- HELP

- How to use

- Quotation conditions settings

- [CNC Turning ] Quotation Settings

- Hardness Selection (Full Part Hardening or Selective Hardening)

Hardness Selection (Full Part Hardening or Selective Hardening)

How to set up Full Part Hardening

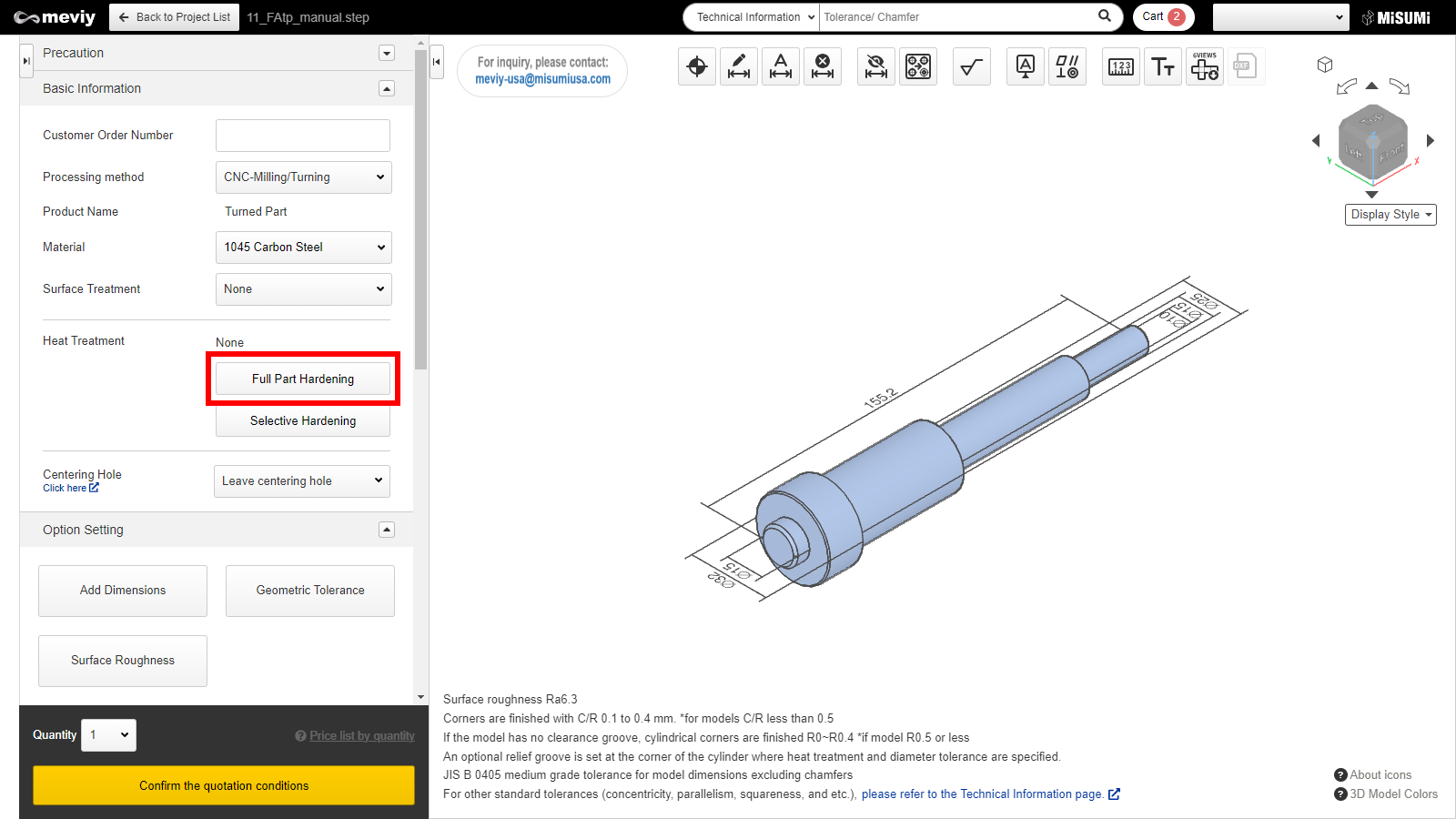

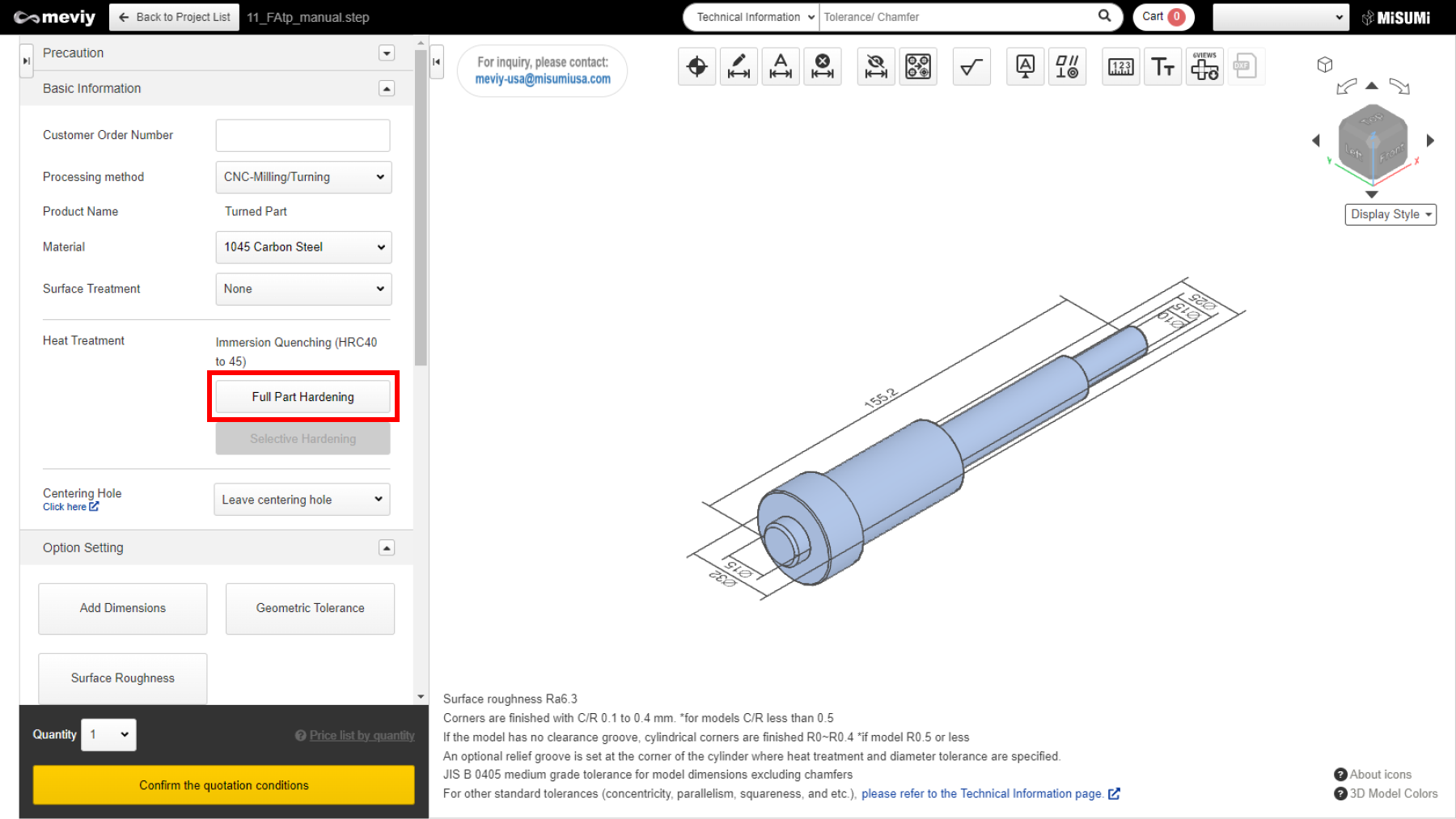

STEP1

Click “Full Part Hardening” button in the Basic Information section.

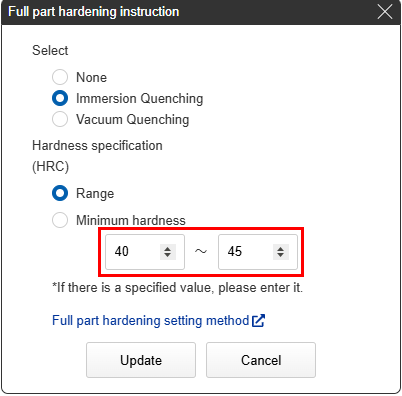

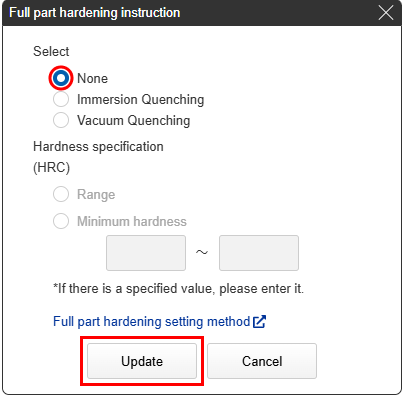

STEP2

- When a hardening type is specified in the Full part Hardening dialog box, the standard hardness range is displayed in the “Hardness specification (HRC)” fields.

- If you want to specify a hardness other than the standard hardness, enter a lower limit and upper limit in the “Hardness (HRC)” input box.

- Finally, click the “Update” button.

Hardness by material

*Hardness (HRC) is guaranteed to be above the minimum specified hardness value.

| Standard hardness (HRC) | Hardness range that can be automatically estimated (HRC) | |

|---|---|---|

| 1045 carbon steel | HRC40~45 | HRC30~45 |

| 4135 alloy steel | HRC35~40 | HRC30~45 |

| 4140 alloy steel | HRC50~55 | HRC30~55 |

| O1 tool steel | HRC58~63 | HRC40~63 |

| D2 tool Steel | HRC58~63 | HRC50~63 |

| H13 tool Steel | HRC50~55 | HRC40~55 |

| 52100 alloy Steel | HRC58~63 | HRC35~63 |

| 440C SS | HRC55~60 | HRC45~63 |

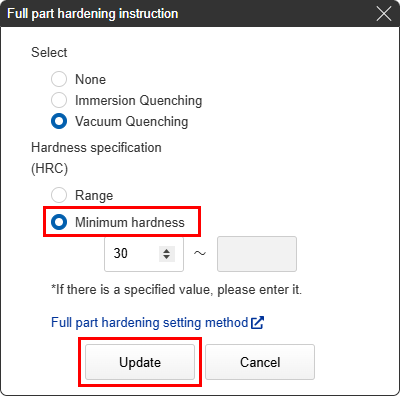

Tip

The minimum hardness specification is selected by entering only the minimum value for the desired hardness (HRC).

Tip

- Immersion Quenching and Vacuum Quenching are different hardening methods. The finished appearance will differ.

- Reference>>>Quenching Quality Standards

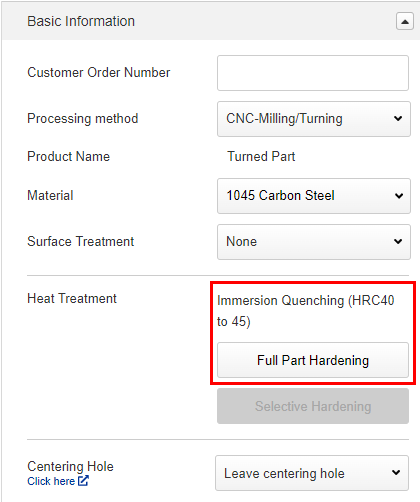

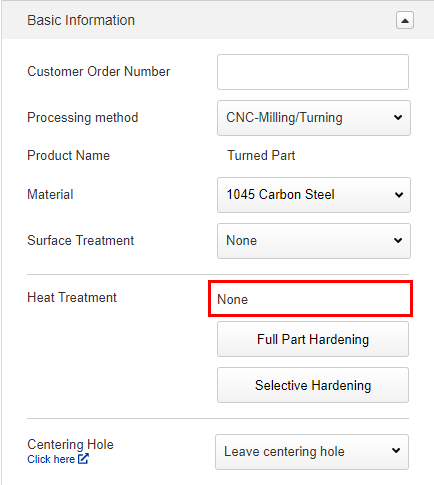

STEP3

The change to the hardening selection can be confirmed in the “Basic Information” section next to “Heat Treatment” .

Tip

- If the material is changed after selecting Full Part Hardening, the hardness will automatically change to the standard hardness of the material after the change.

- Reference>>>How to set up Thorough Hardening STEP2

How to delete Full Part Hardening

STEP1

Click “Full Part Hardening” button in the Basic Information section.

STEP2

Select “None” and click Update.

STEP3

Confirm that the hardness selection has been deleted.

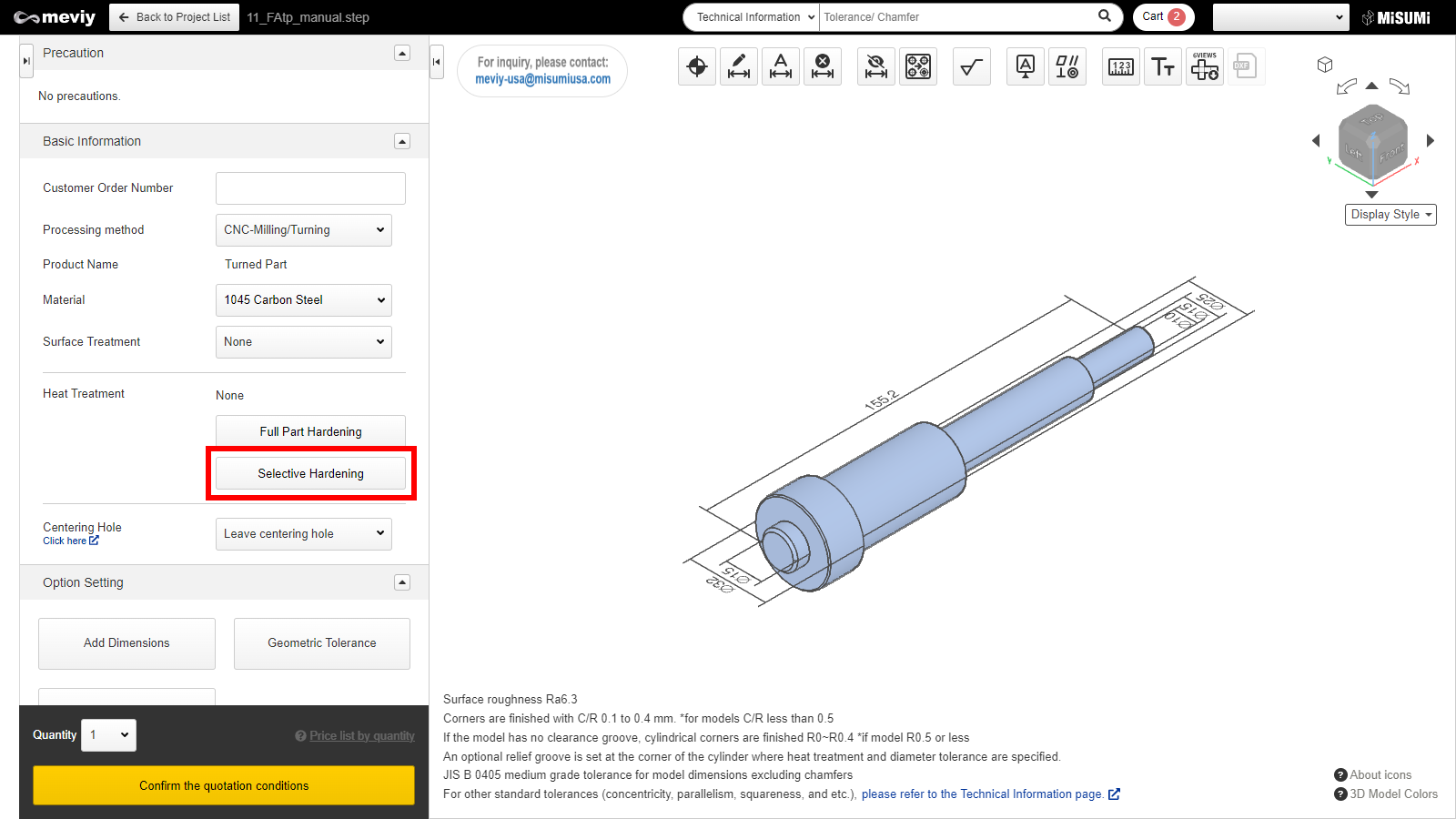

How to set up Selective Hardening

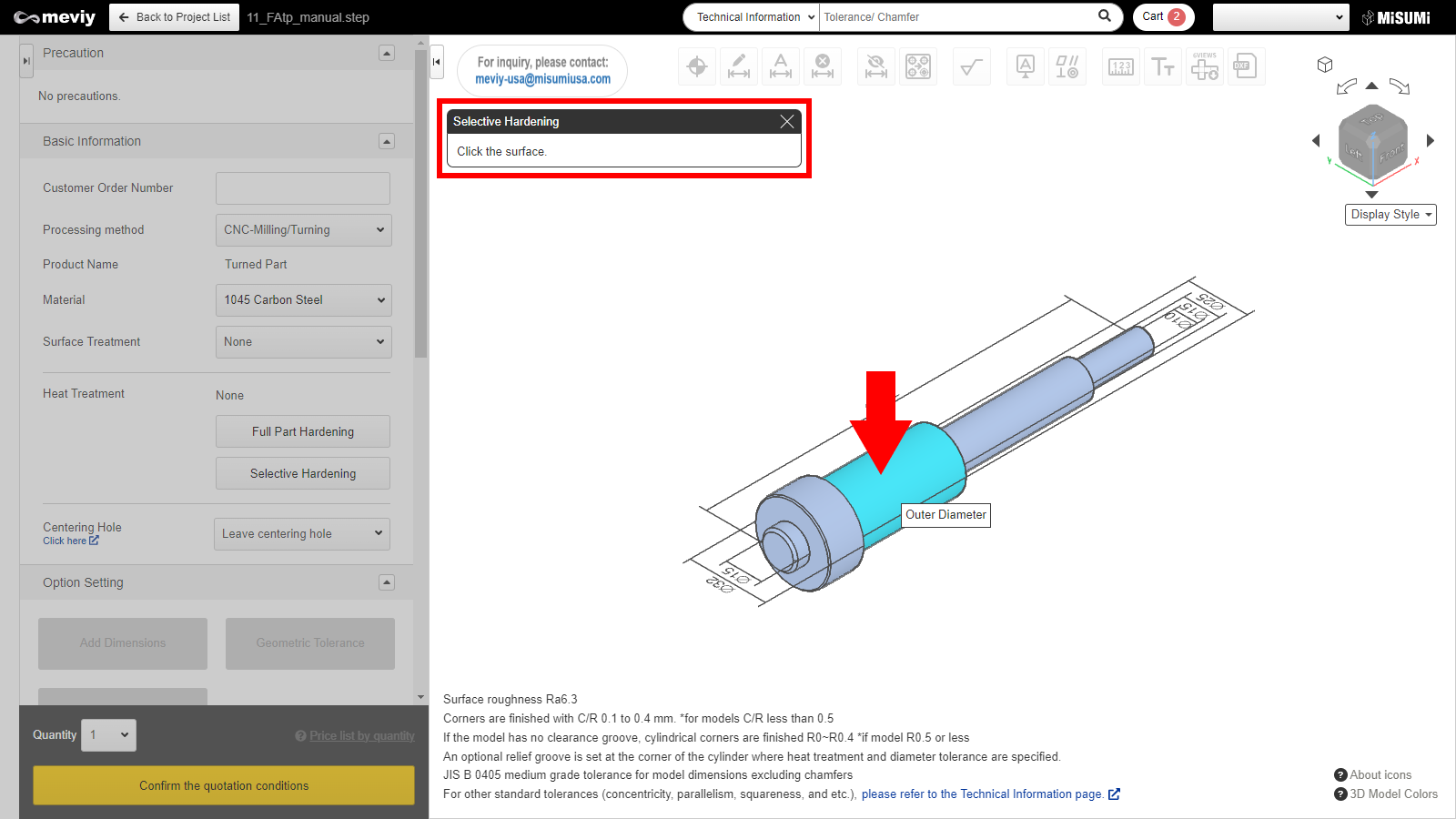

STEP1

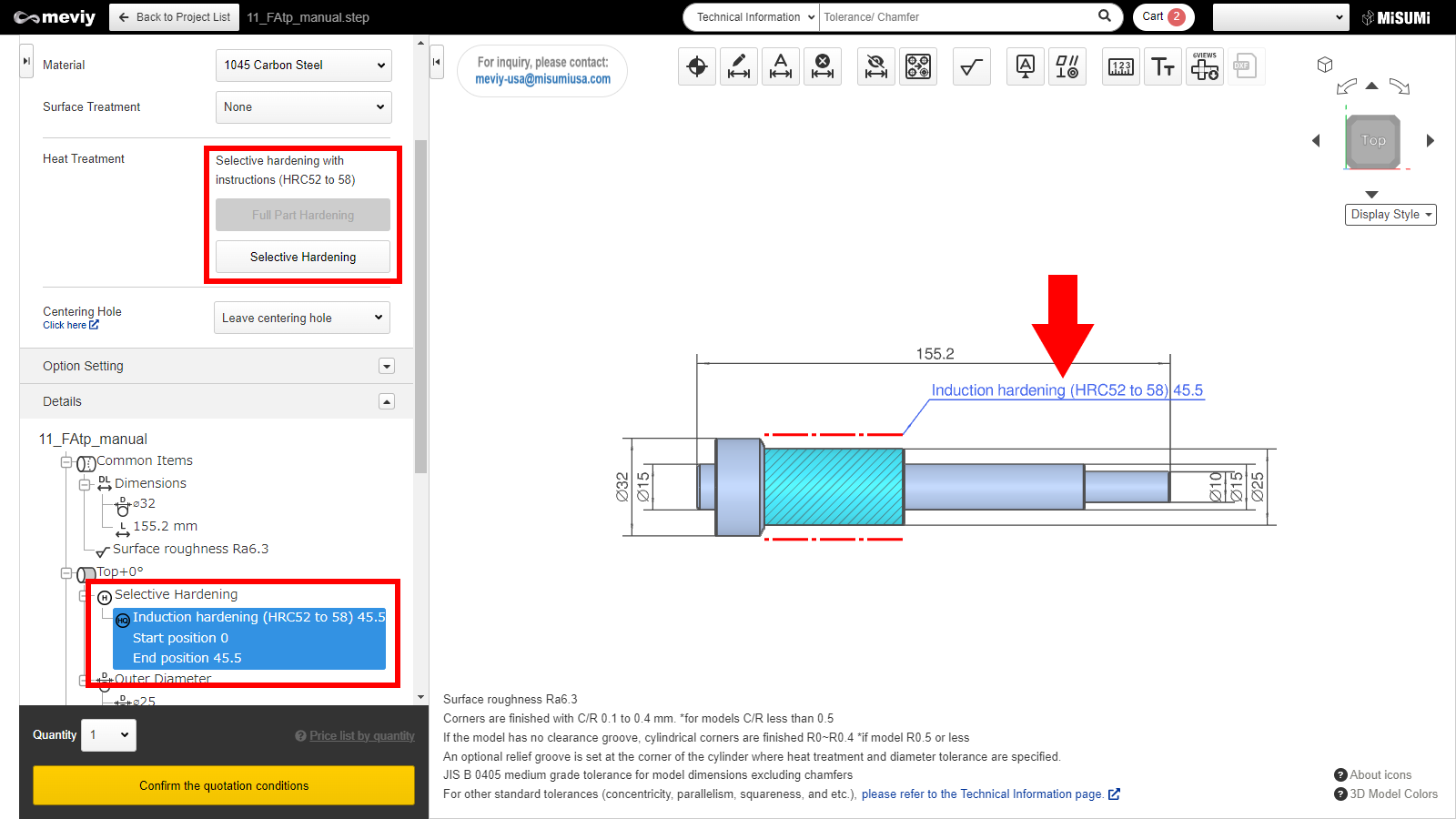

Click “Selective Hardening” button in the Basic Information section.

STEP2

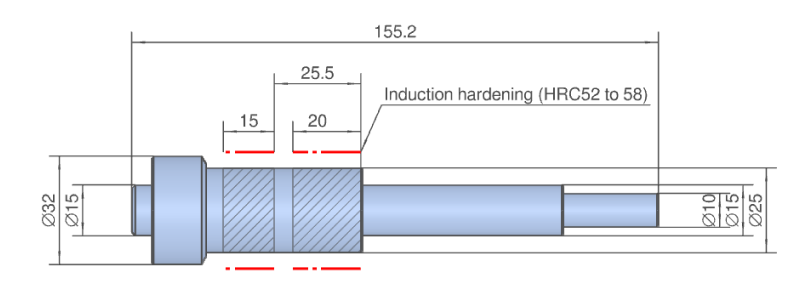

- Select the surface to be used as the datum reference. The selected surface will be highlighted.

- Only outer diameter surfaces can be selected.

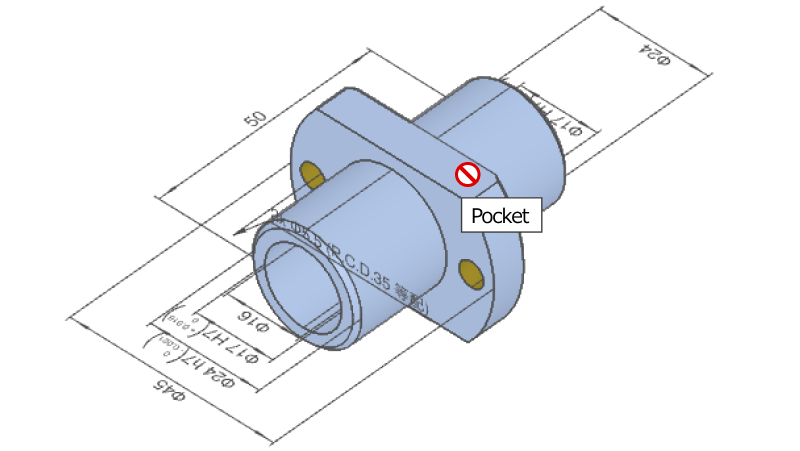

Caution

If the surface is not selectable, the “Not Selectable” icon will be displayed when the mouse hovers over it.

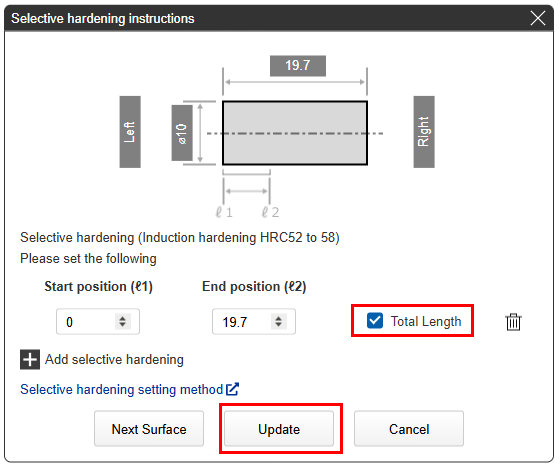

STEP3

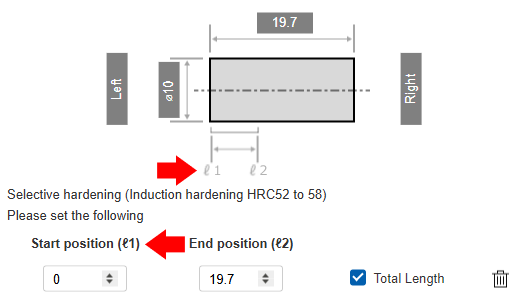

By default, “Total Length” is selected. This specifies the total length of the selected surface for hardening. Click “Update”.

Notes

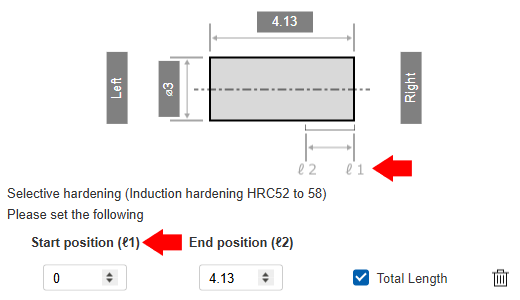

You can also specify the start and end position for hardening. |

|

| Right side start position | Left side start position |

|---|

Notes

|

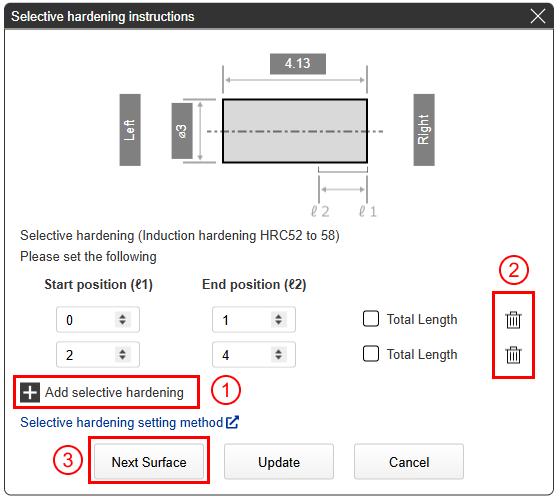

①Multiple ranges can be specified at multiple locations within the same surface.

|

STEP4

After updating, the Selective Hardening settings will appear in the model view and tree view.

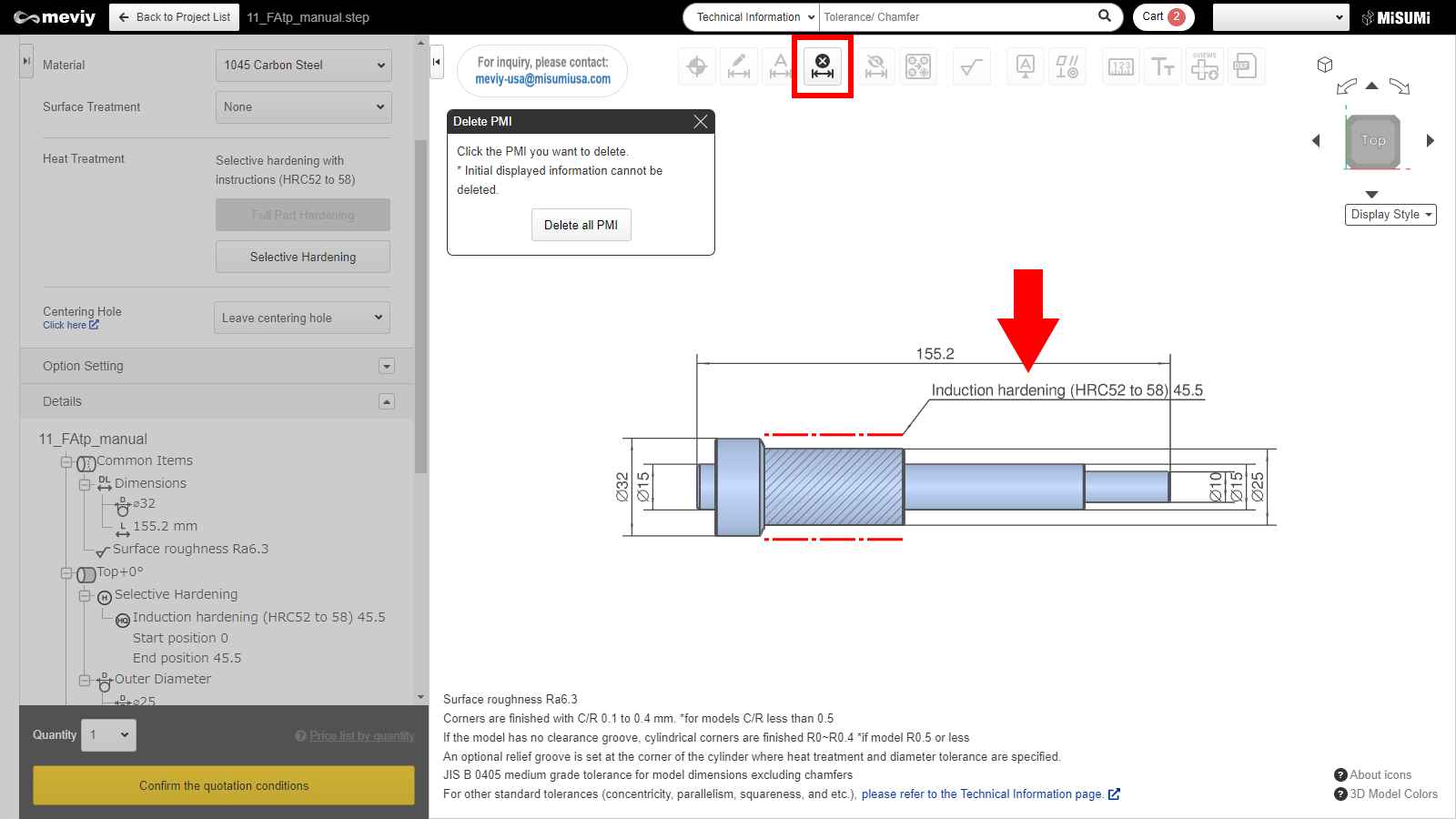

How to delete Selective Hardening

STEP1

- Select

from the icons at the top of the screen.

from the icons at the top of the screen. - The shortcut key (D) can also be used.

Tip

- Selective Hardening can also be deleted by double-clicking the note on the model view.

- Reference>>> Selective Hardening STEP3

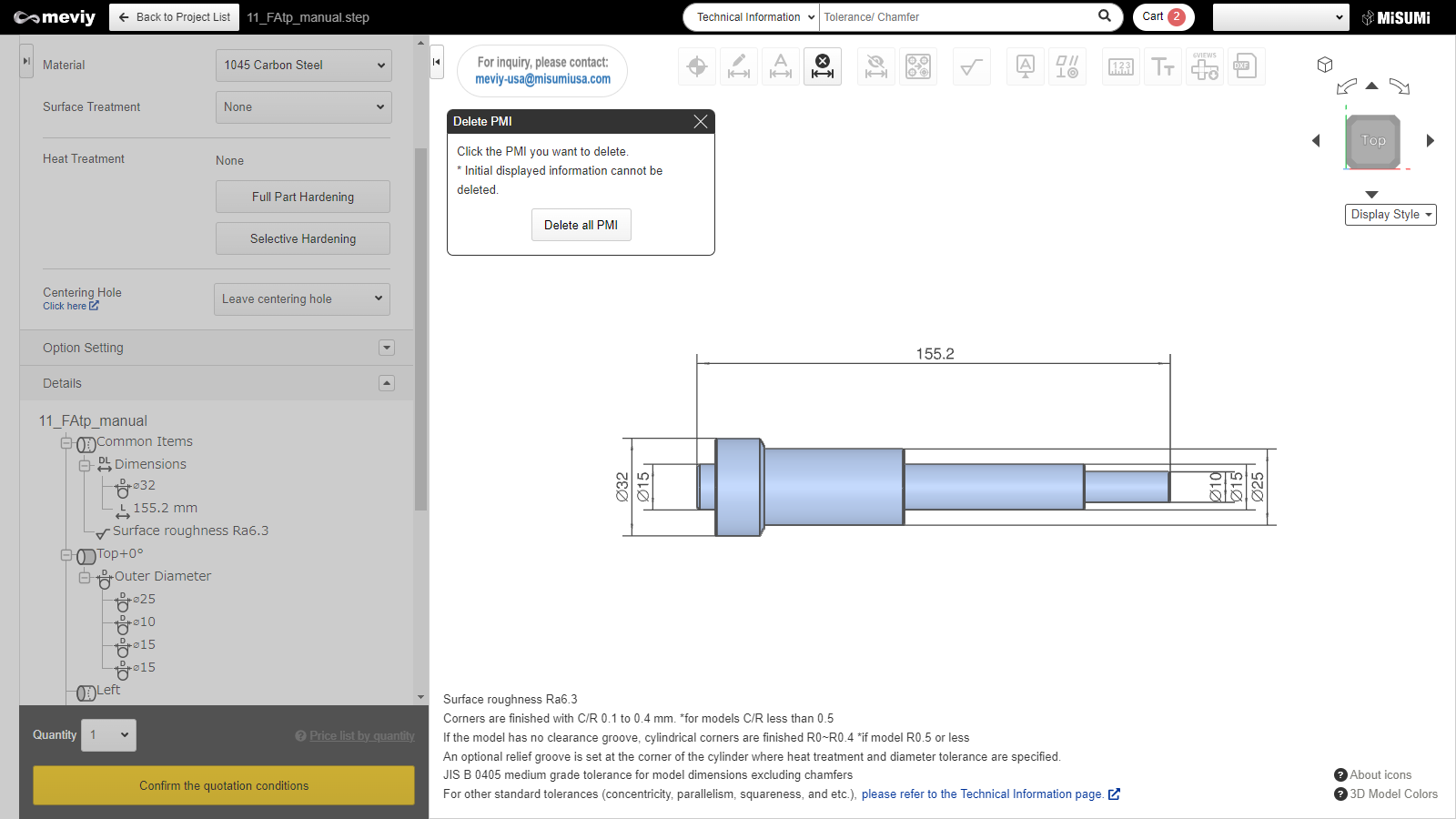

STEP2

- Confirm that the hardness selection has been deleted.

- Press the Esc key or click the x button when finished.