- HELP

- Technical Information

- Sheet metal

- Accuracy and Machining Specifications

- Quality Control of Nut Mounted Products

Quality Control of Nut Mounted Products

Regarding the appearance of nut mounted products

|

|

|

|

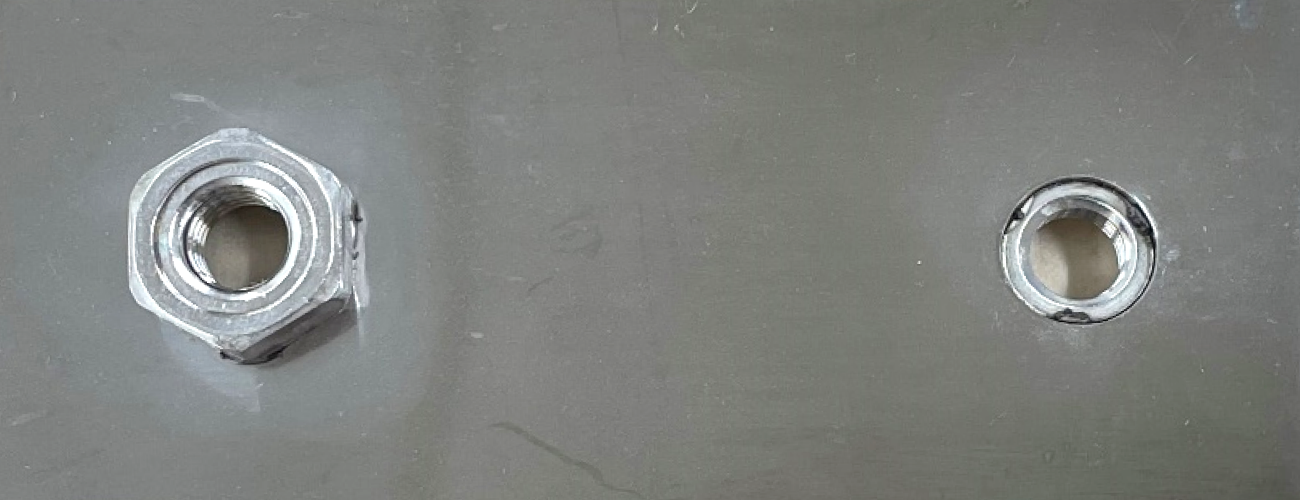

Product with press-fit nut

- Low Carbon Steel (Cold Rolled) with Electrolytic Zinc Plating, Hot Zinc Plating, 5052 AL Alloy Pre-Finish, Clear Anodize and 5052 AL Alloy Pre-Finish, Black Anodize may have some plating peeling due to nut mounting.

- Installation of nuts near the edge of the plate may cause the edge to swell.

|

|

|

|

|

|

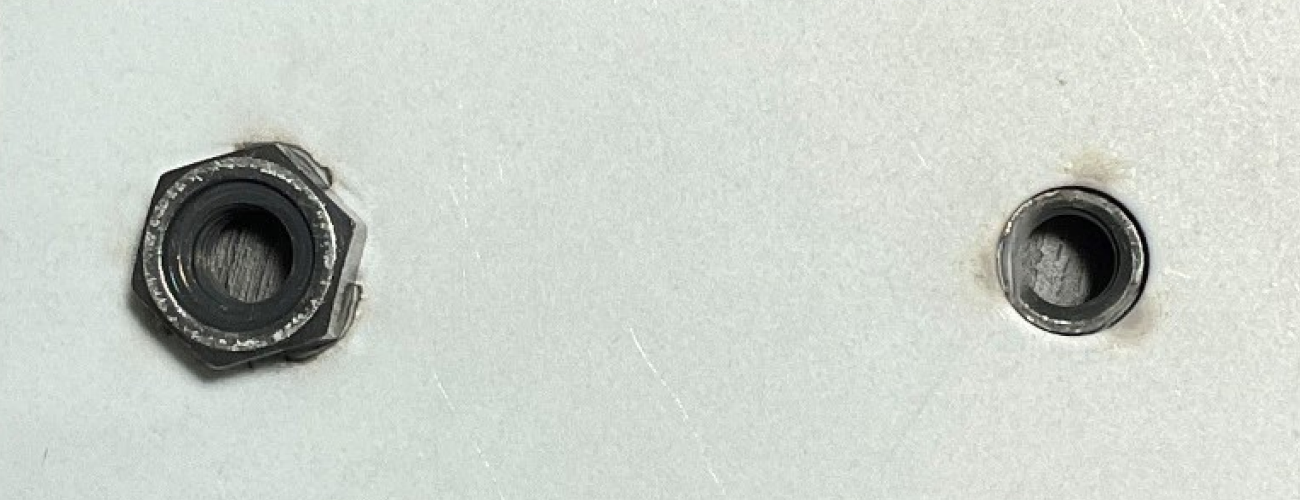

Product with weld (spot) nut

- For products with spot-welded nuts on steel materials,remove burns by using a file or similar tool. Scratch marks may appear due to the filing.

- Low Carbon Steel (Cold Rolled) with Electrolytic Zinc Plating and Hot Zinc Plating may have some plating peeling due to nut mounting.

Finish marks may remain.

Also, polishing to remove burns is not performed because it causes plating to peel off.

Spot-welded nuts on stainless steel will be removed the burn marks by electrolytic polishing. - The projection part of weld nut may be eluted, but the following items are inspected to confirm that there is no problem with tightness.

- pass through.

- projection part is not convex more than the material thickness.

Regarding the Strength Warranty for Nut mounted Products

Product with press-fit nut

- We do not guarantee the strength of products with press-fit nuts, but we will ship them after confirming that there are no problems with fastening.

Product with weld (spot) nut

- We do not guarantee the strength of products with weld (spot) nuts, but we will ship them after confirming that there are no problems with fastening.In addition, periodic evaluations are conducted in accordance with JIS B1196.