- HELP

- Technical Information

- Welded Sheet Metal

- Design Guidelines

- Determination and Recognizable Size of Weld Locations

Determination and Recognizable Size of Weld Locations

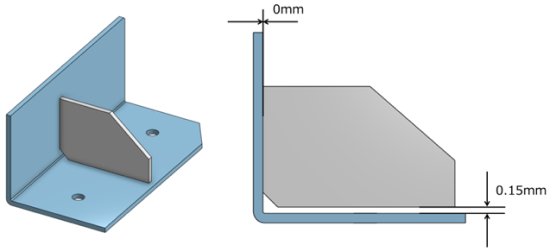

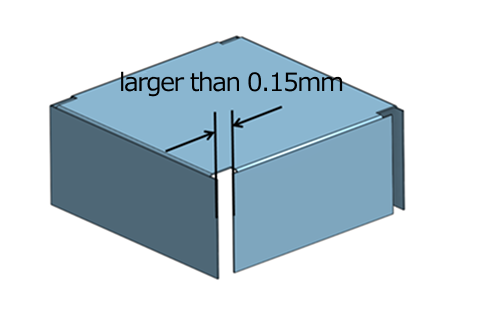

In Welded Sheet Metal services, areas where the distance between elements in the 3D model is within 0.15 mm are detected and identified as weld locations. Please confirm the following for areas identified as weld locations and those not identified.

Locations determined as welded areas

3D models composed of multiple solids

3D models composed of a single solid

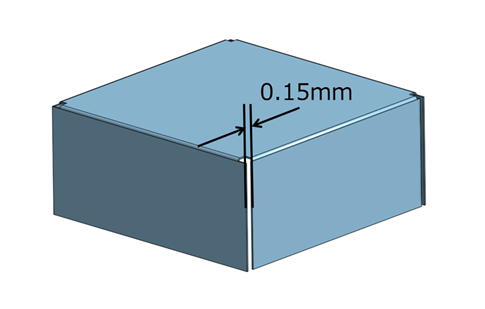

For shapes formed by a single sheet metal part, areas with gaps of 0.15mm or less are recognized as welded joints.

Tip

-

For shapes formed from a single sheet metal part, slit sections within 0.15mm are judged as weld points. Welding exemption cannot be selected.For areas where welding is not required, add slits with a width greater than 0.15mm.

-

For the box shown in the left diagram, the corners of the box are also subject to welding.*Modeling conditions: The size of the cutout must be within twice the plate thickness (per side), and the angle where the bend and weld intersect must be 90 degrees or greater. It will also be highlighted in the 3D viewer. For details, please refer to the “Basic Modeling Rules“.

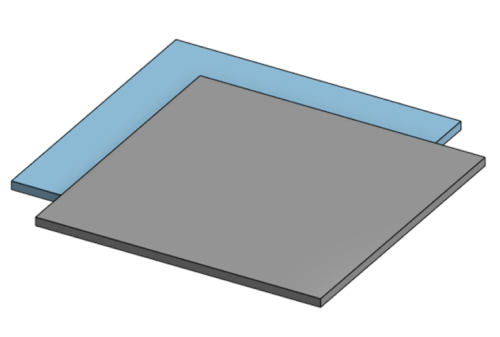

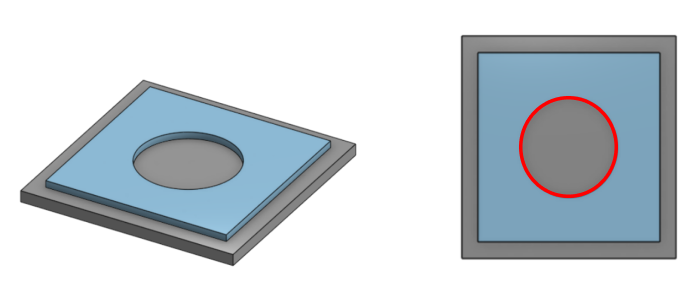

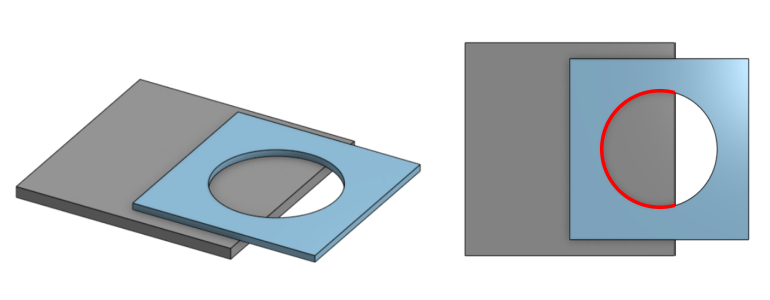

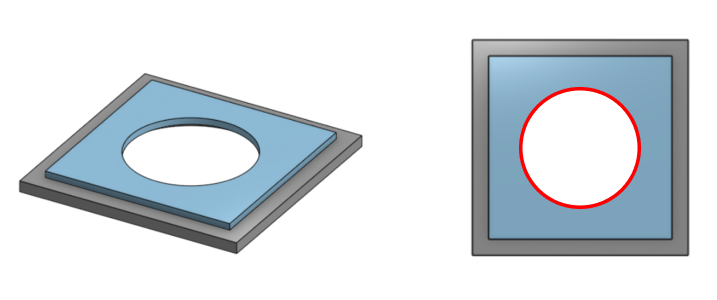

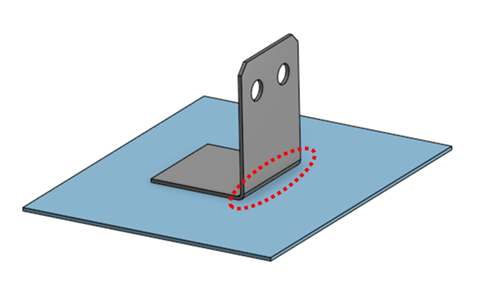

Overlapping plate flat surfaces

Overlapping plate flat surfaces are recognized as weld or spot weld locations along the outer perimeter of the overlap.

| Models with holes in square members |

|

|

| Models with holes in both members |

|

Holes present in overlapping flat plate surfaces

| Hole type | Size determined as a welded joint |

|---|---|

| Round hole |

|

| Long Hole | Long hole tip

|

| Angle holes |

|

Areas not identified as welded sections

For 3D models composed of multiple solids, areas where the distance between solids exceeds 0.15mm

Areas where the distance between solids exceeds 0.15mm cannot be recognized as weld points.

3D models composed of a single solid with gaps exceeding 0.15mm

For shapes formed by a single sheet metal part, areas with gaps larger than 0.15mm cannot be recognized as welded areas.

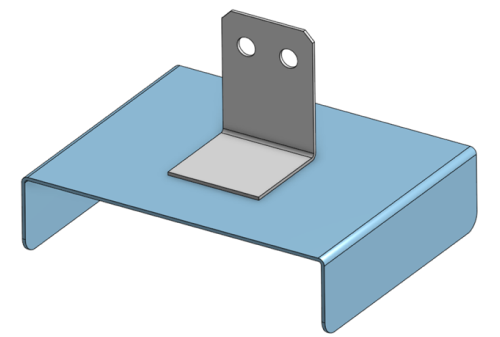

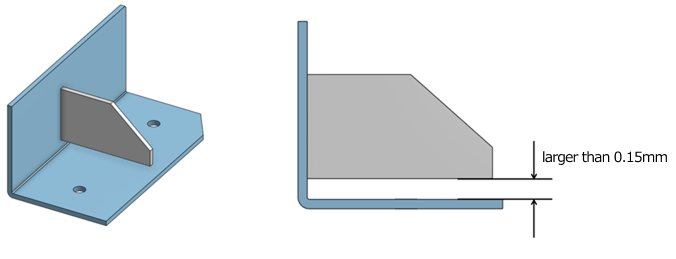

Bent edges on welded sections formed by overlapping plate planes

- As shown in the left diagram, in a 3D model where the flat surfaces of an L-shaped part are overlapped, the edge of the L-shaped bend cannot be recognized as a weld location.

- Edges without bends are recognized as weld points.

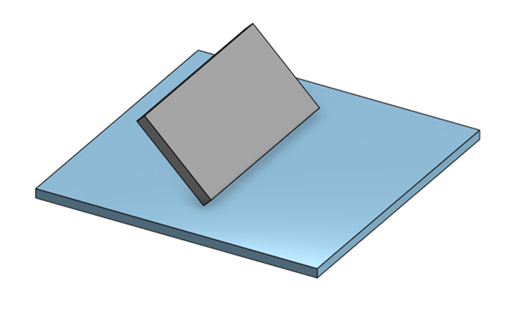

Diagonally arranged plate parts

Two solids positioned diagonally cannot be recognized as welded areas.

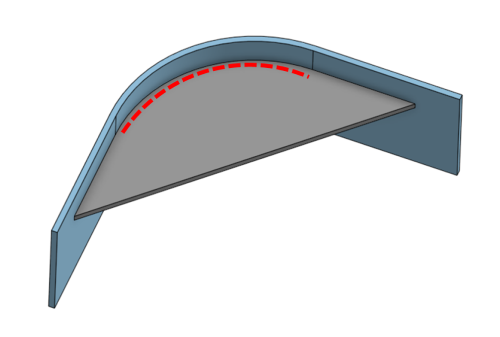

Curved surface contact points

Curved surfaces, such as the inside of a bend, cannot be recognized as weld points regardless of the distance between solids.