- HELP

- Technical Information

- Welded Sheet Metal

- Applicable Parts/Materials

- Quotation Requirements for Welded Parts with Different Plate Thickness

Quotation Requirements for Welded Parts with Different Plate Thickness

- We can also provide estimates for welded sheet metal parts composed of two or more different sheet thicknesses.

- Please refer to the following for the conditions under which quotations are possible.

Modeling Rules for Plates with Different Thicknesses

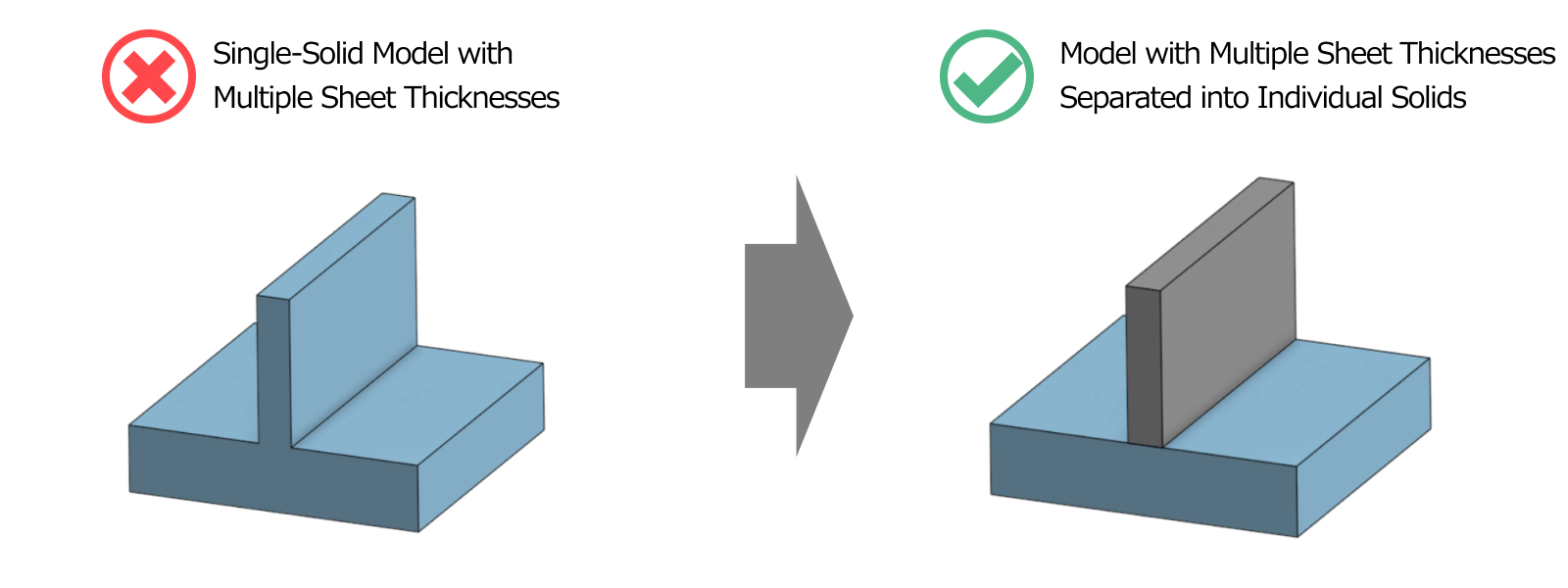

For Welded Sheet Metal parts composed of two or more sheet thicknesses, model each thickness as a separate solid.

Estimation-Supported Plate Thickness Combinations

There are restrictions on the number of plate thickness types that can be estimated. Please refer to the table below.

| Number of Plate Thickness Types | |

|---|---|

| Automatically Estimated | Up to 3 types |

| Estimated by meviy Support | Up to 5 types |

| Quotation not possible | 6 or more types |

- Please refer to the table below for the minimum and maximum combination ranges of material groups and plate thicknesses that can be automatically estimated.

- We do not support combinations of different materials across material groups.

| Material Group 1 | Sheet Thickness Combination Range | |||

|---|---|---|---|---|

| Arc welding, Laser welding | Spot Welding | |||

| Minimum | Maximum | Minimum | Maximum | |

Low Carbon Steel (Cold/Hot Rolled) Low Carbon Steel (Hot Rolled) *1 | 1.0 | 2.0 | 1.0 | 3.2 |

| 1.2 | 2.6 | 1.2 | 3.2 | |

| 1.6 | 3.2 | 1.6 | 3.2 | |

| 2.0 | 4.5 | 2.0 | 3.2 | |

| 2.3 | 6.0 | 2.3 | 3.2 | |

| 3.2 | 9.0 | 3.2 | 3.2 | |

| 4.5 | 10.0 | – | – | |

| 6.0 | 12.0 | – | – | |

| 9.0 | 16.0 | – | – | |

*1 For configurations containing components with plate thickness exceeding 6.0mm where solvent-based coating is selected for surface treatment, variations in plate thickness will only be accepted upon confirmation by the personnel responsible.

| Material Group 2 | Sheet Thickness Combination Range | |||

|---|---|---|---|---|

| Arc Welding, Laser Welding | Spot Welding | |||

| Minimum | Maximum | Minimum | Maximum | |

| Low Carbon Steel (Cold Rolled) (Electrolytic Zinc Plating) |

1.0 | 2.0 | 1.0 | 3.2 |

| 1.2 | 2.6 | 1.2 | 3.2 | |

| 1.6 | 3.2 | 1.6 | 3.2 | |

| – | – | 2.0 | 3.2 | |

| – | – | 2.3 | 3.2 | |

| – | – | 3.2 | 3.2 | |

| Material Group 3 | Sheet Thickness Combination Range | |||

|---|---|---|---|---|

| Arc welding, laser welding | Spot welding | |||

| Minimum | Maximum | Minimum | Maximum | |

|

304 Stainless Steel (2B)

304 Stainless Steel (No.1) |

1.0 | 2.0 | 1.0 | 3.0 |

| 1.2 | 2.5 | 1.2 | 3.0 | |

| 1.5 | 3.0 | 1.5 | 3.0 | |

| 2.0 | 4.0 | 2.0 | 3.0 | |

| 2.5 | 5.0 | 2.5 | 3.0 | |

| 3.0 | 6.0 | – | – | |

| 4.0 | 9.0 | – | – | |

| 5.0 | 10.0 | – | – | |

| 6.0 | 12.0 | – | – | |

| Material Group 4 | Sheet Thickness Combination Range | |||

|---|---|---|---|---|

| Arc welding, Laser welding | Spot Welding | |||

| Minimum | Maximum | Minimum | Maximum | |

| 304 Stainless Steel (Single-Sided #400-Grit Polished) *2 | 1.0 | 2.0 | – | – |

| 1.2 | 3.0 | – | – | |

| Material Group 5 | Sheet Thickness Combination Range | |||

|---|---|---|---|---|

| Arc welding, Laser welding | Spot Welding | |||

| Minimum | Maximum | Minimum | Maximum | |

| 304 Stainless Steel (Single-sided hairline finish) *2 | 1.0 | 2.0 | – | – |

| 1.2 | 3.0 | – | – | |

*2 304 Stainless Steel (Single-sided hairline finish) is available only for manual quote. Additionally, 304 Stainless Stee (Single-Sided #400-Grit Polished) requires a manual quotation request for products including spot welding.

| Material Group 6 | Sheet Thickness Combination Range | |||

|---|---|---|---|---|

| Arc Welding, Laser Welding | Spot Welding | |||

| Minimum | Maximum | Minimum | Maximum | |

| 430 Stainless Steel (2B) | ||||

| 1.0 | 2.0 | 1.0 | 3.0 | |

| 1.2 | 3.0 | 1.2 | 3.0 | |

| – | – | 1.5 | 3.0 | |

| – | – | 2.0 | 3.0 | |

| Material Group 7 | Sheet Thickness Combination Range | |||

|---|---|---|---|---|

| Arc welding, Laser welding | Spot welding | |||

| Minimum | Maximum | Minimum | Maximum | |

| 5052 Aluminum Alloy | 1.0 | 2.0 | 1.0 | 2.5 |

| 1.2 | 2.5 | 1.2 | 2.5 | |

| 1.5 | 3.0 | 1.5 | 2.0 | |

| 1.6 | 3.0 | 1.6 | 2.0 | |

| 2.0 | 4.0 | 2.0 | 2.0 | |

| 2.5 | 5.0 | – | – | |

| 3.0 | 6.0 | – | – | |

Regarding the range of machining limits for parts with different thicknesses

- The processing limits for plate-welded components with different plate thicknesses vary depending on the welding method.

- ・Arc welding, laser welding ⇒ The processing limit value of the component with the largest plate thickness in the product is the standard

- ・Spot welding ⇒ The processing limit value of the thinner component forming the welded area is the standard

- For details, refer to the Welded Sheet Metal design guideline “Range of Machining Limits“.

Regarding Shipment Dates for Parts with Different Sheet Thicknesses

- The shipping date for Welded Sheet Metal parts with different plate thicknesses is the standard shipping date for parts made with a single plate thickness plus one day.

- For details, refer to “Shipping Days” in the Welded Sheet Metal Applicable Parts/Materials.