- HELP

- Technical Information

- CNC Turning

- Applicable Parts/Materials

- Surface Treatment Characteristics

Surface Treatment Characteristics

Surface Treatment – Features / Appearance

| Surface Treatments | Features | Appearance |

|---|

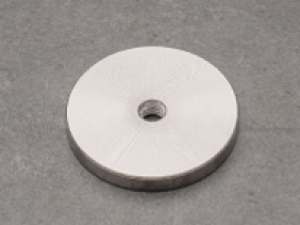

| Electroless Nickel Plating | A surface treatment that forms a protective film through chemical reactions without using electricity. It forms a uniform coating even on complex shapes, maintains high dimensional accuracy, and can be used with a wide variety of materials, including insulators. It is used in a wide range of industries due to its excellent performance. |  |

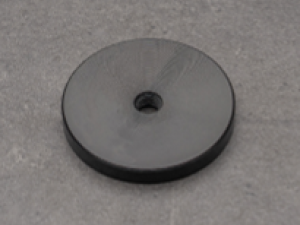

| Black Oxide | A surface treatment that protects the base material by forming an oxide layer on the surface of steel. It prevents the formation of rust on iron surfaces and enhances corrosion resistance. Due to its low cost and excellent appearance, it is widely used in both industrial products and interior applications. |  |

| Trivalent Chromate (Clear) | A surface treatment that forms a chromium layer on a metal surface through an electrochemical reaction. It provides high hardness, wear resistance, corrosion resistance, and a glossy appearance. The chromium layer is a very hard metallic layer that greatly improves the durability and appearance of the material. The chemical conversion process creates a clear colored layer. |  |

| Trivalent Chromate (Black) | A surface treatment that forms a chromium layer on a metal surface through an electrochemical reaction. It provides high hardness, wear resistance, corrosion resistance, and a glossy appearance. The chromium layer is a very hard metallic layer that greatly improves the durability and appearance of the material. The chemical conversion process creates a black colored layer. |  |

| Hard chrome plating(flash Plating) | A surface treatment developed for industrial applications that provides superior hardness, wear resistance, and corrosion resistance compared to conventional chromate treatments. The resulting film reaches a hardness of HV700–1000 and has high wear resistance significantly enhancing the life and durability of sliding components. |  |

| Low Temperature Black Chrome | An electroplating process performed at low temperatures that provides durability comparable to hard chrome. It offers excellent corrosion, wear, and heat resistance equal to that of ordinary chrome plating along with high adhesion that minimizes the risk of cracks in the coating. |  |

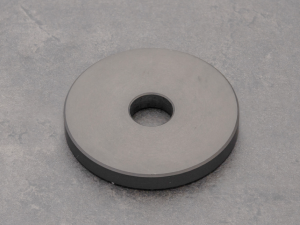

| Phosphate Coating | A surface treatment that forms a phosphate layer on metal surfaces to improve rust resistance, wear resistance, and paint adhesion. It is widely used in automotive and consumer electronics components requiring durability and reliability. |  |

| Salt-Bath Nitrocarburizing | A nitriding process performed below the transformation temperature of steel (approx. 570–590°C), minimizing thermal deformation and maintaining dimensional accuracy. It is used in automotive parts, machinery components, molds, and sliding parts requiring wear resistance, fatigue resistance, and durability. |  |

| Clear Anodize | A surface treatment that forms a thick aluminum-oxide layer on the surface improving corrosion resistance, wear resistance, and electrical insulation. It is especially suitable for aesthetic applications because of its attractive color options. This version is clear and transparent, giving the product a silvery-white color close to the base color of aluminum. |  |

| Black Anodize | A surface treatment that forms a thick aluminum-oxide layer on the surface improving corrosion resistance, wear resistance, and electrical insulation. It is especially suitable for aesthetic applications because of its attractive color options. This version is colored with dyes to give the product a black color. |  |

| Black Anodize (matte) | A surface treatment combining anodizing with blasting and chemical treatment to form a fine texture to achieve a matte effect reducing gloss and light reflection. It is widely used in optical equipment components that require reduced light reflection. It is colored with dyes to give the product a black color. |  |

| Hard Anodize (clear) | A surface treatment that forms a thick aluminum-oxide layer using a low-temperature sulfuric acid solution. It has improved hardness and wear resistance compared to standard anodizing. It is widely used in industrial fields such as automotive and aerospace, where hardness, wear resistance and lubricity are required. The color will range from tan to natural aluminum. |  |

| Passivation | A surface treatment that forms an ultra-thin oxide layer on the metal surface to enhance corrosion resistance. It prevents rust from forming and creates a more uniform appearance and a clean, contaminate free finish. |  |

Surface Treatment Characteristics

| Surface Treatments | Corrosion Resistance | Wear Resistance | Hardness | Appearance / Decorative Quality | Electrical Conductivity |

|---|---|---|---|---|---|

| Electroless Nickel Plating | 〇 | 〇 | 〇 | △ | 〇 |

| Black Oxide | △ | × | × | △ | 〇 |

| Trivalent Chromate (Clear) | △ | × | × | △ | 〇 |

| Trivalent Chromate (Black) | △ | × | × | △ | 〇 |

| Hard chrome plating(flash Plating) | 〇 | 〇 | 〇 | 〇 | △ |

| Low Temperature Black Chrome | 〇 | △ | △ | 〇 | 〇 |

| Phosphate Coating | △ | △ | △ | × | × |

| Salt-Bath Nitrocarburizing | 〇 | 〇 | 〇 | × | × |

| Clear Anodize | 〇 | △ | △ | 〇 | × |

| Black Anodize | 〇 | △ | △ | 〇 | × |

| Black Anodize (matte) | 〇 | △ | △ | 〇 | × |

| Hard Anodize (clear) | 〇 | 〇 | 〇 | △ | × |

| Passivation | 〇 | × | × | △ | × |