- HELP

- Technical Information

- Welded Sheet Metal

- Welding Standards

- Finish Processing Standards

Finish Processing Standards

Finishing Type (Arc Welding, Laser Welding)

Scale Removal Only

“Burn Mark Removal only” removes weld scale using the specified method. However, for Low Carbon Steel (Cold/Hot Rolled), Low Carbon Steel (Cold Rolled) (Electrolytic Zinc Plating), and 5052 Aluminum Alloy materials, weld scale embedded deep inside welds cannot be reached by tools and will remain.

- Low Carbon Steel (Cold/Hot Rolled), Low Carbon Steel (Cold Rolled) (Electrolytic Zinc Plating) , and 5052 Aluminum Alloy are processed using a grinder.

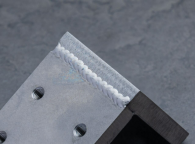

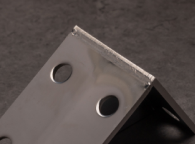

- Within tool-accessible areas, not only weld burn but also the weld bead area is ground; however, complete flattening of the weld bead is not performed.

- For weld beads and weld burn marks in areas inaccessible to tools, soot removal is performed using a cloth cleaner or similar.

- If complete flattening of the weld bead is desired, please select the grinding finish option.

- 304 Stainless Steel (2B), 304 Stainless Steel (No.1), 304 Stainless Steel (Single-Sided #400-Grit Polished) ,430 Stainless Steel (2B) undergo electrolytic polishing to remove weld burn.

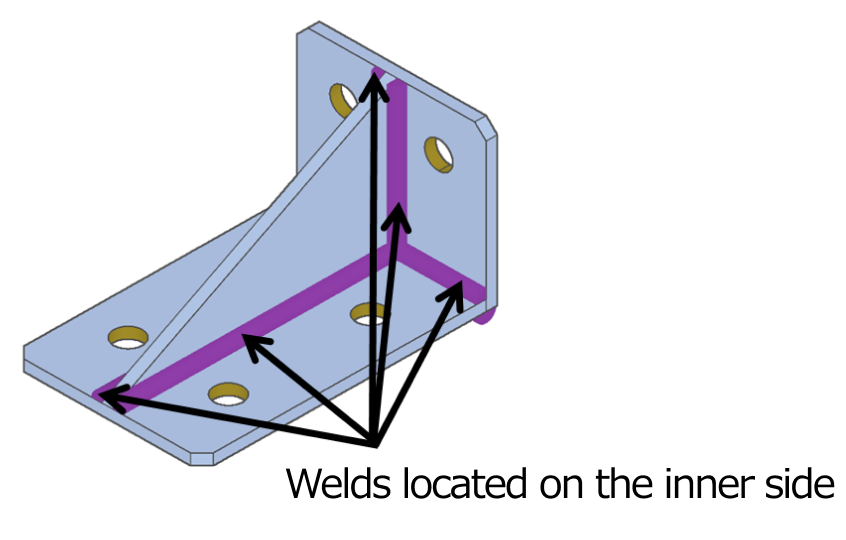

- Weld burn treatment targets include the inner weld area. The weld bead itself remains untouched. No overall surface polishing is performed after burn removal treatment.

- If you desire surface grinding on the visible side after burn removal treatment for 304 Stainless Steel (Single-Sided #400-Grit Polished), please select the grinder finish option.

Grinder Finish

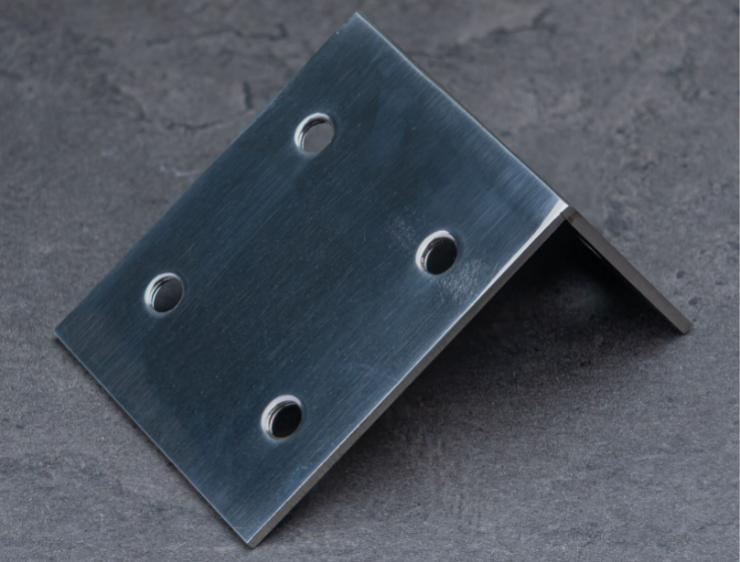

5052 Aluminum Alloy Outer Surface

304 Stainless Steel (2B) Outer Surface

430 Stainless Steel (2B) Outer Surface

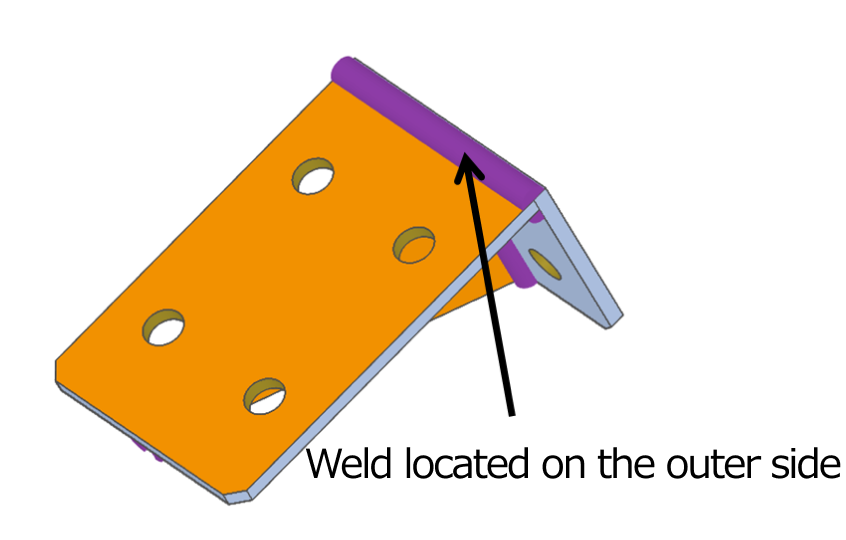

Finishing Areas (Arc Welding, Laser Welding)

Finishing Methods by Material and Surface Treatment (Arc Welding, Laser Welding)

Finishing Compatibility Chart by Material and Surface Treatment

| Material | Burn Mark Removal only | Grinder finish | ||||

|---|---|---|---|---|---|---|

|

Outer

Weld scale |

Inner

Weld burn (scale) |

Weld bead residue |

Outer side Weld burn (scale) |

Inside

Weld burn (scale) |

Weld bead residue | |

|

Low Carbon Steel (Cold/Hot Rolled)

Low Carbon Steel (Cold/Hot Rolled) + Various Plating

*Excluding Trivalent Chromate (Black)

chromate (black) |

Grinder processing

(Only near welded

areas) |

Rags, cleaners, etc.

Soot removal |

Outer side: None

Inner side: Yes |

Grind with a grinder

(Near welded areas

only) |

Cloth cleaner, etc.

Soot removal |

Outer side: None (flat)

Inner side: Yes |

| Low Carbon Steel (Cold/Hot Rolled)

+

Trivalent Chromate(Black) |

– | After grinding, polish entire surface | ||||

| Low Carbon Steel (Cold/Hot Rolled)

+

Various painting/Coating |

– |

Grind with a grinder

(Only near welded

areas) |

||||

| Low Carbon Steel (Cold Rolled)

(Electrolytic Zinc Plating) |

Grinder treatment

(Only near welded

areas) |

Wipes, cleaners, etc.

Soot removal |

Outer side:

None

Inner side: Yes |

– | ||

|

304 Stainless Steel (No.1)

304 Stainless Steel (2B)

430 Stainless Steel (2B) |

Electropolishing | Electropolishing |

Outer: Yes

Inner: Yes |

Electropolishing | Electropolishing |

Outer: None (Flat)

Inner: Yes |

| 304 Stainless Steel (Single-Sided #400-Grit Polished) | Electropolished and ground, then buffed to a #400 or higher finish on the visible surface | |||||

| 5052 Aluminum Alloy

+

Various Anodized Finishes |

Grinding

(only near welded

areas) |

Wipes, cleaner, etc.

Soot removal |

Outer: None

Inner: Yes |

Grind with a grinder

(Only near welded

areas) |

Cloth cleaner, etc.

Soot removal |

|

- ・Inside: Present ⇒ Weld bead remains unground (may be ground within tool access range)

- ・Outer side: None (flat) ⇒ Weld bead has been ground away, not protruding relative to surrounding surface

- ・Outer: None ⇒ Weld bead has been ground, but flatness relative to surrounding surfaces is not guaranteed

Materials/Surface Treatments Requiring Additional Specific Finishing Methods

- When selecting grinder finish, the visible surface is finished with #400 or higher buff polishing.

304 Stainless Steel (Single-Sided #400-Grit Polished) Appearance after grinder finish

- Only grinder finish is available.

- Similar to other plated products, after grinding finish prior to surface treatment, the entire surface is polished using a double-action sander before plating.

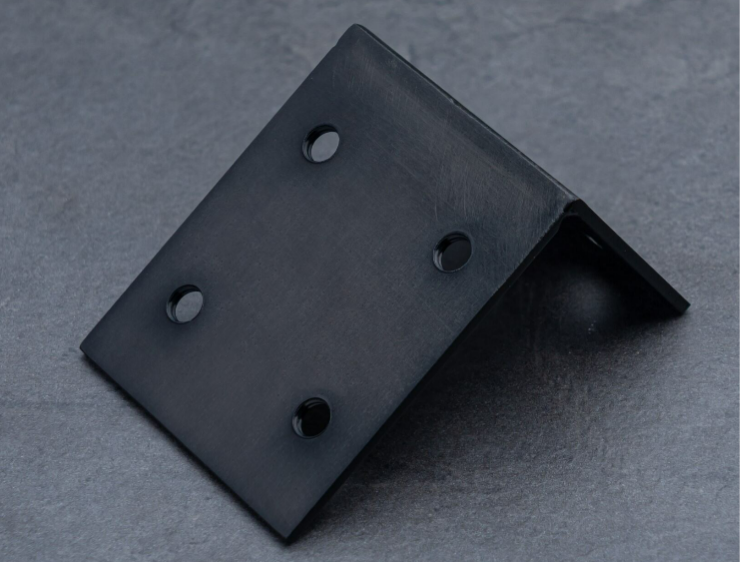

Low Carbon Steel (Cold/Hot Rolled) + Trivalent Chromate (Black) Appearance after Grinder Finishing

Spot Weld Finishing Method

Spot weld finishing is performed using a fixed method based on the material, regardless of the selection in the welding information field.

For example, even if grinding finish is selected in the welding information indicator field, grinding is not performed on the spot weld marks, so the spot weld marks remain as-is at shipment.

Finishing Methods by Material

- No weld burn removal processing is performed for spot welds; spot weld marks are left as-is for shipment.

- However, weld burn marks caused by temporary fasteners will be processed using a grinder within the range accessible by tools.

- No weld burn removal processing is performed for spot welding; products are shipped with spot weld marks remaining.

- To preserve the coating, no burn removal processing is performed on areas with weld burn caused by temporary stops.

- Weld burn marks from spot welding are removed by electrolytic polishing. Products are shipped with the spot weld marks remaining.

- No burn removal processing is performed for weld burns associated with spot welding. However, only the area near the spot weld marks is processed with a grinder to ensure no protrusions remain relative to the surrounding area.

- No treatment is performed on weld burn marks caused by temporary stops.