- HELP

- Technical Information

- Welded Sheet Metal

- Accuracy and Specifications

- Leak Test Method and Warranty Coverage

Leak Test Method and Warranty Coverage

Types of Leak Tests

Depending on the material and product shape, either a dye penetrant test or a snoop test will be selected and performed at the factory.

If you require a water-filling test, please specify this request in the Additional Instructions field and request a quote from meviy Support.

Color Check

The color check test method is described below.

- ①Remove any debris adhering to the product

- ②Apply color check to the welded area

- ③Apply the developer to the back side where the color check was applied

- ④Leave for approximately 30 minutes

- ⑤Visually inspect the weld area from the weld side for any red color reaction (leakage).

*During color checks, depending on the shape, the developer may flow around from the back side at the product edges or plate thickness surfaces. Therefore, even if there are no abnormalities in the weld quality, a red reaction may appear at the edges.

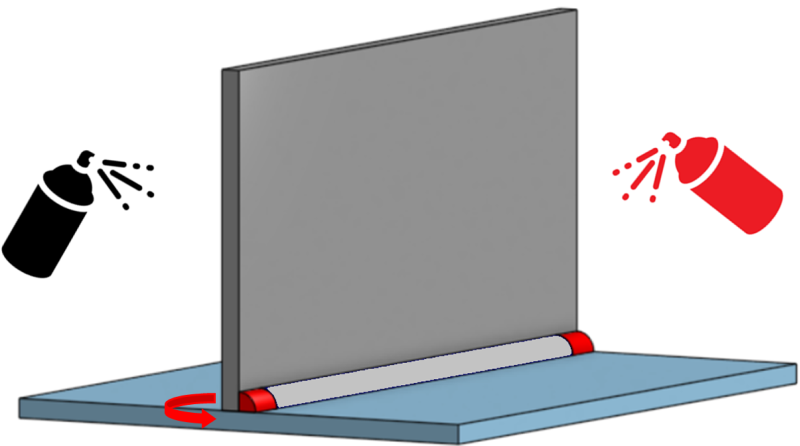

Schematic showing developer seeping into edges and causing red reactions at edges

Snoop Test

The test method for the Snoop test is described below.

- ①Remove any debris adhering to the product

- ②Apply Snoop solution to the welded area

- ③Blow air from the back side of the coated weld area

- ④Visually inspect for the presence of bubbles

*1 Spray for approximately 10 seconds per welded area to confirm

Scope of Leak Test Warranty

Applicable Product Usage Environments

- Products used indoors at temperatures between 10°C and 30°C

- Products where no pressure is applied to the welded area

- Products handling water and oil at temperatures between 11°C and 49°C

- Applications involving the temporary storage or discharge of water and oil

Product usage environments not covered by warranty

- When used outside the indoor temperature range of 10°C to 30°C (e.g., in freezers or boiler rooms)

- When used under pressure at the welded joint

- When used with fluids other than water and oil (e.g., corrosive liquids such as sulfuric acid or liquid nitrogen)

Product Appearance After Leak Testing

During the color check, if a red reaction appears where the penetrant and

developer come into contact by penetrating the welded joint, the product is judged

to have a leak and will not be shipped.

Products that pass the leak test will have the penetrant and developer used in the color check wiped off before shipment.

Depending on the product shape, the dye color (red or white) may remain in areas

where wiping is difficult or on minor irregularities on the weld bead.

However, this does not affect the quality assurance of leak-free products.

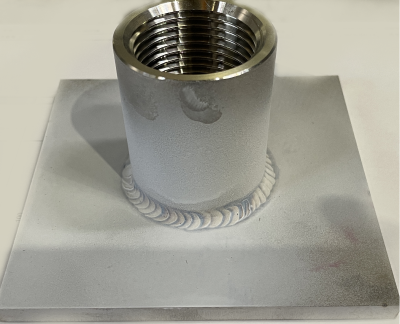

Appearance before wiping

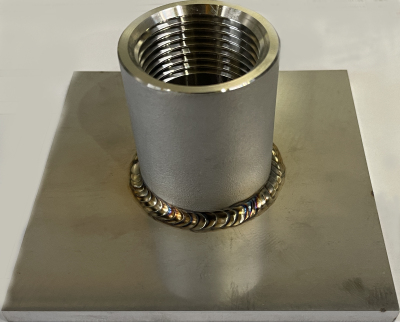

Appearance after wiping