- HELP

- Technical Information

- CNC Turning

- Design Guidelines

- Example Errors for CNC Turning

Example Errors for CNC Turning

- When uploading a model to meviy, a “Quotation failure” error may occur.

Below is an overview of why these errors occur and how to resolve them,as well as some example errors.

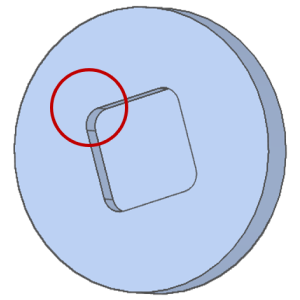

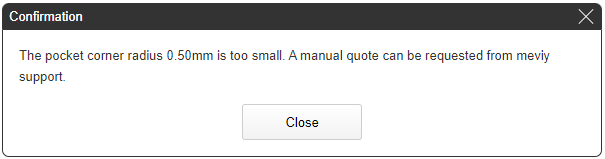

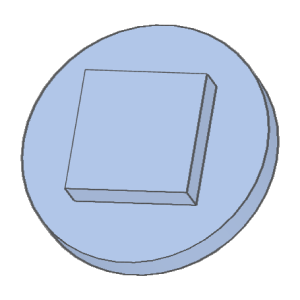

Case 1: Pocket Corners

*This message may appear for cases other than the following examples.

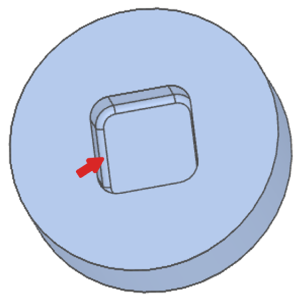

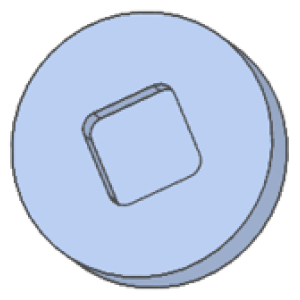

Pocket Corners

| Cause | In some cases, sharp pocket corners cannot be machined with an end mill and quotation is not possible. |

| Solution | Add a radius to each sharp corner in the pocket to allow for the tool radius. Quotation is possible. |

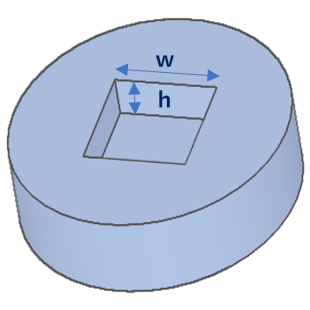

The tool used will vary depending on the width and depth of the pocket. Refer to the table below for the corner radius required for the size of the pocket.

- *Please use the table as a reference only as the required radius may vary depending on the shape.

Reference values for Radius modeling

| Width (w) | Depth (h) | Radius |

|---|---|---|

| 2≦w<3 | 6 | R1 |

| 3≦w<4 | 9 | R1.5 |

| 4≦w<5 | 12 | R2 |

| 5≦w<6 | 20 | R2.5 |

| 6≦w<8 | 24 | R3 |

| 8≦w<10 | 32 | R4 |

| 10≦w<12 | 40 | R5 |

| 12≦w<16 | 48 | R6 |

| 16≦w<20 | 64 | R8 |

| 20≦w | 80 | R10 |

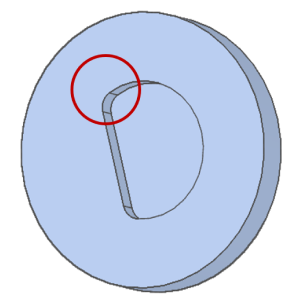

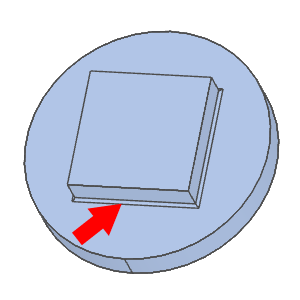

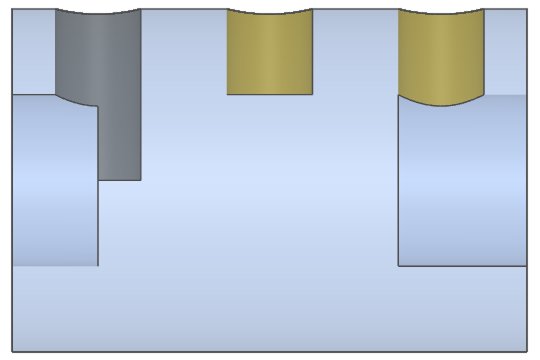

Case 2: Pocket Bottom Radius

Pocket Bottom Radius

| Cause | In some cases, the radius at the bottom of a pocket cannot be machined with an end mill and quotation is not possible. |

| Solution | Remove the radius at the bottom of the pocket from the model to get an automatic quotation. |

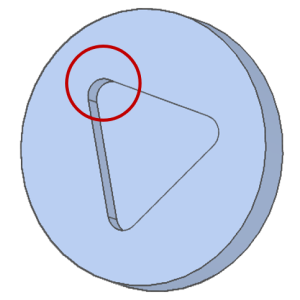

Case 3: Thin Walls

Thin Walls

| Cause | In some cases, thin wall parts cannot be quoted because the accuracy, including general tolerances, cannot be guaranteed. |

The following shapes do not cause an error, but we may contact you to request a modification to the shape or tolerances due to thin walls.

| Solution | If the wall thickness of the model is increased, automatic quotation is possible. |

Click here for more information on the logic that determins thin wall conditions.

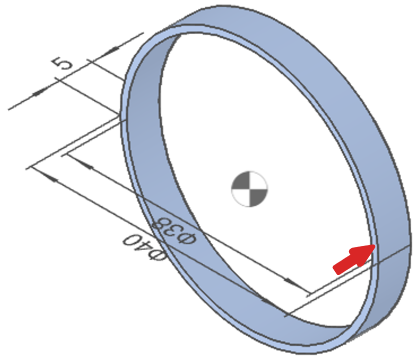

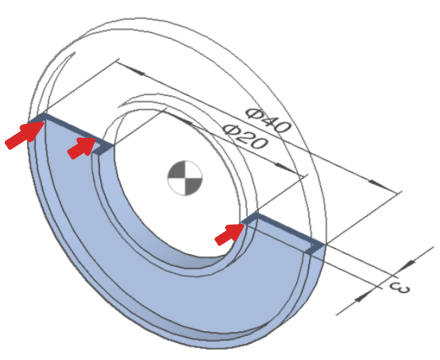

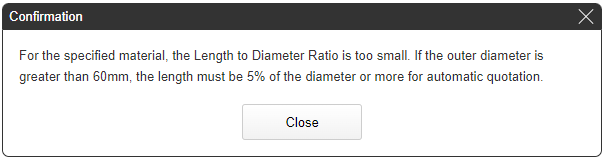

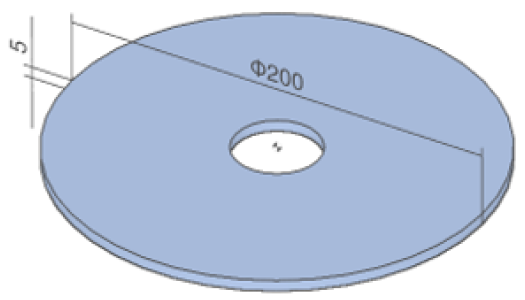

Case 4: Thin Plates

Thin Plates

| Cause | In some cases, thin plates with a total thickness less than 5% of the outer diameter and an outer diameter of ø60mm or more are prone to warping and cannot be quoted. |

| Solution | If the thickness of the model is increased, automatic quotation is possible. |

- Increase the thickness of the model to more than 5% of the outermost diameter for automatic quotation.

- Example Calculation

- Outermost diameter ø60 × 5% = 3mm thickness

- Outermost diameter ø100 × 5% = 5mm thickness

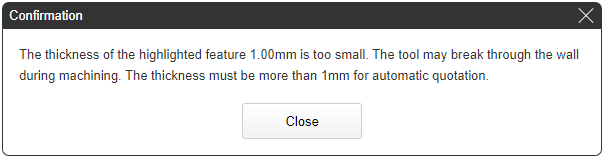

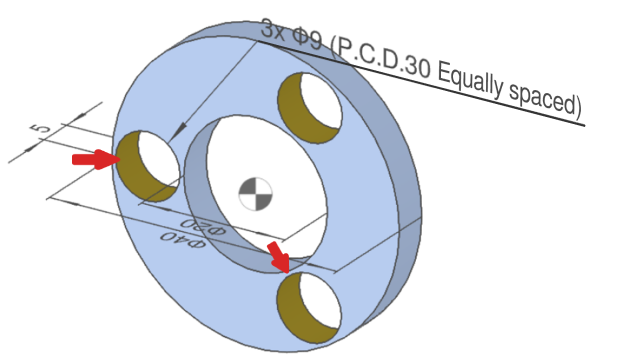

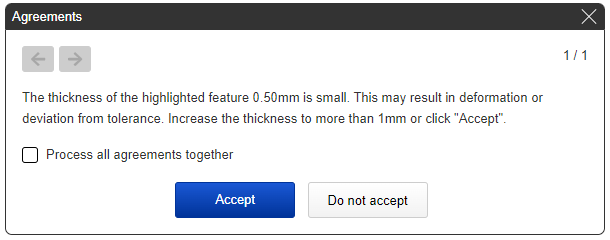

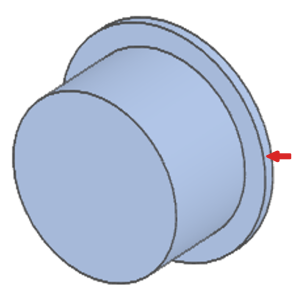

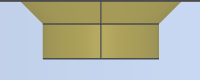

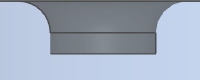

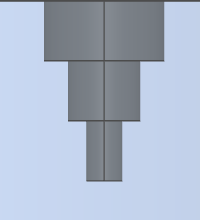

Case 5: The thickness of the edge

Flange Thickness

| Cause | The thickness of the area indicated by the arrow above is less than 1mm. |

| Solution | The thickness must be 1mm or more for automatic quotation. |

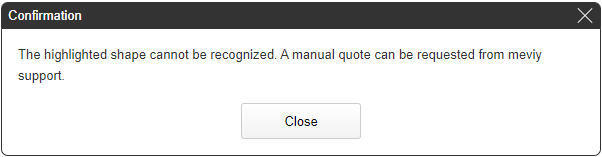

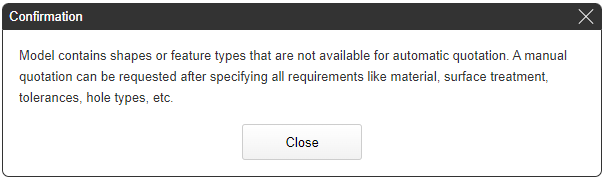

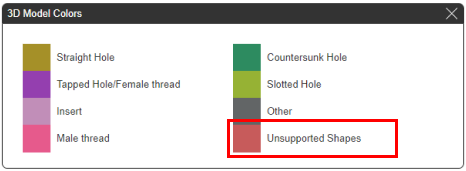

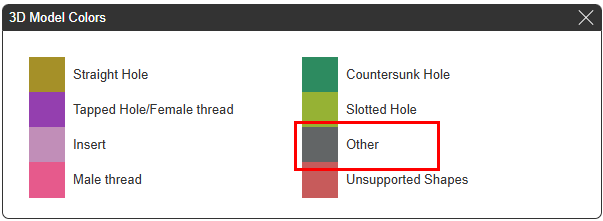

Case 6: Unrecognizable or Unavailable Shapes

The following error messages are displayed when there are unrecognized or unavailable shapes.

*This message may appear for cases other than the following examples.

Unrecognizable or Unavailable Shapes

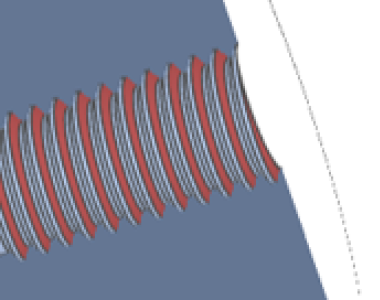

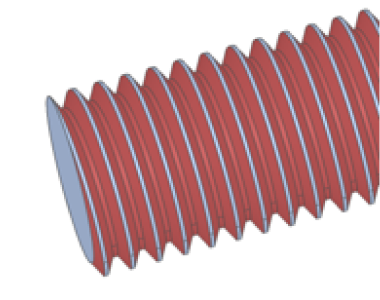

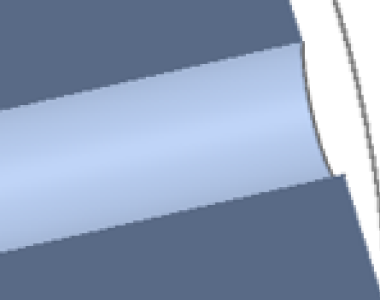

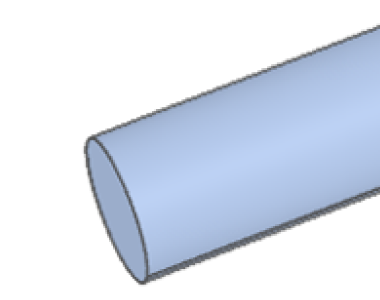

| Cause | Modeled Threads are an unrecognized shape in meviy. |

Internal Thread

External Thread

| Cause | Remove thread modeling and upload as shown below. Threads can then be specified in meviy. |

*Internal threads can be specified.

*External threads can be specified.

- *Threads can be specified in the dialog box after selecting the feature.

- Refer to “Setting Inner Diameter Information” for the setting of internal threads.

- Refer to “Setting Outer Diameter Information” for the setting of external threads.

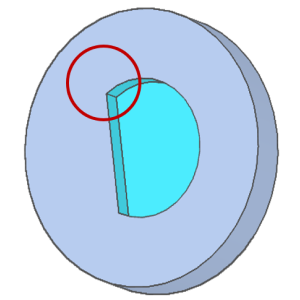

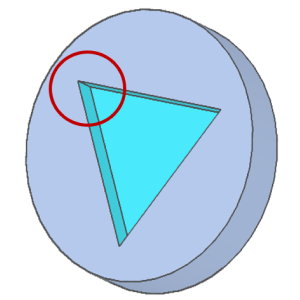

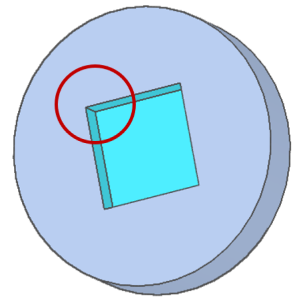

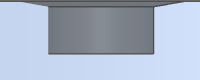

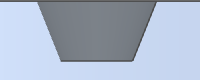

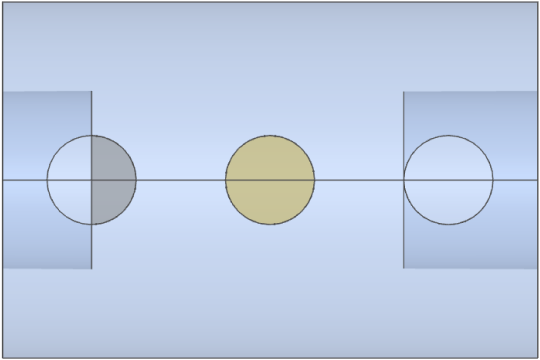

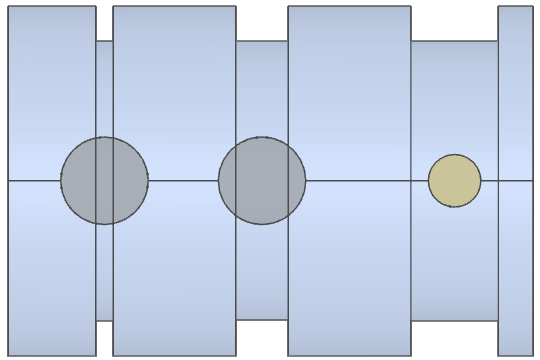

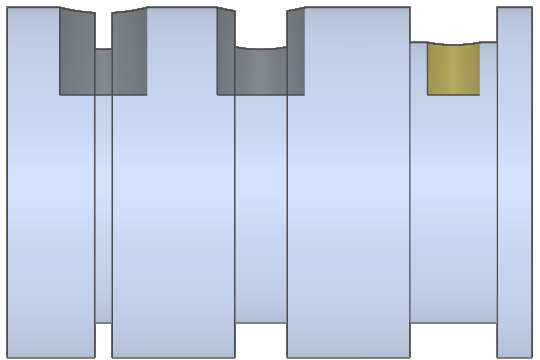

Case 7: Other holes

- If a hole is recognized as an “other hole” in meviy, it cannot be automatically quoted.

- Some examples of hole types that will be recognized as an “other hole” are shown below.

C – Chamfer

Chamfer other than 45

Tapered hole ①

Radius

Tapered hole ②

Tapered stepped hole

Hole intersecting with bore features

TOP

Hole intersecting with outer diameter groove

TOP

FRONT

FRONT

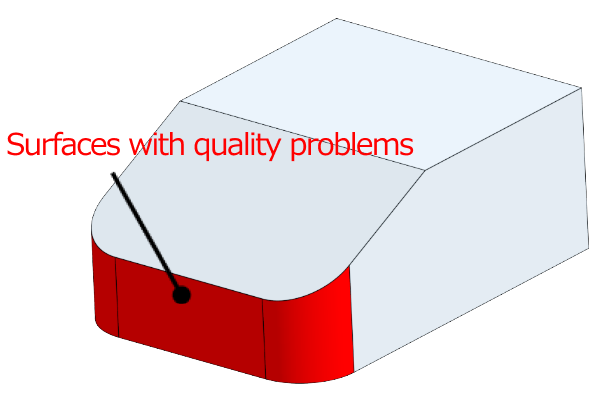

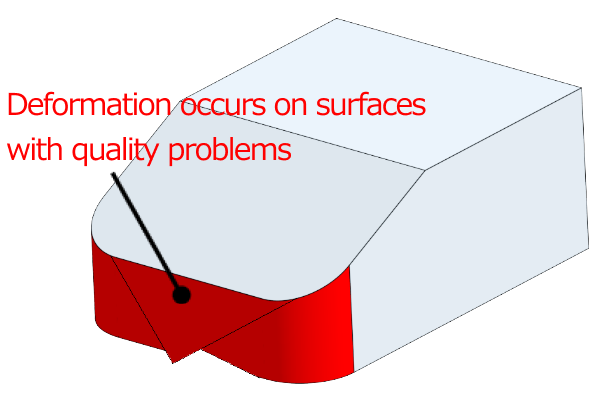

Case 8: Shape recognition failure

- This error occurs when there is a problem with the quality of the uploaded 3D CAD data, and the shape is deformed when it is loaded in meviy.

- If the shape is deformed, please try the following steps to attempt to generate a quote.

State of original data

State after loading in meviy

Tip

- The following message is displayed in the 3D viewer when this error occurs.

- – “An error shape exists in the model.”

- – “Failed to load file.”

1. Check the shape of the uploaded 3D CAD data.

- Check the shape of the uploaded 3D CAD data.

- If there is a problem with the shape, correct it and upload the model again.

Notes

- Visual check

- – Are there any twisted surfaces?

- – Are there any unintended geometric features displayed in the cross-section view?

- – Are there any very small shapes or gaps?

- Check the shape creation method

- – Are there any 3D shapes created without drawing sketches?

- – Shapes created by importing lines from DXF

- – Shapes created using reference geometry or mating part geometry

- – Are there any intersecting lines created by intersecting holes?

- – etc.

- Confirm using CAD checking tools

- – Check for inconsistent shapes

2.Changing the file format

Notes

- – If meviy supports the native format of the 3D CAD file you are using, please try uploading in the native format.

- – If you are using an unsupported format, please try uploading as a STEP or Parasolid.