Quality Control

External Appearance Quality Control Range

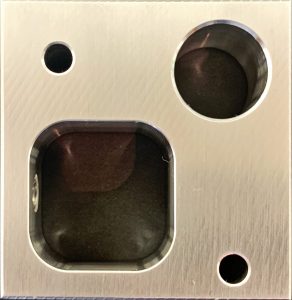

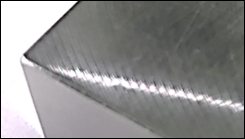

| Milling Face | ||

|---|---|---|

|  |  |

|

|

|

| Untreated surface | ||

|  |  |

|

|

|

- No hooks and a dot gauge guarantee of scratches of 0.7 mm or smaller.

-

Surface roughness: √Ra6.3 or 3.2 [√Rz25 or 12.5]The surface roughness conforms to the value specified by the user.

- Depending on the material and size, the product may be shipped with an untreated surface (polishing and rolling).

Surface Treatment

| Suspension method image | Surface treatment suspension and electrode contact marks | |

|

|

|

| Anodized aluminum (black) | Anodized aluminum (clear) | |

- Since film thickness management is difficult for small diameter precision holes, etc., additional machining may be carried out after processing, and as a result, the surface treatment may not remain on the cutting surface.

- Hanging marks and electrode contact marks from surface treatment may remain on the product.

- For products with surface treatment, the exact color spec is not guaranteed.

- The exact color spec cannot be specified using Munsell or RAL values.

- Color may very, even among products with the same material and surface treatment.

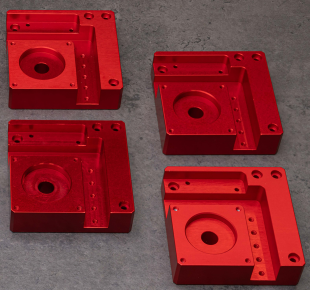

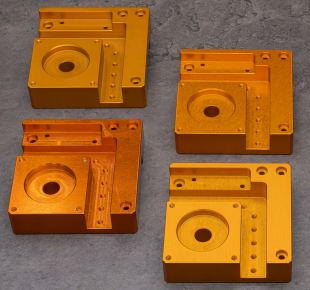

Example of Red anodizing

Example of Gold anodizing

Please refer to the pictures on the left for the color of Red and Gold anodized products.

Inspection Item

Inspections are Carried Out at Each Work Stage and Before Shipment

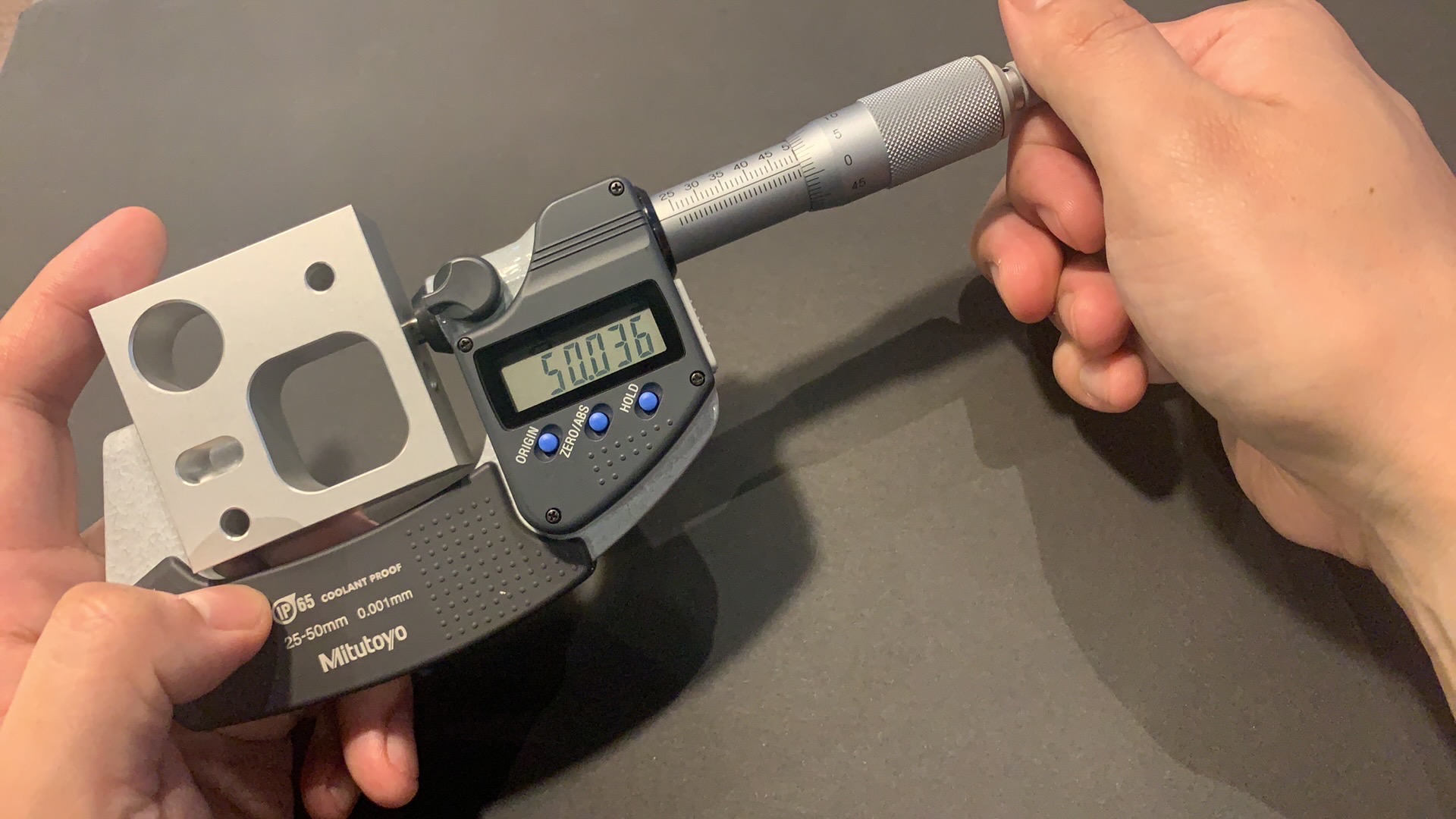

Dimensional tolerance inspection

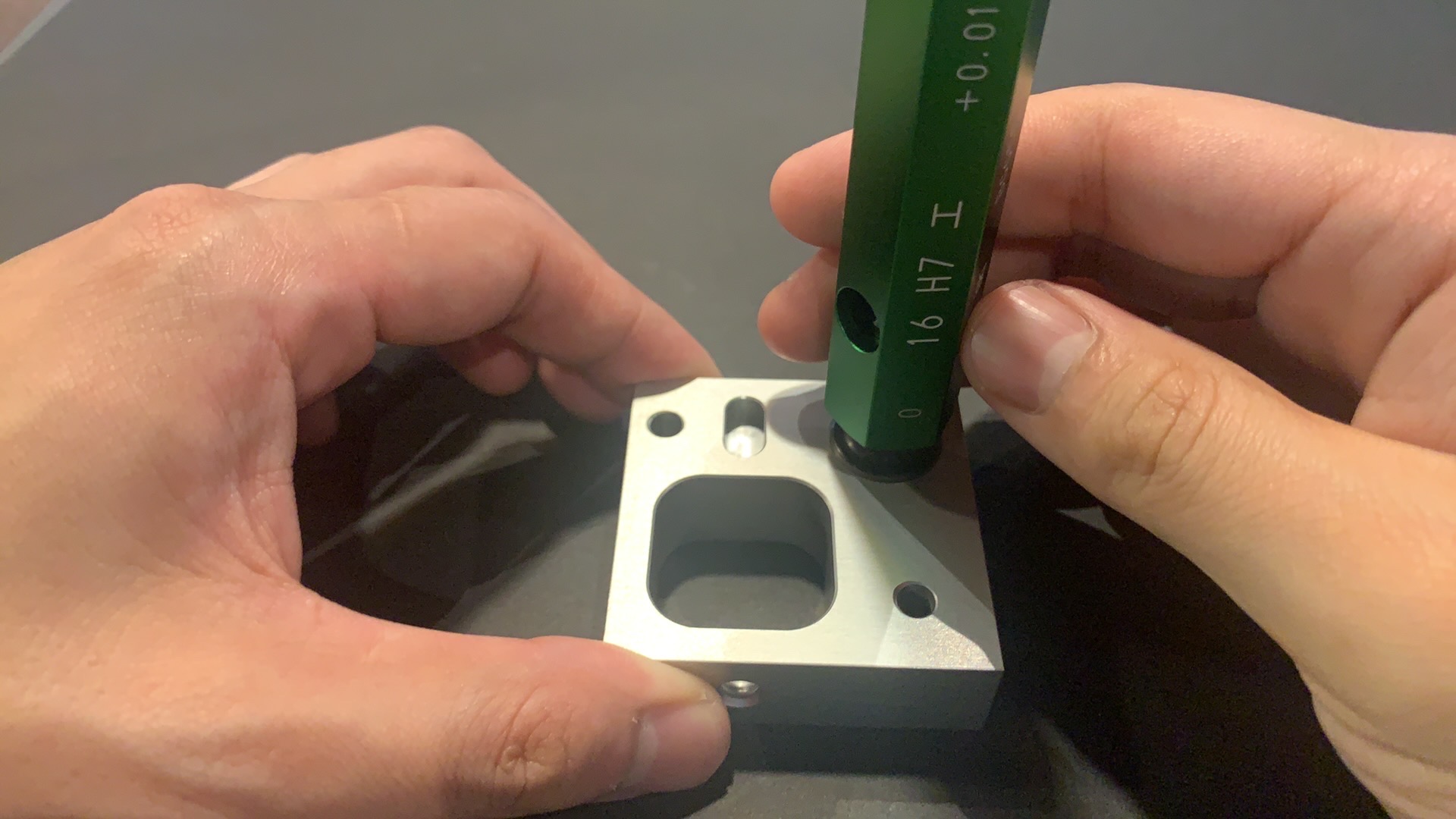

Fit tolerance inspection

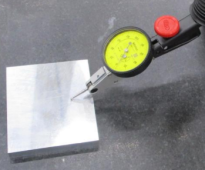

Geometric tolerance inspection

Screw inspection, etc.

ISO2-grade (JIS B 2025) equivalent Bolts pass through in principle.

Visual inspection

Inspection with roughness standard specimen, dot gauge,and roughness tester.

Surface Roughness Inspection

Angular Tolerance Inspection

Bevel Protractor

Dimensional Assurance Range

| Corner chamfering | |

|

|

For sharp corners (C0.5 mm and smaller), the external corner chamfer tolerance is C0.1 mm to 0.5 mm, and the internal corner radius tolerance is R0.5 mm or less.

| Chamfering unspecified hole entrances | |

|

|

Entrance chamfer is 0.1 to 0.5 mm or less.

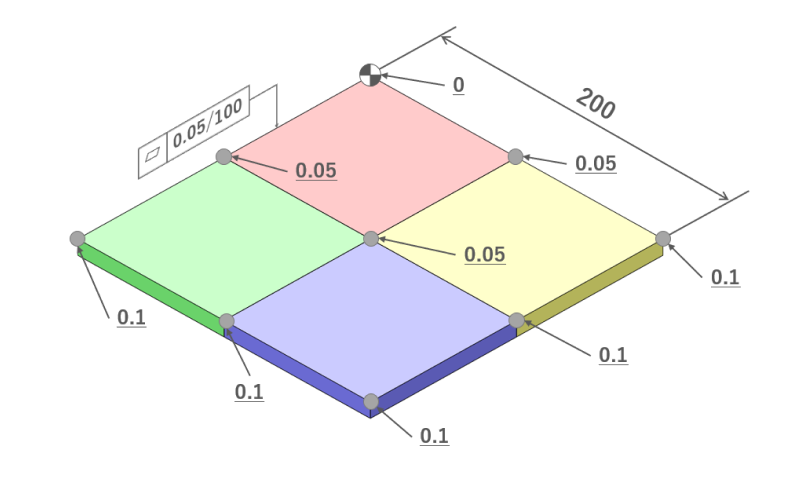

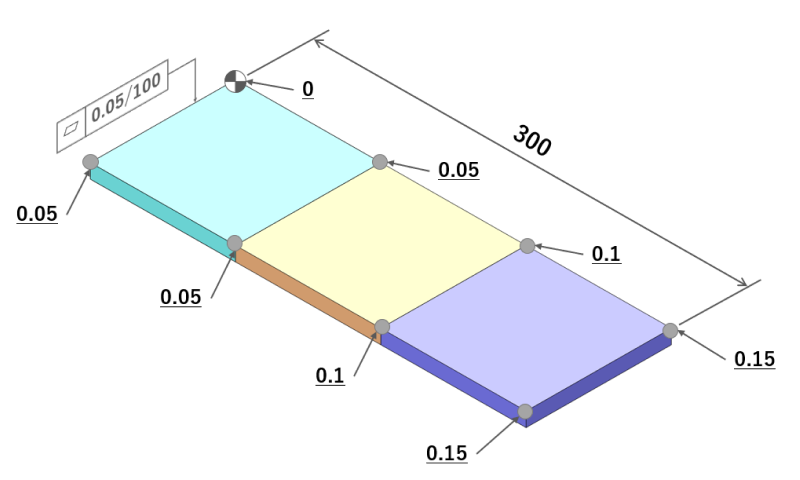

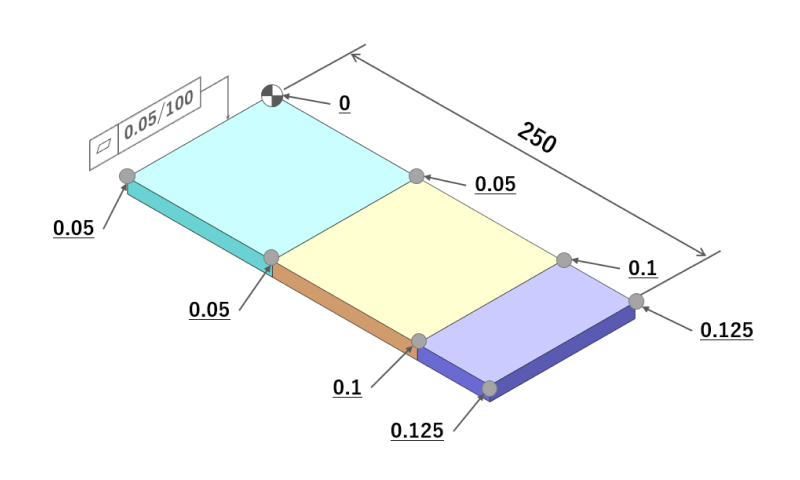

Ensure the specified geometric tolerances

- Specified values are guaranteed per 100 mm.

- i.e., If a flatness of 0.05/100mm is specified

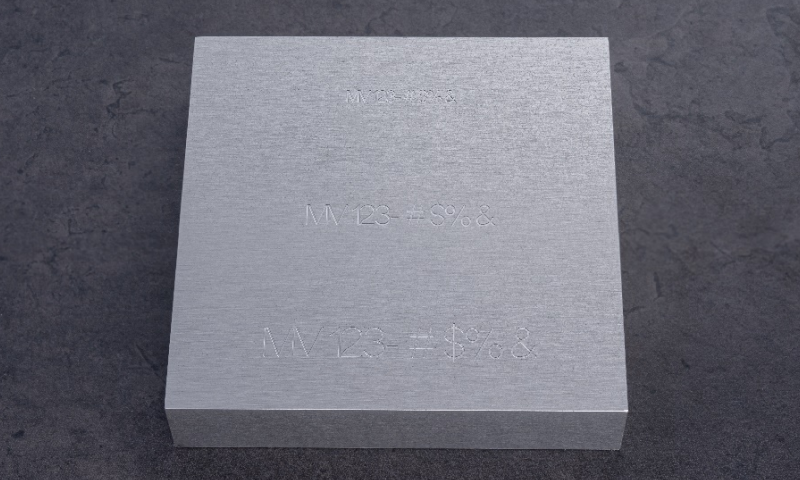

Engraving quality assurance coverage

Processing method

Engraving will be done by either Laser Engraving or Machining.

*The processing method cannot be specified

Quality precautions for engraving

- 1. There may be burrs or burns on the engraved area.

- 2. If the font size is 3~5mm, depending on the characters, there may be insufficient space between the characters or the characters may be distorted.

- 3. Depending on the material and surface treatment, the engraved characters may become thinner.

- 4. The “font size and angle” on the engraving are approximate values. Dimensional accuracy is not guaranteed.

- 5. Depending on the text content, the size may differ from the specified size.

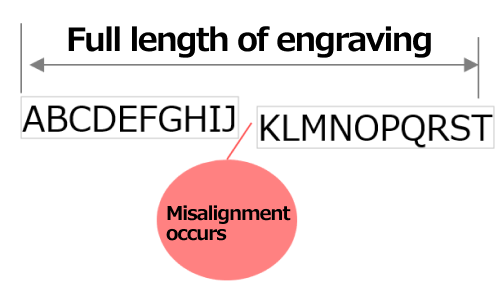

- 6. Depending on the total length of the engraving, discrepancies in character spacing and height may occur (guideline: length 90mm or more)

Example of engraved surface

- Laser engraving

- (Material:304 Stainless Steel)

- Machining engraving

- (Material:304 Stainless Steel)

- Laser engraving

- (Material:5052 Aluminum Alloy)

- *With Black anodize

- Machining engraving

- (Material:5052 Aluminum Alloy)

- *With Clear anodize

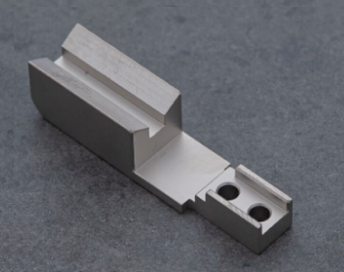

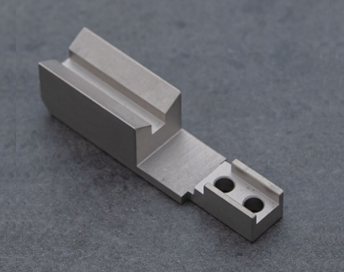

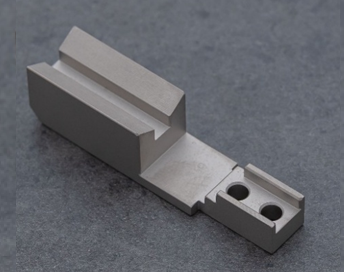

Quenching Quality Standards

About hardening quality assurance

The hardness value specified is guaranteed and will be measured and confirmed before shipping.

Material:D2 tool steel

, Surface

Treatment:Electroless nickel plating

Material:1049 Carbon Steel, Surface Treatment:Electroless nickel plating

Finish without grinding

Material:1049 Carbon Steel, Surface Treatment:Electroless nickel plating

Finish with grinding

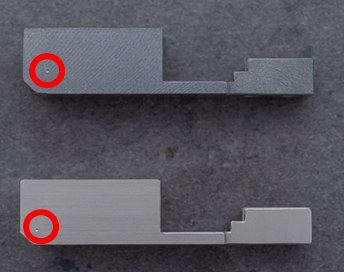

Inspection marks

Caution

- The hardened depth and distribution of heat treated areas may vary depending on the thickness and shape of the material.

- When parts are heat treated, the outer surface tends to be harder, while the inner areas tend to remain softer. During inspection the hardening will be confirmed to be uniform on average.

- Media blasting may be performed to remove surface contamination after quenching. There will be no change in accuracy after the treatment. Blast type cannot be specified.

- Grinding may be performed during the finishing process.

- Grinding cannot be specified. The factory will determine if grinding is necessary to guarantee dimensional accuracy.

- Hardness measurement marks may remain in areas. To confirm the inspection points in advance, please add information in the comments and request a manual quote.

Packaging

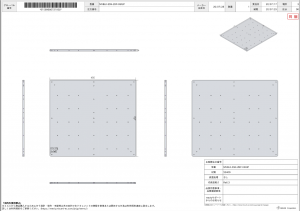

| Interior | Exterior | ||

| Product packaging | Simple 2D diagram | Multiple | Single |

|

|

|

|

| Includes simple 2D diagrams 2 layers of bubble wrap around each side The product label will be affixed to the outside before sending. | Sent in a box or bubble wrap bag. | ||

Long and heavy products may be delivered separately on pallets depending on the size or quantity. The customer will need to use a forklift to receive the products and dispose of the pallets. We do not ship heavy items overseas.

pallet + Rolled corrugated cardboard