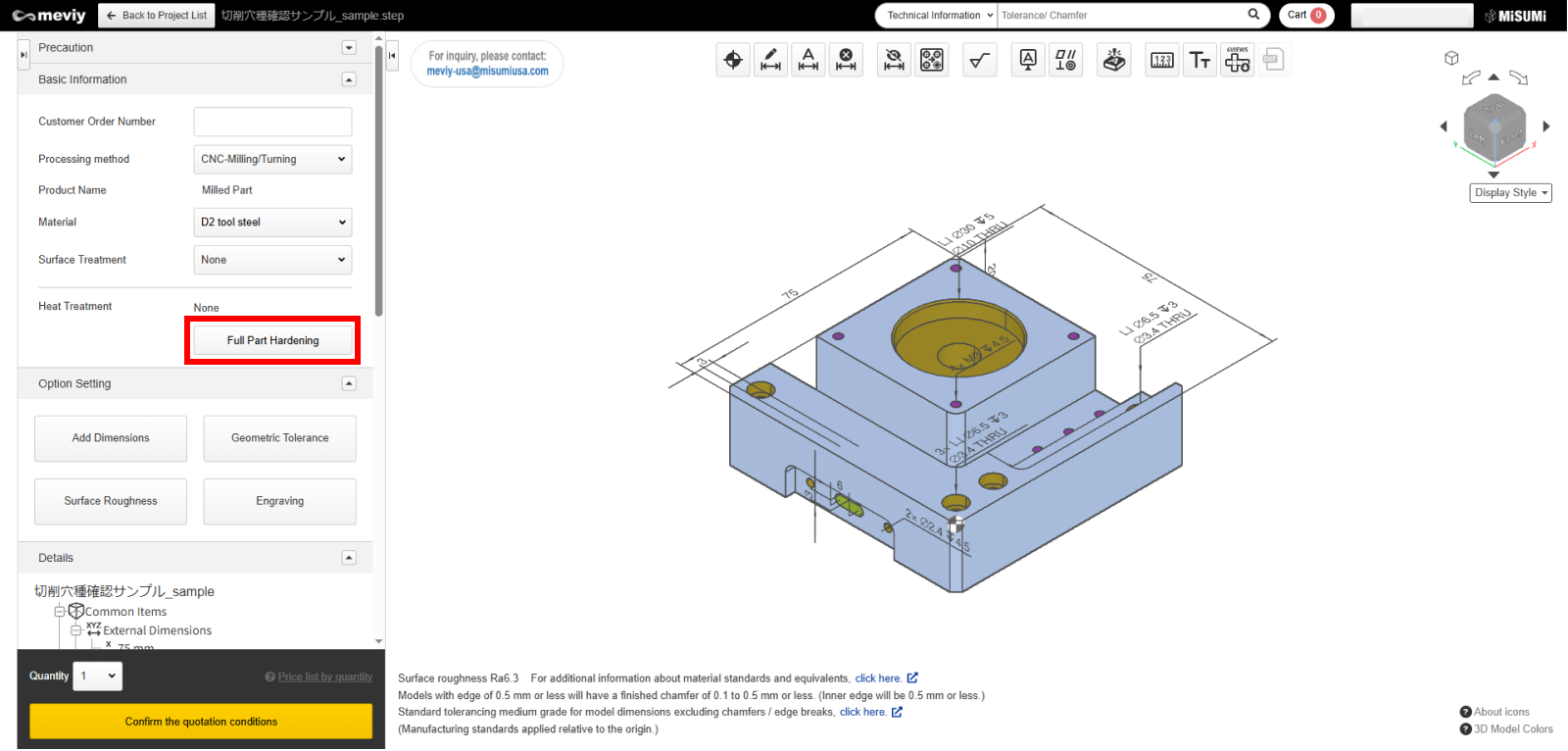

STEP1

Click “Full Part Hardening” button in the Basic Information section.

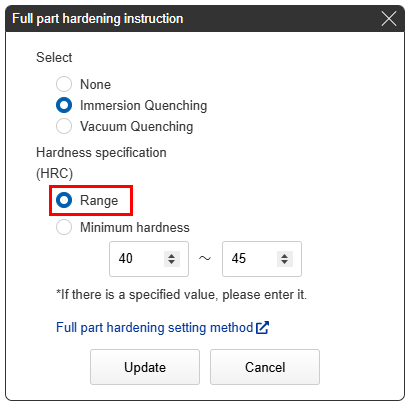

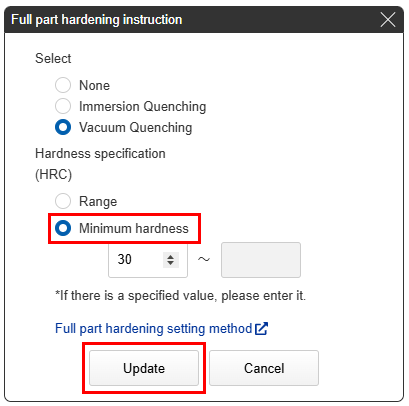

STEP2

When a hardening type is specified in the Full part Hardening dialog box, the standard hardness range is displayed in the “Hardness specification (HRC)” fields.

If you want to specify a hardness other than the standard hardness, enter a lower limit and upper limit in the “Hardness (HRC)” input box.

Finally, click the “Update” button.

Possible hardness settings by material

| Material | Standard hardness | Hardness range that can be automatically estimated (HRC) |

|---|---|---|

| D2 tool Steel | HRC58~63 | HRC50~63 |

| 4140 Alloy Steel | HRC50~55 | HRC30~55 |

| 1049 Carbon Steel | HRC35~45 | HRC30~50 |

| 1045 Carbon Steel | HRC30~40 | HRC30~45 |

| DC53 Tool Steel | HRC58~63 | HRC50~63 |

| SK105 Tool Steel | HRC58~63 | HRC58~63 |

| O1 Tool Steel | HRC58~63 | HRC58~63 |

- When specifying a hardness range, there must be 5 (HRC) or more between minimum and maximum values. Example: HRC40~45

- When specifying a minimum hardness, only the lowest value for the desired hardness (HRC) must be entered.

- When specifying a minimum hardness, the value entered can be up to 5 HRC less than the maximum allowable hardness value. Example: For D2 tool steel, HRC58~

- *Hardness (HRC) is guaranteed to be above the minimum specified hardness value.

Tip

The minimum hardness specification is selected by entering only the minimum value for the desired hardness (HRC).

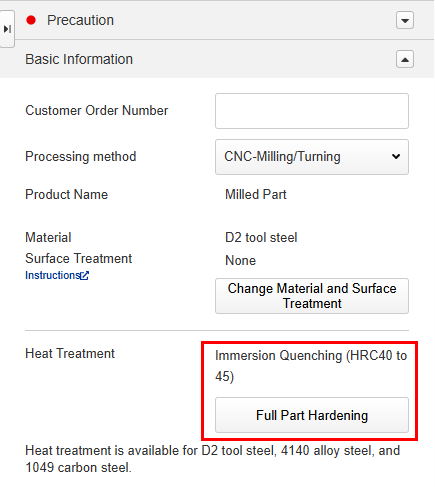

STEP3

The change to the hardening selection can be confirmed in the “Basic Information” section next to “Heat Treatment” .

Tip

If the material is changed after selecting Full Part Hardening, the hardness will automatically change to the standard hardness of the material after the change.Reference>>>How to set up Full Part Hardening STEP2