- HELP

- Technical Information

- Welded Sheet Metal

- Applicable Parts/Materials

- Spot Welding and Finishing

Spot Welding and Finishing

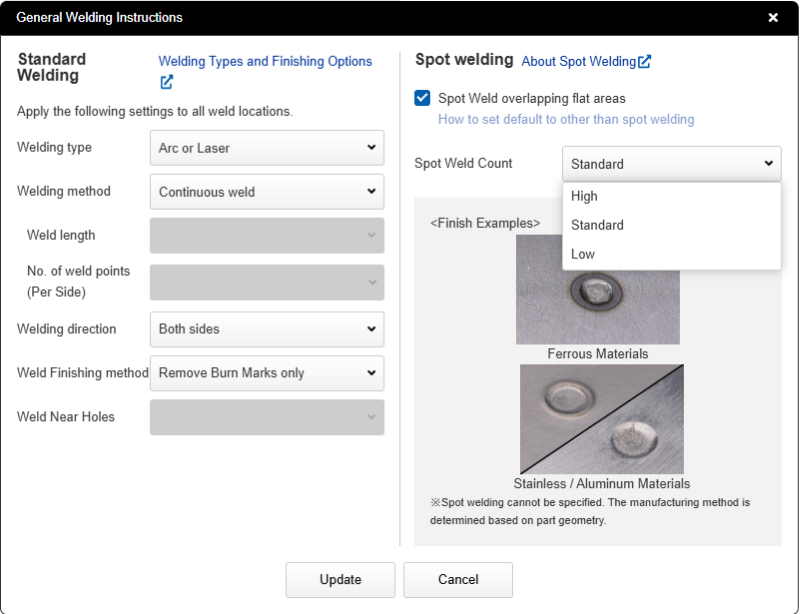

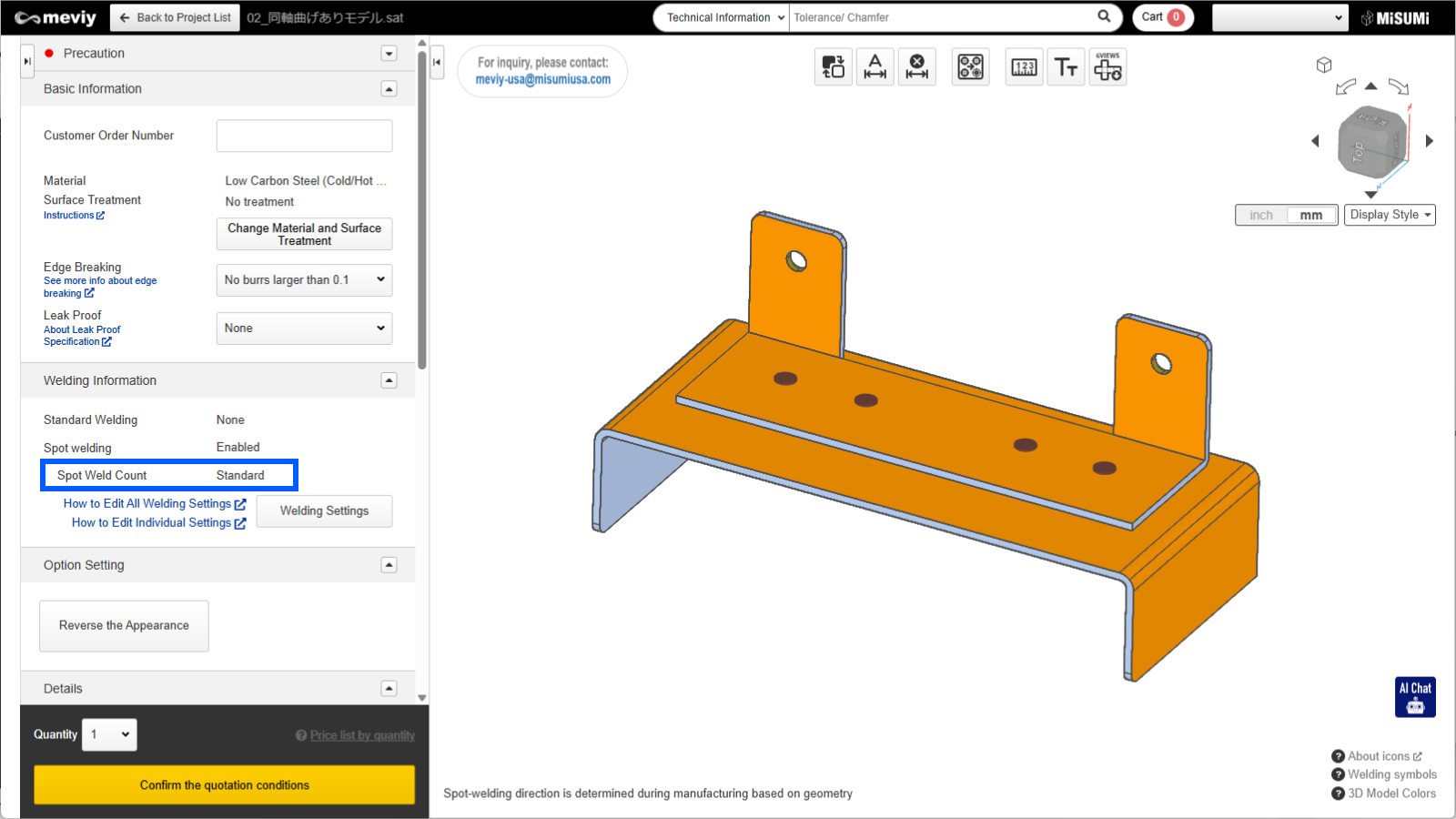

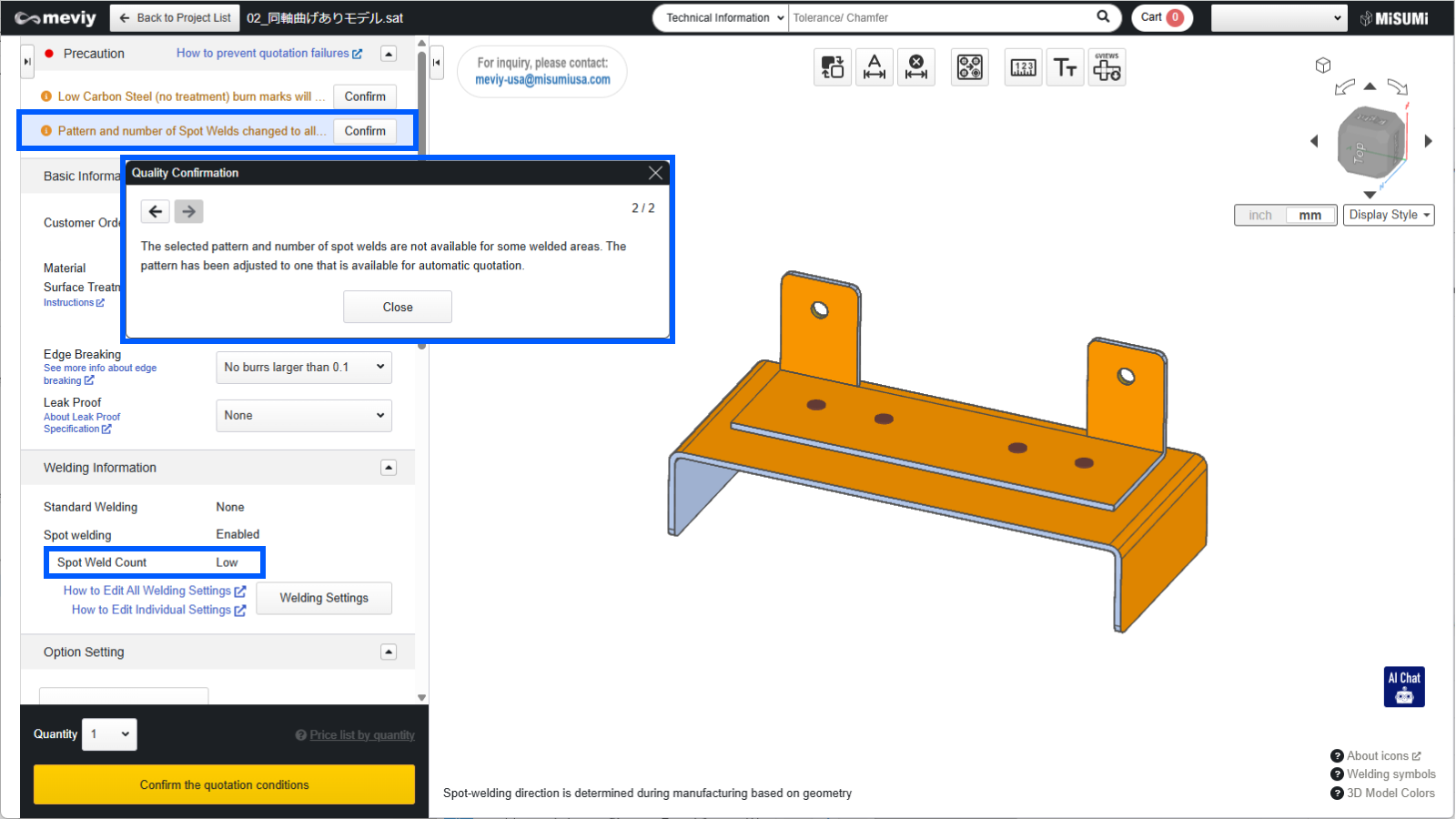

By checking the spot welding option in the overall welding information display field and updating, it is possible to estimate areas where two plate flat surfaces overlap as

spot welds. When spot welding is specified, it is applied to all locations where spot welding is possible.

*If the area where two plate surfaces overlap is too small to meet the single-point processing limit value, it will be judged as ineligible for spot welding processing. Even if spot welding is checked in the Overall Welding Information field, that location will be estimated as standard welding.

Even if the spot welding checkbox is selected in the welding information display field, this area will be estimated as conventional welding. Refer to “Range of Machining Limits” for spot welding processing limits.

Spot Weld Processing

Processing Method

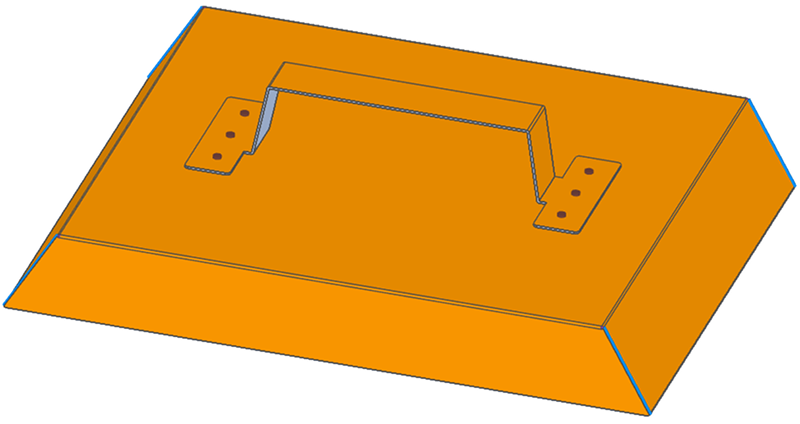

Depending on the product shape, either fixed-position or table-type spot welding machines are used for processing. The machine type is determined at the manufacturing plant.

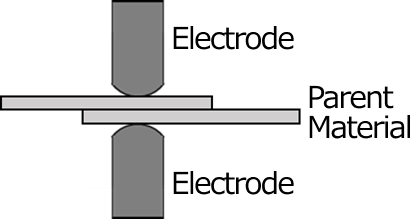

The appearance of spot weld marks differs slightly. With fixed-type machines, indentations form as spot marks on both sides of the overlapping area between two plates.

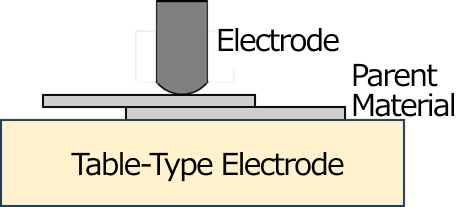

However, with table-type machines, no indentations form on the surface placed flat against the table electrode.

Note that the depth of the indentation tends to be greater with the table-type machine.

If you have a specific spot welding machine in mind, please indicate it in the additional instructions section and request a quote from our representative.

Number of Spot Patterns

If you wish to specify the exact number of spot welds per welded surface, please indicate this in the Additional Instructions field and use the party’s quotation service responsible.

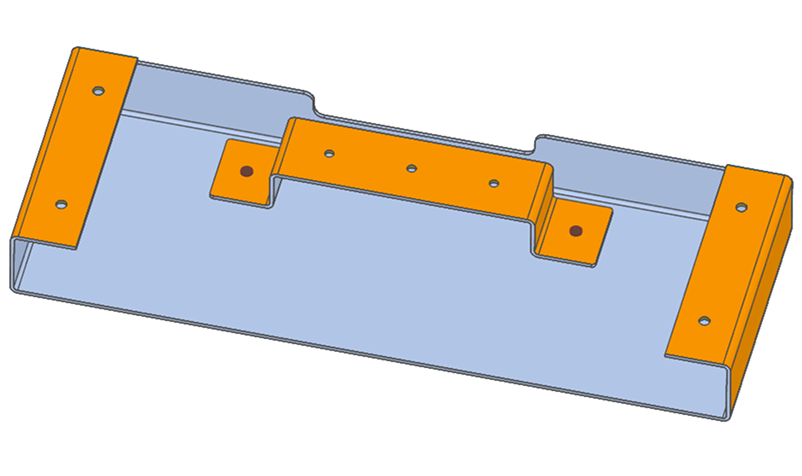

- Standard: The default setting is Standard.

- High: The number of spot welds per panel will be increased.

- Low: meviy will arrange the spots to reduce the number of spot welds per welded surface.

Caution

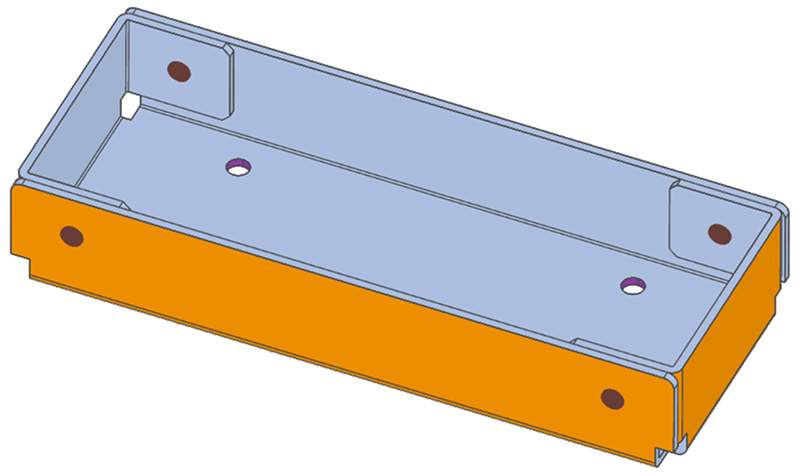

Number of spot weld locations recognized per side

When there are two or more spot weld points per side of a welded section, it is subject to automatic estimation

When only one spot weld is recognized per surface, automatic estimation applies if the following conditions are met; otherwise, manual estimation by meviy Support is required due to strength insufficiency concerns.

- When the spot welded area is within the same part and has only one spot weld (see Figure ① below)

- When it is a surface weld between two parts, but there are other welded areas connecting those two parts besides that surface weld (Fig. 2)

* However, if the other welding points are also single-spot fillet welds, an additional condition for automatic estimation is that the two fillet welds must not be coaxial.

Spot Weld Finishing

Finishing

- Spot weld finishing is performed using specific methods based on material properties, regardless of the welding finish type selected for conventional welding (arc welding, laser welding).

- Refer to the “Finish Processing Standards” for details.