- HELP

- Technical Information

- Welded Sheet Metal

- Applicable Parts/Materials

- Material, Surface Treatment

Material, Surface Treatment

- Materials and surface treatments supported by our Welded Sheet Metal service are as follows.

- 〇: Automatic quotation possible, △: Automatic quotation not possible, but manual quotation by meviy Support is possible

- *For details on welding types and finishing methods, please refer to “Instructions and Details for Welding Information“.

| Material: Ferrous Metals | Surface Treatment | Sheet Thickness *1 | Standard welding: Arc welding, Laser welding | Spot welding | |

|---|---|---|---|---|---|

| Welding finish:

Burn Mark Removal Only |

Welding finish:

Grinder finishing |

||||

| Low Carbon Steel (Cold/Hot Rolled) | – | 1.0 1.2 1.6 2.0 2.3 3.2 4.5 6.0 | 〇 | 〇 | 〇

~3.2mm |

| Painting/Coating *2 | – | 〇 | |||

| Electroless Nickel Plating | 〇 | 〇 | |||

| Black Oxide | 〇 | 〇 | |||

| Trivalent Chromate (Clear) | 〇 | 〇 | |||

| Trivalent Chromate (black) | – | 〇 | – | ||

| Low Carbon Steel (Hot Rolled) | – | 9.0 10.0 12.0 16.0 | 〇 | 〇 | – |

| Electroless Nickel Plating | 9.0 | 〇 | 〇 | – | |

| Black Oxide | 〇 | 〇 | – | ||

| Trivalent Chromate (Clear) | 〇 | 〇 | – | ||

| Low Carbon Steel (Cold Rolled) | Electrolytic Zinc Plating *3 | 1.0 1.2 1.6 2.0 2.3 3.2 | 〇 | – | 〇 |

| Material: Stainless Steel | Finishing Method | Sheet thickness | Standard Welding: Arc Welding, Laser Welding | Spot welding | |

|---|---|---|---|---|---|

Welding finish: Burn Mark Removal Only | Welding Finish: Grinder finishing | ||||

| 304 Stainless Steel | No.1 | 9.0 10.0 12.0 | 〇 | 〇 | – |

| 2B | 1.0 1.2 1.5 2.0 2.5 3.0 4.0 5.0 6.0 | 〇 | 〇 | 〇 ~3.0mm | |

| Single-Sided #400-Grit Polished *4 *5 | 1.0 1.2 1.5 2.0 3.0 | 〇 | 〇 | △ | |

| Single-sided hairline finish *4 *5 *6 | △ | △ | △ | ||

| 430 Stainless Steel | 2B | 1.0 1.2 1.5 2.0 3.0 | 〇 | 〇 | 〇 |

| Material: Aluminum | Surface treatment | Sheet thickness | Standard Welding: Arc Welding, Laser Welding | Spot welding | |

|---|---|---|---|---|---|

Welding finish: Burn Mark Removal Only | Welding finish: Grinder finish | ||||

| 5052 Aluminum Alloy | – | 1.0 1.2 1.5 1.6 2.0 2.5 3.0 4.0 5.0 6.0 | 〇 | 〇 | 〇 ~2.5mm |

| Clear Anodize | 〇 | 〇 | △ | ||

| Black Anodize | 〇 | 〇 | |||

| Black Anodize (matte) *7 | 〇 | 〇 | |||

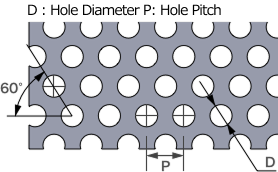

| Material: Perforated Metal | Hole Diameter × Hole Pitch *8 | Open Area Ratio | Sheet thickness | Standard welding: Arc welding, Laser welding | Spot welding | |

|---|---|---|---|---|---|---|

Welding finish: Burn Mark Removal Only | Welding finish: Grinder finishing | |||||

| ø2×3p | 40.3% | 1.0 | △ | △ | – |

| ø3×5p | 32.7% | 1.0 1.5 | △ | △ | – | |

| ø5×8p | 35.4% | △ | △ | – | ||

| ø8×12p | 40.2% | 1.5 | △ | △ | – | |

- *1 Plate thickness tolerance is ±10% as a guideline.

*2 All 14 colors are available. For details, please refer to “Types of Paint Color“.

Certain coated products (2 powder coating colors (5Y7.2/1.4, 5P9/1) , 7 solvent-based coating colors) are not available for plate thicknesses of 6mm or greater.

- *3 As this is a pretreatment agent, plating will not adhere to the treated surface.

- *4 Except for welded areas and their immediate surroundings, products are delivered with protective sheets (sheet surfaces only) applied.

- *5 The finish side will be the polished surface.

- *6 For hairline direction, please refer to the sheet metal manual “About Hairline Direction“.

- *7 Black Anodize (matte) is not available for cut-out shapes.

- *8 Refer to the diagram below for hole diameter and pitch specifications. However, the hole pitch direction is arbitrary.

- *9 Surface finish differences may occur between sheet metal parts and Welded Sheet Metal products. If this is unacceptable, please request a quote from your representative.