- HELP

- Technical Information

- Welded Sheet Metal

- Welding Standards

- Appearance After Welding and Finishing Processes

Appearance After Welding and Finishing Processes

Overall Product Appearance

Appearance of Plated Parts

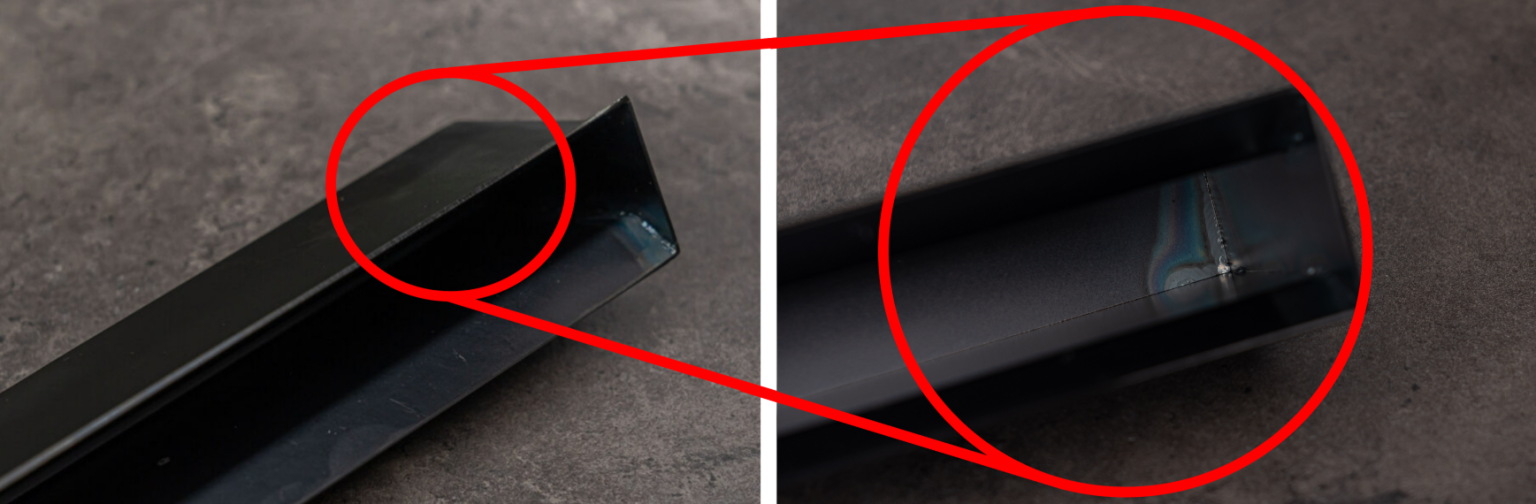

In areas where plating solution flow is restricted, such as corners of fully enclosed box shapes, color variations (red-framed areas in the figure below) may occur.

As a countermeasure, we recommend modeling through holes near these areas.

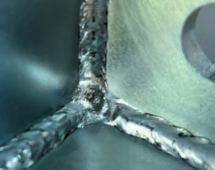

Example of color unevenness occurring at the corner of a box shape

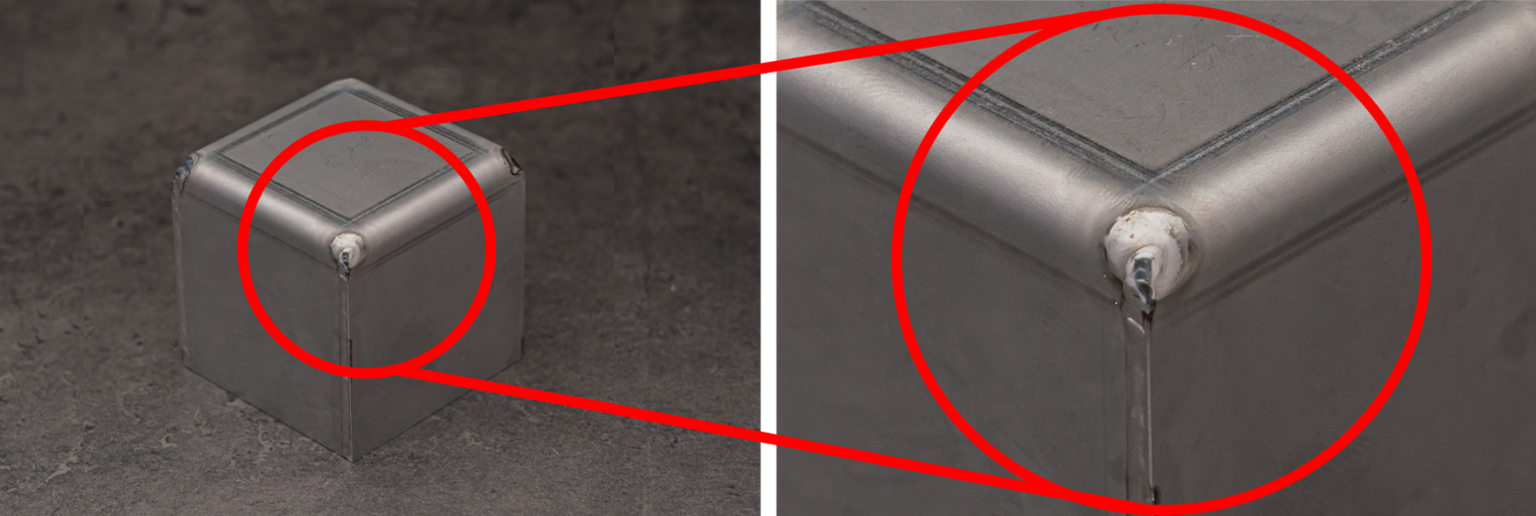

Appearance of box-shaped corner

- For box-shaped corners, weld and fill holes from the outer side at locations indicated by purple spherical highlights in the 3D viewer.

- For criteria determining whether to fill corners of box shapes in meviy, refer to Basic Modeling Rules.

Box shape corner hole filling status

Box-shaped corners with unfilled holes

Appearance of the welded area

Splatter

Splatter generated during welding is removed before shipment.

- For Ferrous Metals and aluminum-based materials, removal marks may remain to an extent that does not affect the surface.

- Stainless steel materials are shipped without any spatter removal marks.

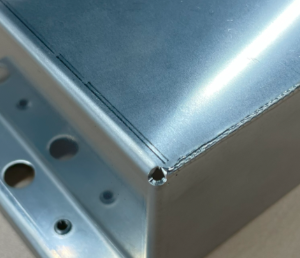

〇 Ferrous-based materials

Ferrous materials After spatter removal

× Example without spatter removal

Ferrous Materials Before Spatter Removal

Weld bead burrs

We confirm that no burrs remain on the weld bead before shipping.

Cracks

We confirm that there are no cracks in the weld bead area before shipping.

Undercut and Overlap

We confirm the absence of undercut and overlap before shipping.

・Undercut

・Overlap

Caution

Arc strike

We confirm the absence of arc strike before shipping.

Example of Arc Strike

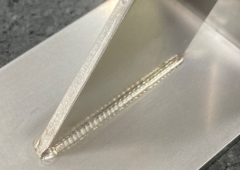

Weld Bead Slag

When performing Semi-automatic (CO2) arc welding on thick iron-based plates, slag may form on the weld bead.

We remove as much slag as possible before shipping, but complete removal may not always be possible.

Note that slag does not indicate a functional defect in the weld bead; however, surface treatment tends to adhere less readily to weld bead areas containing slag.

If you purchase thick iron-based plates without surface treatment from meviy and plan to perform surface treatment in a subsequent process, please specify that slag removal is required in the Additional Instructions field and request this via the responsible party’s quotation.

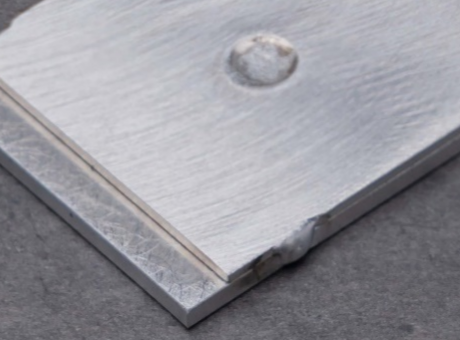

Example of poor surface treatment adhesion due to slag formation (black spot area)

Temporary welding marks (arc welding, laser welding)

When performing welding operations using arc welding or laser welding, depending on the shape, tack welding may be performed before the main welding operation. In such cases, tack welding marks may be visible in some areas, but this does not cause any functional issues.

Furthermore, finishing processes equivalent to those for the main weld are also performed on the temporary weld areas.

Temporary weld marks

Temporary weld marks (spot welding)

Temporary welding may be performed to prevent part misalignment during spot welding.

Temporary welding is performed at several points on the plate thickness surface (side surface). If this is not possible, it is performed at inconspicuous locations on the side surface.

Temporary welding for A5052 material involves stick welding, resulting in slightly larger weld sizes compared to iron or stainless steel.

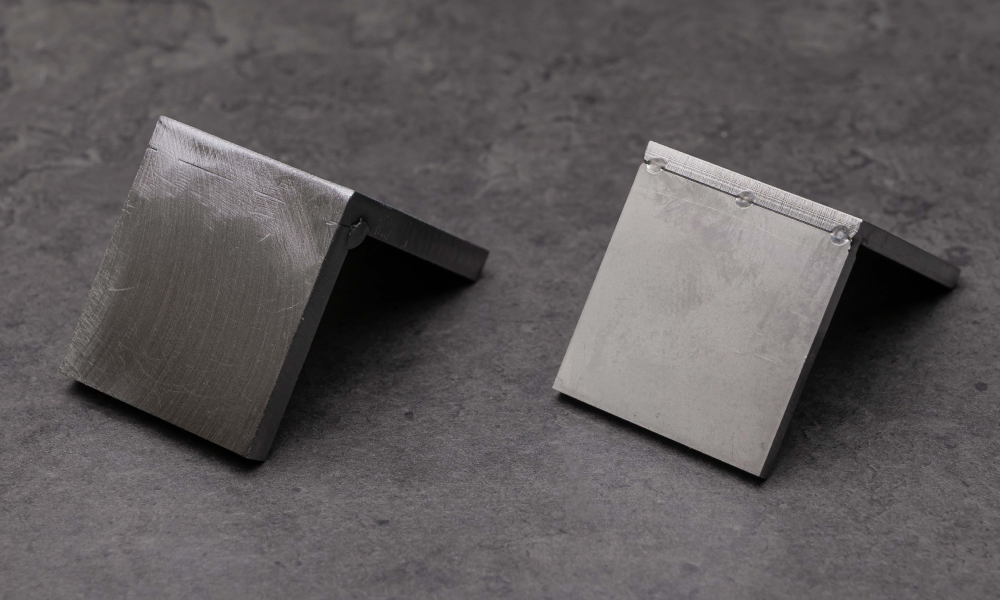

Low Carbon Steel (Cold/Hot Rolled)

304 Stainless Steel(2B)

5052 Aluminum Alloy

Spot Weld Marks

Spot weld marks that are close to circular in shape are considered normal spot welding workmanship.

Spot weld marks are inspected for shape before shipment.

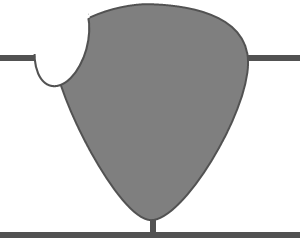

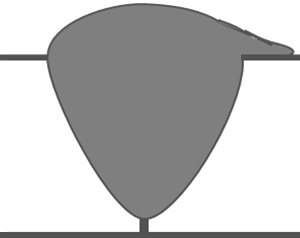

○ Good example

× Bad Example