- HELP

- Technical Information

- Welded Sheet Metal

- Accuracy and Specifications

- Welding Distortion/Warpage

Welding Distortion/Warpage

Warpage and distortion after welding

We will correct significant warping or distortion as much as possible before shipment; however, we cannot guarantee complete removal of warping or distortion.

Furthermore, if significant distortion due to welding is anticipated prior to manufacturing, or if severe distortion persists after manufacturing despite corrective measures, leaving significant residual warping, meviy Support may contact you before shipment.

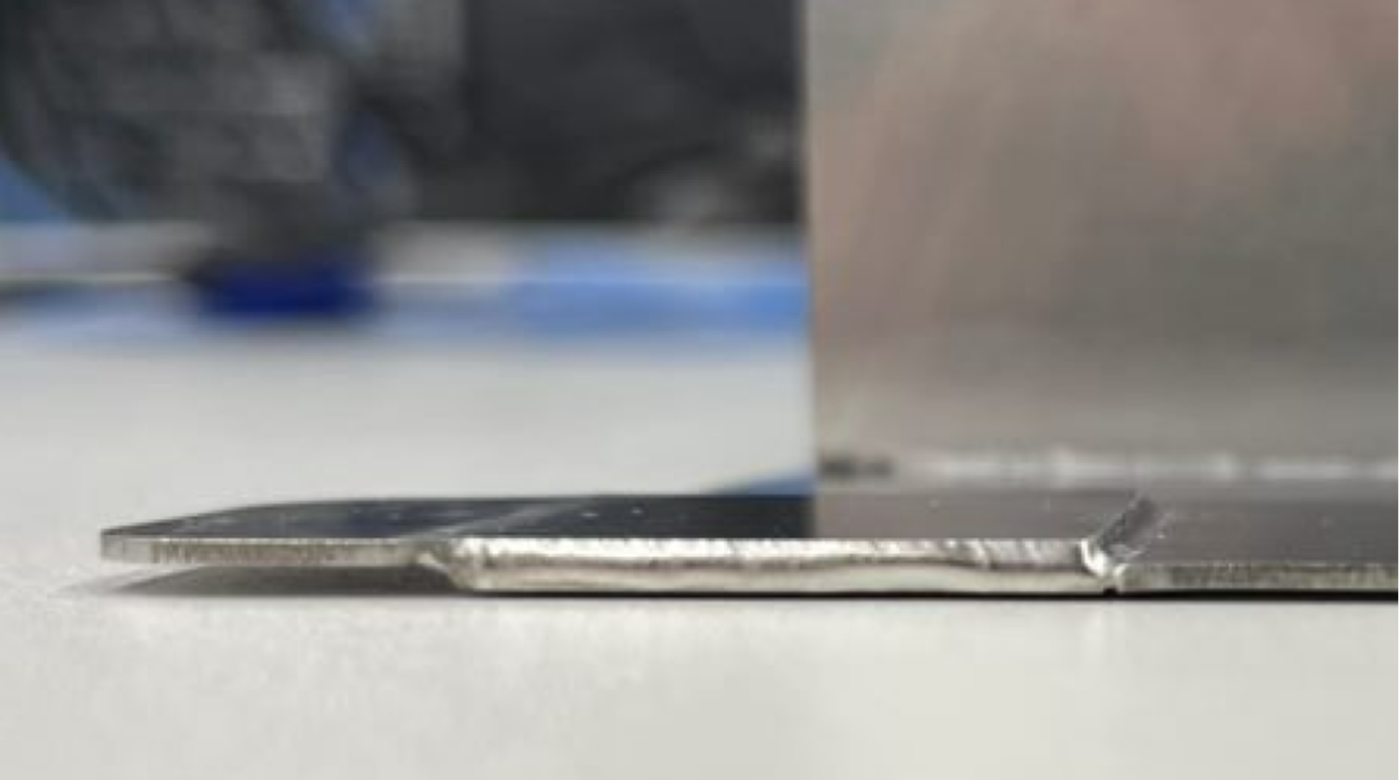

Example: warping caused by welding

Example:after warping correction

■Pre-shipment inspection items

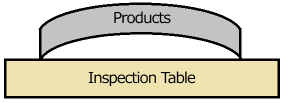

We visually inspect areas such as those marked with red arrows in the diagram below to confirm that no residual warping remains that deviates from the dimensional accuracy specifications for plate welding.

If significant residual warpage remains, meviy support may contact you regarding shipment approval.

Examples of warping/distortion inspection points at shipment

Tip

- Continuous arc welding tends to cause greater warping and distortion. This can be mitigated by switching to laser welding or adopting intermittent welding.

- Welding overlapped flat plate surfaces using spot welding can reduce warping and distortion. By clicking the [Edit Welding Information] button and checking “Spot weld overlapping flat plate areas,” we can provide a quote using spot welding.

- If you wish to minimize warping and distortion as much as possible, please indicate this in the Additional Instructions field and use the “Request Quote from meviy Support” option.